|

Tool recommendations, information on your favorite automatic and/or mechanical lockpicking devices for those with less skills, or looking to make their own.

by pickmonger » 30 Jul 2006 16:31 by pickmonger » 30 Jul 2006 16:31

I would like some input on some of the possible variables in designing an electric pick gun.

I do not know if even all these 3 factors enter into the usefullness of a given design.

I do know from reading and seeing electric pickguns used that some have qualities, other than operator skill, that make an electric pickgun better or worse at opening locks.

i) Degree of swing

ii) strokes per second

iii) force of the strokes

i) Degree of swing

Assume for a moment that we wanted to optimize an electric pickgun to open a given lock

Its a 5 pin lock with 10 possible depths for the pins .... either 0 to 9 or 1 to 10 depending on how you want to count the depths.

Sample depths in mm

1) 8.610

2) 8.100

3) 7.590

4) 7.110

5) 6.710

6) 6.200

7) 5.690

8 5.210

9) 4.700

10)4.190

Subtracting depth 10 from depth 1 gives us a value of 4.420 mm.

Does that mean the most that the pins have to be bounced up is 4.420.

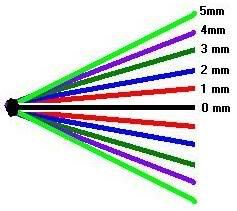

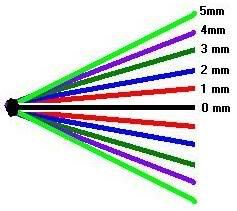

Here is a chart showing some possible values for the swing of the pick needle.

What value (in mm) would be optimal for the extent of the swing of the pick needle.

ii) strokes per second

Any ideas how many strokes or hits per second give optimal performance ?

iii) force of the strokes

When pick needle impacts the pins is there an optimal force in grams per square mm, or what ever measurement of this nature is called?

-

pickmonger

-

- Posts: 464

- Joined: 16 Oct 2003 5:25

- Location: Ontario, Canada

by Biff » 30 Jul 2006 17:02 by Biff » 30 Jul 2006 17:02

I read your post, and have some replies to the different sections. I hope that it's helpful, and that I didn't misunderstand what you wrote in any way.

Degree of swing:

As I understand it, a pick gun works by hitting the lower pins, thereby transferring the energy into the top pins. As a result, the bottom pins don't actually move anywhere. They just sit there like in a pool shot where the cue ball hits a numbered ball dead on and then it just sits there (a stop shot, I think). I think all you need to do is have the pick of the pickgun hit all of the bottom pins at the same time with 'x' amount of force in order to create a time when you can simply turn the plug. I would imagine that the degree of swing would have to be minimal, as long as you hit all of the pins at the same time.

Strokes per second:

In order to determine the maximum number of strokes per second, I think you simply need to take into account the spring force driving the top pins back down in addition to the force of gravity pulling them down. In other words, assuming the top pins go as high as they possibly can in the lock, it will take a certain amount of time for them to settle back down. You wouldnt want the pick to strike the bottom pins before they settled down again, so you wouldn't want the strokes/second too high. I'm sure there's a way to figure this out with some physics equations, but you might be able to use trial and error and possibly a cutaway lock. If you wanted to do it the mathematical way, you have to take into account the force at which the pins are driven up, the force from the spring slowing it down as well as accelerating it back to its normal resting position, and the force of gravity. In this case, you may find that the force of gravity has a negligible effect on the time because it is so minute. You may want some sort of variable resistor to be able to control the speed of the motor.

Force of the strokes:

You could probably determine the minimum force required to launch all of the top pins as high as they can go by taking into account the force of the springs holding the pins down. The optimal ammount of force would be the lowest amount of force required to move the top pins as high as possible, which would help extend battery life. The measurement of this force would probably be in newtons ((kg*m)/(s^2))

If there is anything I typed in here that you want me to try to explain more, I can certainly try. However, someone else on this board might have a better understanding of how pick guns work than I do...I haven't even seen one in person lol.

Any errors in what I said? Don't hesitate to correct me.

Good luck.

-

Biff

-

- Posts: 75

- Joined: 2 Oct 2003 16:34

by p1ckf1sh » 30 Jul 2006 17:28 by p1ckf1sh » 30 Jul 2006 17:28

pickmonger wrote:i) Degree of swing ii) strokes per second iii) force of the strokes[/quote 1) Not really important, as long as it can be set low enough to not hammer the plug body. 2) Important factor 3) Important factor Degree of swing

Assume for a moment that we wanted to optimize an electric pickgun to open a given lock

Its a 5 pin lock with 10 possible depths for the pins .... either 0 to 9 or 1 to 10 depending on how you want to count the depths.

[...depth chart...]

Subtracting depth 10 from depth 1 gives us a value of 4.420 mm.

Does that mean the most that the pins have to be bounced up is 4.420.

Here is a chart showing some possible values for the swing of the pick needle.

[...]

What value (in mm) would be optimal for the extent of the swing of the pick needle.

It does not matter to the needle how long or short the needles are. You are hitting the plug pins to bounce the shell pins. In the ideal case the plug pins stay where they are. If the swing of the needle actually pushed the plug pins too far you might block the shearline with that plug pin. If you want to calculate the maximum allowed swing for a given lock measure the distance between the tips of the plug pins and the first obstructing ward in the keyway that the needle would hit when positioned. Any ideas how many strokes or hits per second give optimal performance ?

[...]

When pick needle impacts the pins is there an optimal force in grams per square mm, or what ever measurement of this nature is called?

