|

Tool recommendations, information on your favorite automatic and/or mechanical lockpicking devices for those with less skills, or looking to make their own.

by TOWCH » 10 May 2005 1:25 by TOWCH » 10 May 2005 1:25

I like the punch idea. It reminds of a impact punchdown tool I've used while terminating CAT5 cable. How I would do it would be take a blank, cut to half a cut higher than all lowest cuts, and fix it to the punchdown tool. The problem with this setup is the force is transfered into the rest of the lock as much as the pins. So I would bore out the inner part of the blank so that I could put another tube inside the keyblank. Drop a belleville spring down there for the tube to rest on. Make the inner tube half a cut depth longer than the blank so that the keyblank cuts are all low cuts when the tool is at rest. The spring would have to be strong enough to resist giving under the force of pushing down the pushdown tool, but just barely so that when the punchdown tool goes off, it pushes the belleville spring the rest of the way, allowing the keyblank to bounce the pins. I hope someone was able to understand that because it was difficult to explain.

-

TOWCH

-

- Posts: 1587

- Joined: 20 Jul 2004 0:19

- Location: Oregon

by Peaky » 10 May 2005 4:18 by Peaky » 10 May 2005 4:18

Orange, im sorry but you have missed the jist of my posts,

The drill will not be turning, when the torque part of the drill is working you get a strong vibration but the chuck does not turn,

The wind up motor is also not for turning, it is fastened to the pick and an offset weight on the output shaft will vibrate the pins,

You do not turn a pick in a tubular lock like you are suggesting or else you will wreck the lock,

You put a slight tension on and vibrate the pins, you do not scrub them or rake them,

Its up to you all what you do but none of the posts after my last one will work imho,

Tubular lock springs are more or less the same weighting as normal cylinder ones but obviously you are pushing them all together,

The spring does not have to be strong as NO turning torque is needed, the units as they come out of the toys DO NOT have to be modified,

Pip, sorry but an electric toothe brush is only good for cleaning your teeth but if you succeed where most have failed before, it would make a good thread,

Towch, again i am sorry but the lock will be destroyed after 1 or 2 'punches' of the lock,

What you are all missing is the fact that a rotational force can not and should not be used, this is purely for vibrating the pins like you would with a pick gun on a cylinder lock,

You can not use a rotation technique anyway as the centre plug needs the tension and if somthing is spinning around that then you can not keep tension on.

Re-read my posts on this thread until you understand them, alternitively read up on electric pick guns an how they work as a few of you are missing the point,

I will take a back seat on this now so good luck to you all.

-

Peaky

-

- Posts: 459

- Joined: 24 Oct 2004 10:43

- Location: Derbyshire, UK

by Mad Mick » 10 May 2005 18:07 by Mad Mick » 10 May 2005 18:07

TOWCH wrote:I like the punch idea. It reminds of a impact punchdown tool I've used while terminating CAT5 cable. How I would do it would be take a blank, cut to half a cut higher than all lowest cuts, and fix it to the punchdown tool. The problem with this setup is the force is transfered into the rest of the lock as much as the pins. So I would bore out the inner part of the blank so that I could put another tube inside the keyblank. Drop a belleville spring down there for the tube to rest on. Make the inner tube half a cut depth longer than the blank so that the keyblank cuts are all low cuts when the tool is at rest. The spring would have to be strong enough to resist giving under the force of pushing down the pushdown tool, but just barely so that when the punchdown tool goes off, it pushes the belleville spring the rest of the way, allowing the keyblank to bounce the pins. I hope someone was able to understand that because it was difficult to explain.

You got the idea then? The belleville spring is a concave/convex washer, depending upon which way you look at it, if I understand you correctly? Hitting the pins full-face should be far easier with a tubular setup, as the pins are already partially exposed. The torquing of the plug could be difficult to achieve though...what about a sleeve around the keyblank which has a helical groove & a pin in the blank. The idea being that the backlash from the blank applies rotation to the plug. The angle of the helical groove could be a real pain to get right though.  If it ain't broke.....pull it down and see how it works anyway!

-

Mad Mick

-

- Posts: 2314

- Joined: 8 Jan 2004 19:19

- Location: UK

by TOWCH » 11 May 2005 2:53 by TOWCH » 11 May 2005 2:53

That was what I was refering to, I don't have a lot of experience with them, but it seems like the easiest way to concentrate the force on the pins. The first thing that came to mind when I was trying to think of something that would work was the howstuffworks article on anti tank landmines. I looked that up and it told me those were called belleville springs. I hadn't given tension a lot of thought but now that you mention it, it seems like you could just use the keyblanks original tab and cut a channel in the inner tube for it. Then rotate the tool immediately after it goes off. It seems like this might be a bit difficult to do properly just twisting the tool so maybe attaching a lever handle would help with control. As for destroying the lock, I don't know. I hear bump keys in general can do that, so until it was actually tested I don't think there's any way to know how much damage it would actually do.

