|

TOSL Project. A community project to "build a better mousetrap".

by FarmerFreak » 11 Oct 2009 9:11 by FarmerFreak » 11 Oct 2009 9:11

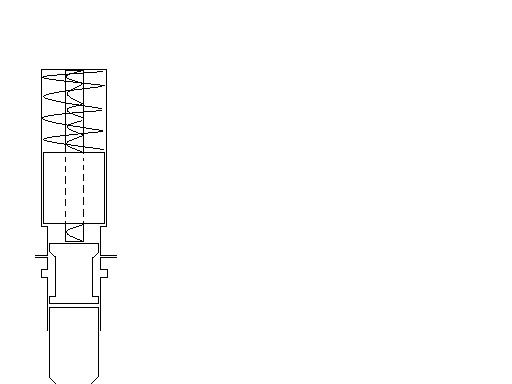

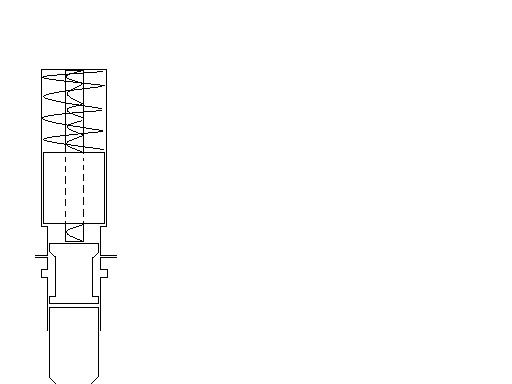

The idea is to have a driver pin inside of a driver pin. The inner driver pin spring must be weaker than the outer driver pin spring. So that under regular use the pins are connected as one pin. But when bumped, the idea is that the bottom driver pin would be pushed down while the top driver pin continues upwards. Disclaimer: This may not work at all. At this point in time it is nothing more than a Sunday morning idea.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by unlisted » 11 Oct 2009 11:42 by unlisted » 11 Oct 2009 11:42

FarmerFreak wrote: The idea is to have a driver pin inside of a driver pin. The inner driver pin spring must be weaker than the outer driver pin spring. So that under regular use the pins are connected as one pin. But when bumped, the idea is that the bottom driver pin would be pushed down while the top driver pin continues upwards. Disclaimer: This may not work at all. At this point in time it is nothing more than a Sunday morning idea.

Until someone proves it does not work, I like that idea...

-

unlisted

- Moderator Emeritus

-

- Posts: 3131

- Joined: 27 May 2006 0:42

- Location: Canada

by LocksmithArmy » 11 Oct 2009 12:48 by LocksmithArmy » 11 Oct 2009 12:48

Thats a really good idea. the only proble I see with it is if you tried to do it on smaler pins and during the bumping process you got the top of the driver pin above the shear line and the botom of the driver pin below the shear line. it would murder that little spring. but if you stayed only doing this to the longer drivers you shouldnt have this issue.

nice work

-

LocksmithArmy

-

- Posts: 989

- Joined: 25 Jun 2009 22:14

-

by mhweaver » 11 Oct 2009 19:10 by mhweaver » 11 Oct 2009 19:10

LocksmithArmy wrote:Thats a really good idea. the only proble I see with it is if you tried to do it on smaler pins and during the bumping process you got the top of the driver pin above the shear line and the botom of the driver pin below the shear line. it would murder that little spring. but if you stayed only doing this to the longer drivers you shouldnt have this issue.

nice work

If you didn't want to be forced to make the pins longer, you could include some kind of catch to keep the inner driver pin from totally exiting the out pin. As an added bonus, this would double as a security pin. I imagine with a little tweaking, it would be a pretty nasty one to deal with too

-

mhweaver

-

- Posts: 9

- Joined: 9 Aug 2009 0:15

- Location: Idaho, USA

-

by MacGyver101 » 11 Oct 2009 19:52 by MacGyver101 » 11 Oct 2009 19:52

I honestly don't have enough experience with that sort of arrangement to know for sure... but I have seen a handful of people reporting that they've bumped open Mul-T-Lock cylinders -- and I think what you're proposing for your drivers are a similar arrangement.

