|

TOSL Project. A community project to "build a better mousetrap".

by inverseentropy » 1 Jan 2010 23:11 by inverseentropy » 1 Jan 2010 23:11

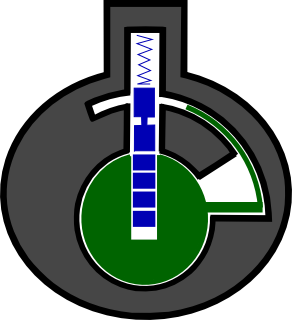

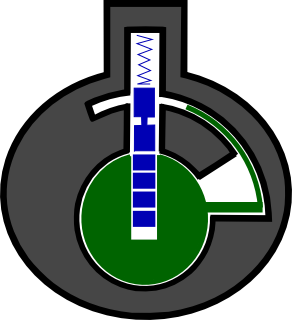

Here is a pin tumber and sidebar lock that I claim to be nearly unpickable (and unfortunately difficult to manufacture):   The gray bits are immovable. The green portion accepts the key and can rotate. The blue bits represent a pin stack. Any key (or even no key) will allow the cylinder to rotate 10 degrees. When the plug rotates, some number of lower pins will be committed to the upper chamber. The green sidebar has tines like a fork and so can pass through the gates in the top pin when the gates are properly aligned using a valid key. The security of this lock relies upon the fact that when the sidebar is touching the pins all of the interesting bits are in the upper chamber, which is not available for manipulation. It may be possible to gain some information about the gates by making very precise measurements of the angle to which the keyway can turn. For this reason it would be good to add some false gates to the pins (I saw a combination lock for a safe that had false gates on the wheels probably for this reason).

-

inverseentropy

-

- Posts: 44

- Joined: 26 Nov 2009 3:08

- Location: Pittsburgh, PA

by FarmerFreak » 1 Jan 2010 23:53 by FarmerFreak » 1 Jan 2010 23:53

I like the idea, very nice.

It does have a few problems. The green piece on the right side should probably be beefed up a bit, to prevent someone from repeatedly forcing it on the wrong combo until it breaks free. The design also has the inherent flaw of not being able to turn a full 360 degrees if need be.

The only other possible problem I see is that it may have too many "small" master pins stacked together. Sometimes that can cause reliability issues.

Despite these possible problems. This is a really nice idea.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by NanoDuke » 2 Jan 2010 7:04 by NanoDuke » 2 Jan 2010 7:04

I don't like that it can spin 10* with any key. One could shim/comb pick up the side of the pin stack, and push up the blue gate pin. On second thought, maybe that'd be harder than I had in mind.

Def get rid of the master pins if possible. What's stopping the user from raising all the pins to the top, applying torque, and slowly drop the pin stacks? Surely the gate pin would then catch at the hole, and pass through.

-

NanoDuke

-

- Posts: 117

- Joined: 26 Jul 2009 6:04

- Location: Sydney, Australia

by FarmerFreak » 2 Jan 2010 11:06 by FarmerFreak » 2 Jan 2010 11:06

NanoDuke wrote:I don't like that it can spin 10* with any key. One could shim/comb pick up the side of the pin stack, and push up the blue gate pin. On second thought, maybe that'd be harder than I had in mind.

Def get rid of the master pins if possible.

It seems that you want to get rid of the two things that make this design work. The ability to turn it 10 degrees with any key is what locks the pins in place. Thus preventing you from being able to manipulate them. This is the basic concept behind Abloy Protec, this is a DBS system for pins, a PBS (pin block system) if you will.  Without the master pins this wouldn't be possible. The tick is to find the correct size of master pin to use. The thinner the master pins, the more combinations can be used. However it also means that it will be more likely to jam up when a pin tries to slip/rotate out of position. The thicker the master pins, the less likely it will be to jam up. But you have less combinations. How many and of what size can be a tough call. NanoDuke wrote:What's stopping the user from raising all the pins to the top, applying torque, and slowly drop the pin stacks? Surely the gate pin would then catch at the hole, and pass through.

The gate pin is going to be stuck in whatever position you lifted it to once you started to turn the plug. If you want to change that position you will need to turn it back to the neutral position, which is when the pins wouldn't be anywhere near the authenticating piece(?)(the green forked piece).

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by Rickthepick » 17 Jan 2010 12:18 by Rickthepick » 17 Jan 2010 12:18

great initial idea.

Im sure you can use this concept to design a lock that is manufacturable

-

Rickthepick

-

- Posts: 1613

- Joined: 24 Sep 2009 4:15

- Location: UK

-

by UEDan » 1 Feb 2010 7:17 by UEDan » 1 Feb 2010 7:17

FarmerFreak wrote:I like the idea, very nice.

