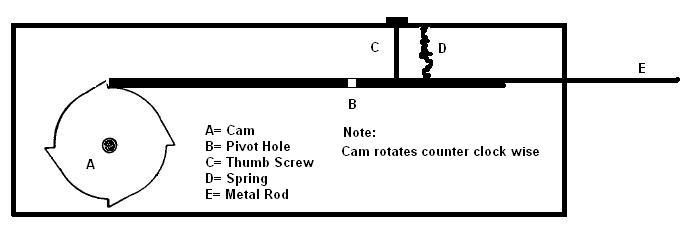

Unlike the standard eletric pickgun that we normally see, here is an idea I am toying with. Instead of the off center pin at the end of a shaft, what about using a cam shaped to impart the up down motion?

A= a cam shaped to impart a up down motion to rod E. when the cam is rotated counter clockwise. B is the pivot point for rod E .... C is a thumbscrew that exerts a downward pressure on the rod (to adjust the amount of up and down action) and D is a compression spring that pulls up on the rod and keeps it against the cam.

The shape of the cam can be varied to give a different up and down motion.

I think that the motor and cam can be rotated 90 degrees so that the pickgun conforms to the usual shape or maybe running the motor at the side will work fine.

This is modified from a design copied from Eddie the wires material. Due to copyright issues I can't just copy his diagram.

Wire mentions that the cam be made of a piece of plexiglas 6 * 12 inches, 1/4 inch thick and the cam protrusions be 3/16 of an inch.