I think the problem would be in completely eliminating any friction between the outer "shell" and the inner pin: it wouldn't take much contact on the side-wall of the "shell" for them to start acting like a single unit and traveling together.

-

MacGyver101

- Moderator Emeritus

-

- Posts: 1560

- Joined: 21 Jun 2006 14:40

- Location: Toronto, Canada

by FarmerFreak » 12 Oct 2009 11:20 by FarmerFreak » 12 Oct 2009 11:20

I got a chance to play with this idea this morning. It didn't work. I was testing it on a sc1 keyway cut away with a pick gun. Not an actual bump key. But whatever.

I tested a few different variations of an upper and bottom driver pin. Different springs for both pins, sometimes the pins resting positions they were connected, othertimes the pins were separated by the spring. The idea being to transfer the motion of the bottom driver to the top driver after being hit.

I like the theory, but in practice I can't make it work.

I wasn't worried about trying to make it not jam up. Though it didn't, that was just something that I wasn't going to think too much about unless I could get it to have the desired effect.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by MacGyver101 » 12 Oct 2009 18:38 by MacGyver101 » 12 Oct 2009 18:38

I wouldn't give up too easily: I really do think that you're on to something with the "moving element" idea.

There are some very effective recoil-absorbing systems for shotguns that use a mercury-filled tube: a portion of the recoil energy is initially transferred into the liquid mercury, which takes some time to flow from one end of the tube to the other -- the effect of which is to spread out the recoil energy over a greater period of time, so that it feels less intense for the shooter. I'm not suggesting mercury-filled drivers... but some similar moving weight may be a good way to "spread out" the force of the bump-key strike.

I wonder if a hollow capsule containing ball bearings (or something similar, to keep the friction at a minimum) would work? (Although that would likely introduce some weaknesses that could be exploited on the destructive-entry side of things.)

-

MacGyver101

- Moderator Emeritus

-

- Posts: 1560

- Joined: 21 Jun 2006 14:40

- Location: Toronto, Canada

by Rickthepick » 13 Oct 2009 4:47 by Rickthepick » 13 Oct 2009 4:47

Im not sure this would work although appears at first glance to be a good idea.

Combining the resistance of two springs will only act the same as a single spring with a different resistance, im pretty sure that the bumping force will not pass through one spring and then through another, it will be absorbed by both together as a combined effort. Therefore why not just use a single spring providing the correct resistance in the first place, and back to square one.

The key to combating bumping is to design a lock that can absorb all the energy in the 'bump' before the springs do, quite taxing if your going to design a solid metal lock.

-

Rickthepick

-

- Posts: 1613

- Joined: 24 Sep 2009 4:15

- Location: UK

-

by FarmerFreak » 13 Oct 2009 7:53 by FarmerFreak » 13 Oct 2009 7:53

I think this idea stands a good chance of working. Again the basic premise is to transfer the motion from the bottom driver pin to the top one after being hit. Since I can't stop the bottom driver from moving at all. Let's work with it instead. Once the bottom driver hits the top driver, a lot if not all of the motion should be transferred. At that point the bottom driver should be lined up with a false gate, thus preventing repeated bumps from slowly edging it up to the correct shear line. Yes I stole the false gate setup from the Assa design. It's a good design. The center spring would likely be placed inside of some kind of a telescoping tube. Otherwise there will likely be problems. Though a prototype to test the theory likely wouldn't need it. The only problem I see with this design is that we need to modify the cylinder/housing.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by mcm757207 » 14 Oct 2009 13:32 by mcm757207 » 14 Oct 2009 13:32

The idea seems similar to Master Lock's BumpStop: separate the bottom pin from the top pin so the energy is dissipated after being bumped.