It does have a few problems. The green piece on the right side should probably be beefed up a bit

Yep, great idea. But I'm willing to bet a flat head on a socket wrench can break that thing easily.

-

UEDan

-

- Posts: 103

- Joined: 22 Apr 2007 4:13

- Location: Santa Ana California, SoCal

by Phatphish » 1 Feb 2010 16:10 by Phatphish » 1 Feb 2010 16:10

UEDan wrote:FarmerFreak wrote:I like the idea, very nice.

It does have a few problems. The green piece on the right side should probably be beefed up a bit

Yep, great idea. But I'm willing to bet a flat head on a socket wrench can break that thing easily.

To solve this issue, I imagined the cam/actuator part, at the rear of the lock, to be mostly connected to the green bar immediately nearest the plug, and somewhat connected to the central plug. Rather like the anti snap feature on some euro locks, where a slotting saw has cut through most of the "meat" of the lock halfway through the plug. Then if someone applies too much force to the keyway it will snap the plug away from the cam/actuator part at the back of the lock. As the key has limited movement you could also incorporate trap holes in the plug , so if the plug is snapped and travels further than it should, these traps would catch a sprung driver pin. It would mean the lock is not useable, but at least it is still locked and will require lengthy/noisy drilling to rectify. Ive just read this back to myself and can already pick holes in my solution but hey its typed now so you guys may as well read it  <')))><.There are no problems, just situations that require solutions.><((('>

-

Phatphish

- Supporter

-

- Posts: 304

- Joined: 27 Apr 2006 21:17

- Location: Northants, United Kingdom

by 98AB49DC5A » 4 Feb 2010 17:44 by 98AB49DC5A » 4 Feb 2010 17:44

After seeing this design I realized the same principles could be applied to disk tumbler locks.  My design uses a two part plug and two sidebars. One sidebar first locks the inner disks in place then another sidebar tests the outer disks. This design resists the precision measurement attack by using the variable depth of the blocking sidebar to determine the angle at which the outer plug is engaged by the inner plug. It could also be made resistant to a high torque attack by making the blocking sidebar weaker than the locking sidebar. extreme torque would then cause the blocking sidebar to break allowing the inner plug to rotate freely while the outer plug remains locked in place along with it's attached cam.

-

98AB49DC5A

-

- Posts: 46

- Joined: 2 Feb 2010 22:15

by jwhou » 22 Apr 2010 0:16 by jwhou » 22 Apr 2010 0:16

The manufacturing problem could be fixed if you go to a concentric plug in plug design where the inner plug will turn a certain angle before engaging the outer plug and retracting or pushing out an alignment pin between the outer plug and the housing, the rotation will trap the pins between the outer plug and inner plug as desired and both plugs will not rotate relative to the housing till the sidebar or alignment pin has been retracted. I would advise a trap pin between the outer plug and inner plug to prevent the inner plug from rotating enough to retract the sidebar/alignment pin if there is no key in the keyway.

-

jwhou

-

- Posts: 55

- Joined: 14 Apr 2010 21:55

by oORusHOo » 19 May 2010 16:49 by oORusHOo » 19 May 2010 16:49

The idea (commit then authenticate) is great. That's without a doubt the way to go for all future locks.

However, you're looking at this lock from the point of view of a computer security system and not a physical system.

One could 'pick' the lock in a similar fashion to a level lock with a built key.

In other words, one chamber is going to hit the feeling arm first, right - which means that with that pin not set, the lock will turn, say, 33 degrees.

With it set, it will turn 33.1 degrees.

With the next one set, it will turn 33.2 degrees.

So if you have a key which you can build up (replacable pins, like some lever lock picks), you could decode the correct sequence.

Sure you could add fake notches, etc... and although it will frustrate picking, it won't slow it down much.

Also, in order to have variability in this lock, i imagine you would have to have differing radius lengths for your green feelers right?

In otherwords, you'd have holes all along the side of the upper chamber stack, and the green bit for that stack will come out of one of those holes.

That is going to make the lock really fiddly, as I imagine pins will get snagged in those holes.

But you're definitly on the right track! Just think of how to introduce variability between pinstacks, and how to prevent any feedback from a varying levels of 'wrongness'.

A compleatly wrong combo should feel the same as an almost right combo. :3

-

oORusHOo

-

- Posts: 49

- Joined: 7 Nov 2005 18:18

- Location: UK

Return to The Open Source Lock

Who is online

Users browsing this forum: No registered users and 1 guest

|