|

When it comes down to it there is nothing better than manual tools for your Lock pick Set, whether they be retail, homebrew, macgyver style. DIY'ers look here.

by SomePickNoob » 13 Feb 2015 0:02 by SomePickNoob » 13 Feb 2015 0:02

I used some windshield wiper inserts for these. They need a bit of polishing and a grip, but otherwise they're done. Any improvements that you guys would suggest?  Closeup: http://i.imgur.com/xcAMnZt.jpgEDIT: Changed second picture to a link due to size. GWiens2001

-

SomePickNoob

-

- Posts: 4

- Joined: 10 Feb 2015 23:59

by SomePickNoob » 13 Feb 2015 0:05 by SomePickNoob » 13 Feb 2015 0:05

Welp, that second picture is a bit large.

Right click->open in new window.

-

SomePickNoob

-

- Posts: 4

- Joined: 10 Feb 2015 23:59

by GWiens2001 » 13 Feb 2015 0:12 by GWiens2001 » 13 Feb 2015 0:12

Those look very much like a bunch I made years ago for some lock picking classes at a hackerspace. Yes, a little sanding/polishing and those will work great. Still keep a set of them in my toolbox at work. Also went to Lowe's (a hardware chain for those of you not familiar with them). In their hobby section, found aluminum tubing that, when compressed in a vise on to the picks, made great handles. The teeth in the vise even gave a nice texture to the handles.  Gordon Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by KPick » 13 Feb 2015 0:51 by KPick » 13 Feb 2015 0:51

You know, that's not too bad at all. I remember when I made my first lock pick set and I awe at yours because well, mine were just made out of a pen clip, and a hair pin, which was mediocre at best. My first purchased lock pick set was this one: http://www.southord.com/Lock-Picking-To ... -3010.htmlIt had everything I needed, but due to my novice level, I ruined the shine on them, and now they're great still, but they need a good polishing. How did you make them, and how long did the whole progress take? ◄╕╒═►ĸρîск◄═╕╔══►◄═╕╔══►◄═╕╔══►◄═╕╔══►нттрѕ://шшш.Ιοскpіскiиg1ο1.сοм/

-

KPick

-

- Posts: 623

- Joined: 6 Jun 2013 22:13

- Location: Somewhere Picking A Lock, California

by SomePickNoob » 13 Feb 2015 3:20 by SomePickNoob » 13 Feb 2015 3:20

GWiens2001 wrote:Also went to Lowe's (a hardware chain for those of you not familiar with them). In their hobby section, found aluminum tubing that, when compressed in a vise on to the picks, made great handles. The teeth in the vise even gave a nice texture to the handles.

Hmm, interesting. I have a lot of heatshrink left over from when I used to do R/C as a hobby and was planning to layer that stuff on, but I'll take a look at my local Lowe's when I pick up some sandpaper. KPick wrote:You know, that's not too bad at all. I remember when I made my first lock pick set and I awe at yours because well, mine were just made out of a pen clip, and a hair pin, which was mediocre at best. My first purchased lock pick set was this one: http://www.southord.com/Lock-Picking-To ... -3010.htmlIt had everything I needed, but due to my novice level, I ruined the shine on them, and now they're great still, but they need a good polishing. How did you make them, and how long did the whole progress take?

I actually picked up a 14 piece set, the SouthOrd MPXS-14 on MassDrop. I paid about 30 bucks for the kit after shipping and taxes, but they probably won't be here for another month or so - hence the homemade picks. Everything was cold-bent(I don't have a torch). I bent the picks along their width with two pliers(a little bit tricky but still doable). I then cut off the excess with a dremel, and used a grinding tool on the dremel to shape and smooth out the picks. I don't have a vise to hold pick, so I dug around and found a small bar clamp and a small C-Clamp, which worked surprisingly well. Total time for all 3 pieces was about 2 hours.