-

mcm757207

-

- Posts: 1468

- Joined: 12 Jan 2004 22:02

by FarmerFreak » 16 Oct 2009 15:02 by FarmerFreak » 16 Oct 2009 15:02

Yes, this is very similar to Master lock's BumpStop. But it has one significant difference. You can't easily decipher which pin(s) are bump resistant by looking into the lock. You'd have to pay close attention and feel for the second spring. Of course a lock could be keyed with one of these in each chamber. Different size driver pins of course. I guess the BumpStop could be to. And pending how much larger in diameter the top driver pin is to the bottom one. We could add some anti-impression bottom pins.  Anyway I tested this. As far as I can tell it works. The bottom driver is an Assa driver (cut down to size). The top driver is a Medeco #6 master pin (with a hole drilled through it). The inner spring is an older Chevy wafer spring. And I tapped threads into the bottom chamber to give it that all too familiar Assa false set.    I couldn't get it to turn with a bump key, even when this was the only pin chamber used. However, a co-worker was able to get it with a pick gun (fully pinned). But to be fair, he had to over lift all of the pins and then click them on their way down....It took a couple of tries.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by darklighterz7611 » 19 Dec 2009 13:09 by darklighterz7611 » 19 Dec 2009 13:09

Problem is that if only a few of the pins are bump resistant it becomes feasible to do an advanced bump key. So really i think its got to be an all or nothing thing. or atleast more than 70% bump resistant so as to make the advanced bumping less feasible and more time consuming. and correct me if im worng but with the image posted by farmer freak wouldn't it be better if the driver pin and the one above it (anti bump pin?) was touching. that way all of the force would be transferred from the driver pin to the anti bump pin, where'as in the image the gap would hamper part of this transference and enable the driver pin to move atleast a little.....which is too much

-

darklighterz7611

-

- Posts: 120

- Joined: 18 Dec 2009 13:55

- Location: United Kingdom

by darklighterz7611 » 19 Dec 2009 13:14 by darklighterz7611 » 19 Dec 2009 13:14

Sorry just realised that everything i said has already been covered  gonna blame the last post on tiredness and be off

-

darklighterz7611

-

- Posts: 120

- Joined: 18 Dec 2009 13:55

- Location: United Kingdom

by jwhou » 14 Apr 2010 23:19 by jwhou » 14 Apr 2010 23:19

Seems to me that this would work by changing the rate at which the pin would bounce and hence the pin would not clear the shear line in unison with the other pins. It's still a solid mass with a spring albeit two solid masses and two springs.

You should be able to achieve the same effect by replacing the top pin with a larger pin, perhaps a number 3 or number 4 pin for a Kwikset lock since the Kwickset top pin is just slightly smaller than the number 2 pin. Indeed the two new anti-pick pins from Kwikset are simply different sized spooled top pins. This would make the spring compression in that one position different as well as the mass different so the pin should cross the shear line out of sync from the other pins.

Another idea would be to replace the spring with a hydraulic pin filled with a non-newtonian liquid (corn starch and tapioca comes to mind), this would act like a spring in normal use but the sudden kinetic energy of a bump would cause it to act as a solid pin, only problem is that this would be a problem for locks such as Kwikset where the springs and top pin are retained by a clip, a key bump would likely pop the top off the bible and cause all the springs and pins to pop out but this would be a solution for older locks where the holes in the top did not go all the way through the brass housing requiring you to tediously load the springs and the top pins through the plug hole one by one advancing the plug follower as you went along (a hollow plug follower is needed for this as it allows light to enter the plug hole so you can see). Of course, a strategically placed zip tie would solve this problem for Kwikset locks.

Another idea would be to not let the pins fall all the way through to the level where they would be contacted by the bump key. Master Locks bump stop does this by having one top hole of a larger diameter and a top pin where the bottom portion is of a diameter small enough to enter the plug but the top portion prevents the pin from going too far into the plug. A hobbyist posted on his blog to drill a hole through the side of the plug and stuffing a nail in to prevent a short bottom pin from falling all the way down to where it would be affected by a bump key. A strategically placed dab of super glue or epoxy in to the pin hole of the plug would suffice to keep the bottom pin from falling all the way through (if you mess up the placement of the glue dab and it's something brittle like super glue then it can simply be scraped out by tapping a long pin through but be sure to let it dry throughly before reassembly and testing). I can't see too many people being happy about sticking a nail into the side of their cylinder plug but if you did decide to drill I would suggest drilling and tapping the hole to use a set screw that can be adjusted with an allen key hence allowing you to change the bitting later.

