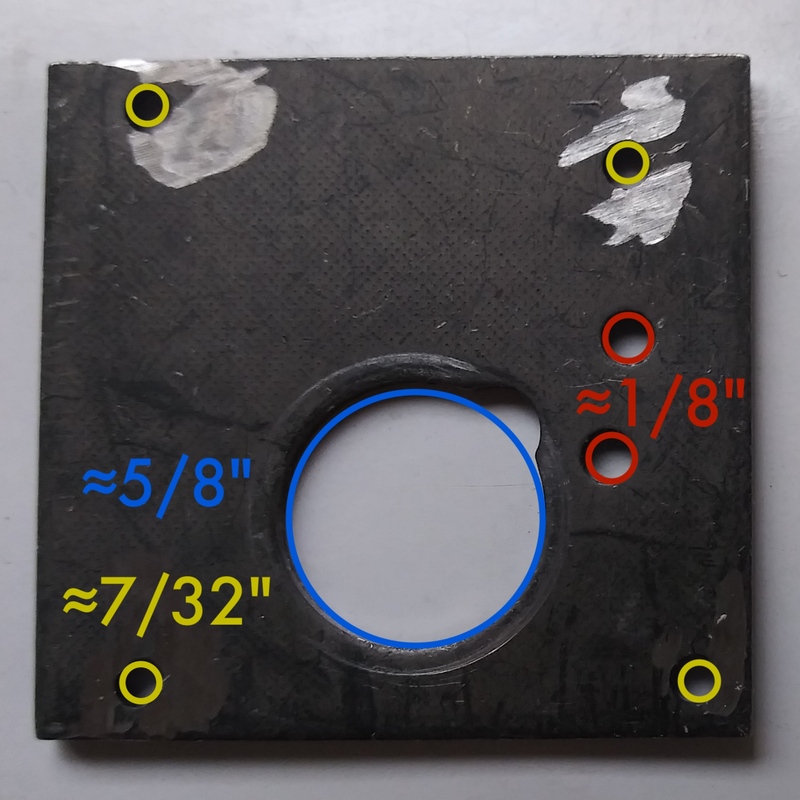

If you want to try at home: the hard plate was approximately 0.0875" thick (could call it 2mm, just don't go bigger) with length 1 11/16" and width 1 9/16". The four holes in the corners had diameter ~7/32", the two located middle of the right side had diameter ~1/8", and the center hole (not including the little cutout) had diameter ~5/8", probably call it 9/16" to be safe, 'cause you can always make it bigger.

To create the center opening without the acrylic cracking, I drilled small 7/32" holes just inside the perimeter of the shape, then larger 9/32" holes in the middle to fit a coping saw blade. Used the coping saw to work around the edges, removing the center material, then filed down the peaks around the perimeter with needle files. Finally a dremel with carbide bit to trace the perimeter, widening the opening to size. Took me about an hour, re-starting once, so not too onerous a project if you have the tools.