-

SomePickNoob

-

- Posts: 4

- Joined: 10 Feb 2015 23:59

by GWiens2001 » 13 Feb 2015 7:45 by GWiens2001 » 13 Feb 2015 7:45

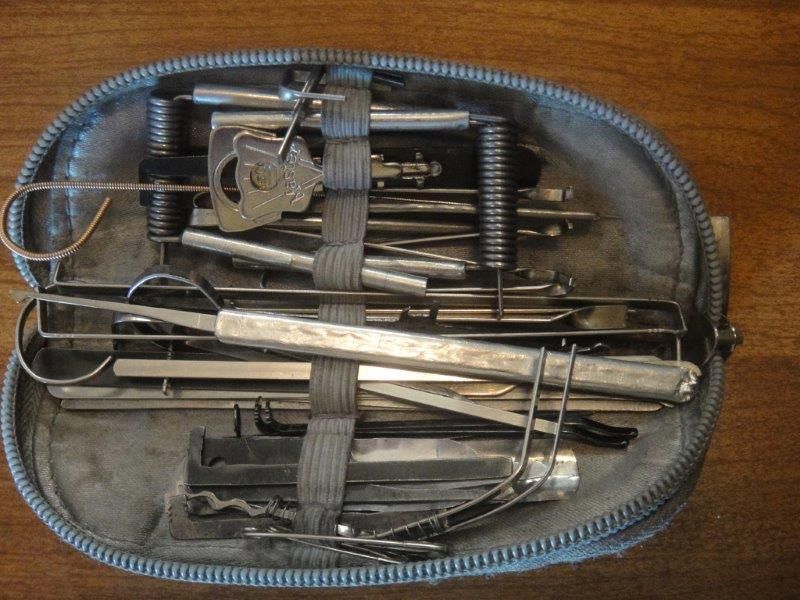

The pick on top in the center was the first one I made as described above. Used the flat sides of the vise, so it did not leave the cool pattern on the handle. But you can get the idea.  Gordon Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by smokingman » 13 Feb 2015 9:03 by smokingman » 13 Feb 2015 9:03

Kudos to both of you! I love seeing home made tools, they are the best. I only have a couple of store bought sets but have many that I made. There is nothing like customising your tools.  What is the best way to educate the masses? ... " A television in every home."

What is the best way to control the masses? ... " A television in every room."

From "Charlie" AKA " Flowers for Algernon"

-

smokingman

-

- Posts: 337

- Joined: 15 May 2013 12:09

by SomePickNoob » 15 Feb 2015 1:55 by SomePickNoob » 15 Feb 2015 1:55

I just got my practice lock from eBay today, and I found out that my unfinished picks were a little bit on the big side. I went to Home Depot and found some 1500 grit sandpaper. Unfortunately, I was in a hurry so I didn't get to check out the aluminum piping, and I also don't have a good vise to compress the tubing with  . I took another two hours to work on my picks. I actually made another one to see how it'd work if I removed material before bending the hook, and that worked out really well. I shaved off some material on one of the picks I made before, then gave my 2 properly sized picks a good sanding. Laziness made me leave the third pick unmodified - I'll probably shave & sand it another day. Original Link: http://i.imgur.com/v2tET8j.jpg The grips are creates with two layers of heatshrink. Overall, they seem to work! I pinned up the practice lock with 2 pins and have been able to open it. Now, it's just time to practice.

-

SomePickNoob

-

- Posts: 4

- Joined: 10 Feb 2015 23:59

by sentientsentinel » 17 Feb 2015 20:11 by sentientsentinel » 17 Feb 2015 20:11

Looks nice and you now have a skill that will last forever and no one can take it away from you.

-

sentientsentinel

-

- Posts: 78

- Joined: 21 Jan 2015 16:35

by deolslyfox » 19 Feb 2015 19:27 by deolslyfox » 19 Feb 2015 19:27

Lookin' pretty good !! You should polish out all those rough edges. I'd suggest not making the hook tips quite so pointed. Its easier to keep the pick tip on the pin when lifting / levering if the pick tip is flat.

How wide should a pick tip be ?? Just a tad smaller than the pins you're working with. But, to get started, anything between .060" and .070" should pretty much do a good job for you. Thickness is another issue. Thicker picks (.030", .025") are OK for most applications, but once you get into smaller keyways, paracentrics, euro-style locks, you are going to need thinner (.015") picks to work around that warding.

If you get into some really tight keyways, small pins, etc, you can always make a home-brew to address that issue. Or, wait until your favorite pick manufacturer has a clearance and buy a couple of spares. File the shaft / tip down to the size you need and you'll have a pick that matches your set as well as your needs.

When you get the "pick making process" down pat, try working with some high carbon or stainless steel feeler gauge stock. It makes a strong, long-lasting and good-looking pick. Stainless is harder to work with, but you can bring it down to a really small diameter while retaining plenty of strength to successfully work in 6 and 7 pin paracentric keyways. You can find 12" feeler guage stock at "Eastern Industries" .... They also have coils if you decide to go into high rate production !!

Keep up the good work !!

-

deolslyfox

-

- Posts: 128

- Joined: 15 Feb 2015 17:01

Return to Lock Picks

Who is online

Users browsing this forum: No registered users and 7 guests

|