Okay, so here's my idea for a concept lock. It's probably not "pick proof" but it would be a complete pain in the ass to pick / bypass.

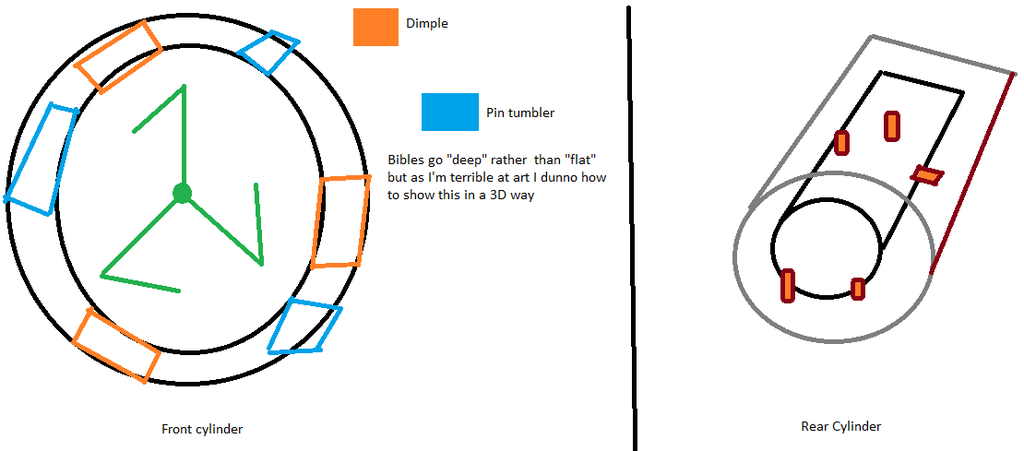

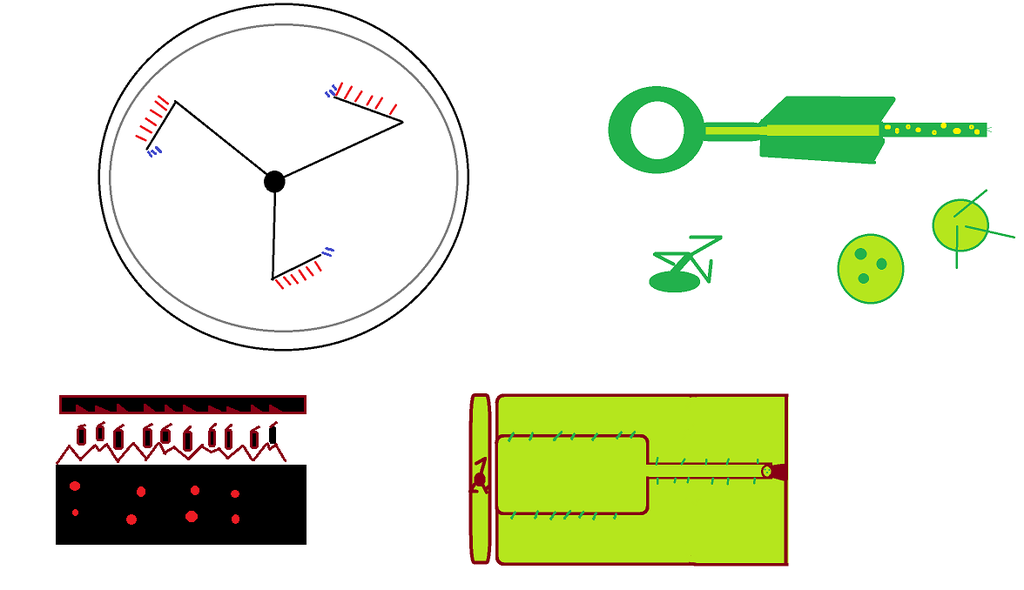

The keyway has a central round hole, and three arms coming off of that. Each of those arms then has another arm slanted 45 degrees back towards the lock, each in the same direction, forming a sort of fan shape. The outer edges of each of the slanted arms would be where the bitting on the key is located - this would need to use some kind of dimple system.

I'm thinking maybe 6-8 pins per arm, for 18-24 pins for the whole thing. Each arm would use one standard pin, and then a mixture of spools, serrated, mushroom etc. Hoping for around 4 pin depths. I'd probably throw a magnetic pin or two in there as well.

Along with the wide sections of each arm, the edges of each arm would be cut into a traditional pin tumbler system. These would have around 6-10 pins each and as above would be a mixture of security pins with one standard. I'd be hoping for around 8 pin depths on these. This would also utilise a rotating pin system with sidebar, similar to a Medeco.

It goes without saying that each arm would be different and therefore the spacing of the arms would be such that the key could only go in one way correctly.