-

jwhou

-

- Posts: 55

- Joined: 14 Apr 2010 21:55

by jwhou » 21 Apr 2010 0:04 by jwhou » 21 Apr 2010 0:04

I found an article entitled "New Anti-Bump Technology From Masterlock by Billy Edwards, CML" where in he described there development process for the Bumpstop product. Apparently they commissioned high speed video of a cutaway lock while being bumped and discovered that it was not the Newton's Cradle effect as is so often hypothesized but rather each pin stack is accelerated at the same rate regardless of mass of the stack and spring compression due to being lifted by the ramp of the triangular portions of the bump keys. The pins don't separate till they are on their way down which I find odd since the bottom pin would then fall by gravity alone whereas the top pin experiences both gravity and the force of the compressed spring. They also mentioned trying telescoping pins and a two part interlocking version to balance the mass but as those should've worked if the Newton's Cradle theory held, the failure of those approaches was what prompted commissioning the high speed video. They also tried a magnetic top pin attracting a steel bottom pin and said that the pins separated as the top pin would set on the shear line on the way down.

This probably explains why Farmer Freak's approach with the second spring separating the top driver pin and the intermediate driver pin which is long enough to prevent the shear between the top driver pin and the intermediate driver pin ever crossing the shear line, worked better than an approach without a secondary spring as transfer of momentum by elastic collisions is not the mechanism by which lock bumping works. This also explains why a pick gun was able to pick the lock albeit after several tries since that does work by impact momentum transfer. It could be that this secondary spring concept not only has a top pin that isn't immediately accelerated with the rest of the pin stack thereby acting as an inertial dampener but the secondary spring and the taller driver pin stack means the driver pin re-enters the plug with greater force hence is not as likely to set. This would also be consistent with reports that a doubled up spring (two springs intertwined) and taller driver pin stacks seem to offer bump resistance.

The article is quite interesting as it talks of how they progressed from a shouldered pin where only the smaller diameter lower portion entered the plug to a tapered design where the imperfection between the shell pin chamber which is intentionally a larger diameter anyways is what floats the pin and finally to an inverse taper as the tapered approach would create deformations in the pin chamber after 20 bumps which made the lock easier to both bump and pick.

Sounds to me like lock bumping simply raises the pin stack till the separation between the top and bottom pins are above the shear line and the top pin simply sets at the slight offset between the chamber alignments caused by the torque applied, basically a mass reverse pick.

As to how this can be used to counter bumping, I'm not sure. Perhaps the driver pin and the bottom pin could be fashioned to snap together if violently pressed together as would be the case when bumped up against the top of the bible but should not be the case in normal usage (of course this would permanently lock the lock against all keys but that's not a bad thing in security ie.: re-lockers) Obviously, how the bottom of the driver pin is shaped to transition across the shear line has already been patented by Masterlock so only variations on the theme would be possible. There seems to be some resistance in the enthusiast community against floating pin concepts citing a vulnerability to advance bumping which means there would be preference for a anti-bump pin stack that pressed down with the same sprung force as the other pins in order to defeat identifying which cylinder had the special pin. Maybe Farmer Freak's approach with the extra sprung mass is about as good as it gets.

It would be interesting to see some high speed footage of the two part sprung driver pin approach to see if the lower intermediate driver pin separates from the top driver pin or if it is indeed the set on the shear line that separates the bottom pin from the driver pins.

-

jwhou

-

- Posts: 55

- Joined: 14 Apr 2010 21:55

Return to The Open Source Lock

Who is online

Users browsing this forum: No registered users and 4 guests

|