-

TOWCH

-

- Posts: 1587

- Joined: 20 Jul 2004 0:19

- Location: Oregon

by Mad Mick » 11 May 2005 21:02 by Mad Mick » 11 May 2005 21:02

What I'm thinking, is utilising the backward snap of the tubular key blank and tranferring it into a turning force via the helical groove in an outer sleeve. When using an automatic centre punch, the push force overcomes a spring inside the punch, which allows the main body to be moved towards the workpiece, resulting in a further spring action which causes the tip to rise from, then re-strike the surface to be marked. This action must surely create a momentary reactionary bounce back from the struck surface, which may be used to induce a turning force by some means...like a carefully calculated helix. The mathematicians/engineers amongst us would be the ones to consult here.

If it ain't broke.....pull it down and see how it works anyway!

-

Mad Mick

-

- Posts: 2314

- Joined: 8 Jan 2004 19:19

- Location: UK

by pip » 11 May 2005 22:28 by pip » 11 May 2005 22:28

.

huh...

.

-

pip

-

- Posts: 491

- Joined: 24 Apr 2005 9:53

- Location: Ontario Canada

by Mad Mick » 12 May 2005 16:54 by Mad Mick » 12 May 2005 16:54

Yeah, looks and sounds confusing when re-read

I know what I mean in my head...at least I did before the beer kicked in.  If it ain't broke.....pull it down and see how it works anyway!

-

Mad Mick

-

- Posts: 2314

- Joined: 8 Jan 2004 19:19

- Location: UK

by Mad Mick » 15 May 2005 17:25 by Mad Mick » 15 May 2005 17:25

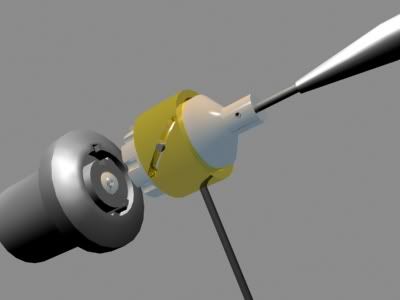

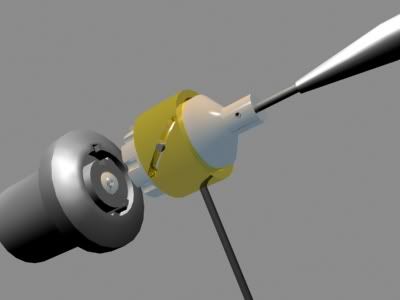

Does this help to explain things better:

If it ain't broke.....pull it down and see how it works anyway!

-

Mad Mick

-

- Posts: 2314

- Joined: 8 Jan 2004 19:19

- Location: UK

by digital_blue » 15 May 2005 17:29 by digital_blue » 15 May 2005 17:29

Not a bit, but it's fantastic to look at!

db

-

digital_blue

- Admin Emeritus

-

- Posts: 9974

- Joined: 6 Jan 2005 15:16

- Location: Manitoba

-

by vector40 » 15 May 2005 18:02 by vector40 » 15 May 2005 18:02

Animate it!

-

vector40

-

- Posts: 2335

- Joined: 7 Feb 2005 3:12

- Location: Santa Cruz, CA

by MrB » 15 May 2005 18:15 by MrB » 15 May 2005 18:15

That picture is just too cool. Have you been taking graphic art classes or something?

-

MrB

-

- Posts: 716

- Joined: 7 Sep 2004 15:13

- Location: Southern California

by NKT » 15 May 2005 18:16 by NKT » 15 May 2005 18:16

What 3D modelling software do you use, Mick?

I can see the idea of a bump-key-like tool for a tubular lock, but what's the point? Most can be opened in a short time by the normal tool, and any bumper machine is likely to cost just as much?

Loading pithy, witty comment in 3... 2... 1...

-

NKT

-

- Posts: 1273

- Joined: 13 Feb 2005 16:35

- Location: West Mercia, England

-

by GateTwelve » 15 May 2005 19:43 by GateTwelve » 15 May 2005 19:43

Mick, if it's any consulation...I get exactly what you mean. But that's only because my day at work has been extremely slow, and I pondered your paragraph and drawing for about ten minutes.

-

GateTwelve

-

- Posts: 199

- Joined: 27 Jul 2004 17:49

- Location: North Dakota

by HeadHunterCEO » 15 May 2005 21:42 by HeadHunterCEO » 15 May 2005 21:42

Mad Mick wrote:Does this help to explain things better:

CAD?

nice Doorologist

-

HeadHunterCEO

-

- Posts: 1262

- Joined: 7 Apr 2004 21:10

- Location: NY,NY

Return to Lock Pick Guns, EPGs, Snappers

Who is online

Users browsing this forum: No registered users and 1 guest

|