This is hard to say in a general manner. These two factors are in a kind of relation. The variables that dictate the optimal setting for the electric pick in a given lock:

a) length and counterforce of spring

b) friction of the lock, in this context the friction the pins have against the pin bore holes (chamber walls)

The spring force variable can be measured or approximated for any given lock or lock series, as long as it has not been repinned. The friction part is tricky, because dirt, WD40, graphite and all the other stuff that might have been assimilated in the lock will change this property.

The relation of stroke force and stroke frequency is as following (as I see it). In a lock with a strong spring force you need a higher stroke force to send the shell pins upward for a duration long enough to get the plug turning. Considering a lock with high-low pinning the time window is smaller compared to an equal lock with a flat pinning. This is because some of the pins will travel longer to pass the shearline. So, imagine a minimal force of 1, that will send all pins to shearline. When the last pin (that travelled farthest) passes the line another one that did not have to travel that far might already be on the way back. So, with the imaginary value of 1, you have time window of 1 ms. If you crank up the force to like 1.10 this might give you a time window of maybe 5ms, because when the last pin (the one with longest travel) passes shearline another pin that passed earlier might not be on the way back yet.

The frequency of the strokes relates to it like this: If you have a stroke force that creates a timewindow of 8ms and a stroke frequency of 5ms that means you strike the plug pins again when the shell pins are still moving. This will result in the shell pins moving and possibly blocking the shearline or at least not resulting in a hit on the shell pins. Now, let's say you have a timewindow of 8ms and you have all the pins settled back to rest position after 12 ms. The ideal frequency would then be 13ms, because in that setting you would essentially create an almost permanent shearline, because with every stroke of the needle an opening possibility would be created. (Well, take the almost permanent shearline with a grain of salt...  )

Am I making sense? Due to financial limitations the light at the end of tunnel has been turned off until further notice.

-

p1ckf1sh

-

- Posts: 711

- Joined: 16 Mar 2006 9:55

- Location: North Germany, Europe

by Shrub » 30 Jul 2006 17:59 by Shrub » 30 Jul 2006 17:59

I think my imput has already been covered but ill say it anyway incase it helps,

The contributing factors are as said the frequency and force (snap)

To improve an existing pickgun you could improve the force that the pick needle snaps at, this can be done in a couple of ways,

The spring can be made stronger and the speed the object that moves the 'yoke' move off the yoke increased,

Increasing the spring weight is a good way of quickly upping the performance, to mess around with the 'yoke' strike speed can mean one of three things, increase the off-set on the bearing or the size of it, the other thing is to increase the speed of the motor driving it,

This creates a few more problems, increasing the speed of the motor simply means there is more of a chance of the bearing coming round agine before the yoke has fully hit the stop thus actually removing some of the snap,

Increasing then offset of the bearing means the pick blade will now move more from rest to its full height which can cause other mechanical problems in the gun without counting the problems you get in the lock,

Increasing the size of the bearing on the yoke means that there is a greater chance of getting it wrong by just a little bit which would mean that you are actually pushing the yoke against the stop which again is undesireable,

In the past what i have done on repairs is to slightly increase the bearing on the yoke size and also increase the spring weight, this gives a heavy hard snap as far as the mechanics already in use goes,

This does leave an issue though that a looser lock may get the bottom pins bounced past shear which you dont want so you need to be able to adjust the rate of snap now youve made it more efficent,

The commercial ones do this by stoping the yoke from lifting too far up thus making the weight of the snap lighter but its not an idea as far as im concerned as this can also alter the effectiveness to an extent, thats why the cheaper guns work better on a near full setting with a very fine line between it workig and it not,

The ideal in my eyes would be to actually alter the strength of the spring and leave the yoke to achieve its full travel each time with the correct rotation of the cam on the bearing,

To increase the frequency is not actually what is needed, if the snap is enough all you would have to do is make sure your on the pins enough for it to effect, the fact your trying to 'bump' the lock 20 times a second or 10 times a second doesnt actually matter,

In summery, make the gun adjust via the spring, make the cam bigger than the bearing, make the offset on the cam slight more than a lot,

But then thats only my opinions,

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by pickmonger » 31 Jul 2006 2:44 by pickmonger » 31 Jul 2006 2:44

I was reading some where that one of the differences between a manual pickgun like the majestic or a snap pick and an electric pickgun was that the manual device only relied on the impact on the bottom pins to bounce the upper pins above the shear line.

Conversely, the electric pickgun both used the impact to bounce pins up and also could be used to physically lift the pins into position, like when picking pin by pin with a lifter.

That is why I was asking about the degree of swing which would be a factor if the latter was true (be used to physically lift the pins into position)

-

pickmonger

-

- Posts: 464

- Joined: 16 Oct 2003 5:25

- Location: Ontario, Canada

by Shrub » 31 Jul 2006 9:41 by Shrub » 31 Jul 2006 9:41

Thats not true as far as im concerned or aware, what if its a low cut? you would be oversetting the pins,

You do lift the pins slightly with a gun and then operate it but the use of a manual or electric gun is the same imho,

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by SEVEN » 31 Jul 2006 18:30 by SEVEN » 31 Jul 2006 18:30

Whitch is the best electric pickgun on the market at the moment.

-

SEVEN

-

- Posts: 150

- Joined: 14 Jun 2006 19:25

- Location: Newcastle Upon Tyne

by Shrub » 31 Jul 2006 18:41 by Shrub » 31 Jul 2006 18:41

The Multi pick one with the adjustable speed box but as for handheld the Wendt is currently top dog until a new one is brought out

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

Return to Lock Pick Guns, EPGs, Snappers

Who is online

Users browsing this forum: No registered users and 1 guest

|