The very front of the lock would be a hardened anti-drill plate which is free-spinning and no less than 5mm thick. The lock cylinder would be located behind this and the key would have a section of plain round barrel immediately after the bow in order to clear this plate.

However, the lock section described above would NOT rotate the lock. It would instead only free this section of the plug from the housing. There would be ANOTHER part of the lock, this will be a fat cylinder (for lack of a better word) at the back of the lock. At the end of the Tri-Key, it will taper down into a cylindrical section (Google "Golden Mean Circular Padlock", except it would use dimple cuts instead) which would fit into another cylinder at the back of the lock.

This cylinder would be linked to the front one but would be mostly shielded from it, except for a small hole for the key, which is the purpose of the round hole at the front of the lock, since the "extra" cylindrical key would be placed at the immediate end of the main key shaft.

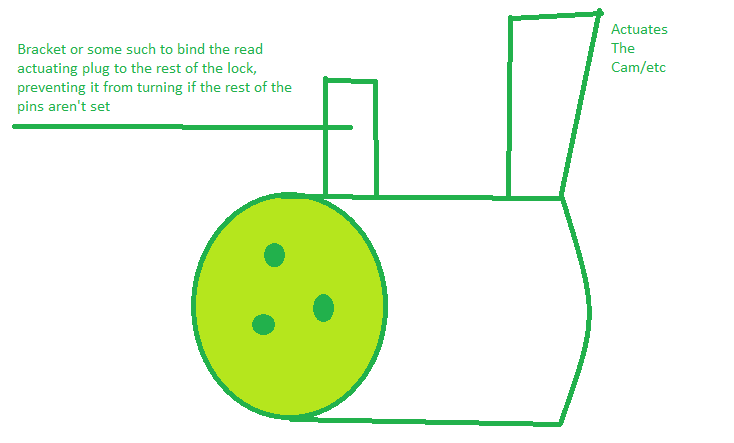

This back cylinder would use dimple pins, security and standard and the cuts could cover the entire circumference of the key. Probably 10 in total. At the very end of the key would be three small round pins, which would sit into a round plug at the very back of the lock. These would actuate a simple locking mechanism similar to a "van lock", or the Grumm Geminy shield, but this would also be the means to actuate the entire cylinder and unlock the lock. This means that placing tension on any part of the lock except for this small plug right at the very back of the lock would not result in any turning motion, making picking much harder.

The cam or device to be actuated would be installed directly behind, or maybe around, the back of the cylinder and actuated by the end plug which provides the lock tension. The intention would be that the lock needs rotating several times - maybe in a safe to withdraw three bolt throws, or something similar - to force an attacker to continually have to re-pick the entire thing.

In total, an attacker would have to face:

Anti-drilling: free-spinning, hardened (maybe embedded with drill bit deflecting chips) front plate. Pins also to be made of a hardened material such as stainless steel.

Anti-snap: As this is a round cylinder embedded further back into the lock it should not be susceptible to the same issues as a Euro cylinder. However the cylinder should contain hardened rods and anti-drilling pins.

Picking: Apart from the lack of tension (only three small round holes in a plug at the back of the rear cylinder) The attacker would face an awkward keyway, LOTS of pins, dimple and pin tumbler as well as a sidebar system. I'm sure it COULD be picked, given time.

Master Keying: As far as the quantity of pins is concerned, even on a conservative reading of the above you're looking at:

Key blade dimple pins: 6 per arm, 4 pin depths. That's 18^4 = 104,976 differs

Key blade regular pins: 6 per arm, 8 pin depths. That's 18^8 = 11,019,960,576 differs

Rear locking cylinder: 10 pins, 4 pin depths. That's 10^4 = 10,000 differs

My math could be out - not sure if I'd need to calculate the total pins and the total depths and somehow work out the differs from there, but even just adding the above three together that gives us over 11 billion differs. It could be massively more than that. We're looking at minimum 46 pins total with 4-8 pin depths minimum. 46^8 would be over 20 trillion differs so the number is somewhere between those two - easily enough for extensive master keying possibilities.

Predicted FAQs:

1q. How the hell do you pin this thing?

1a. With difficulty! Haha. Likely it would be put together by a machine and you'd need a machine to re-pin it due to the bibles needing to be at different angles inside the lock.

2q. How does it actuate the cam?

2a. Not 100% sure about this yet. I suspect somehow the rear plug which tensions the lock would also actuate the cam. Maybe something like this:

3q. What stops the rear plug from being rotated independently of the rest of the lock?

3a. It would be attached to the rear cylinder, which is attached to the front cylinder - it must all be able to turn (by clearing the shear line) before the end plug can turn.

4q. Where do all the bibles sit?

4a. Here's a rough diagram, bear in mind that I can't draw!