FarmerFreak wrote:Ok, so the lock has been turned a 180 degrees and a key pin fell out.

What you should do now is check to make sure that only one key pin fell out. You do this by looking into the cylinder and see how many pins have a rounded bottom or a flat bottom. The ones that are rounder are correct key pins, the ones that are flat on the bottom are the driver pins.

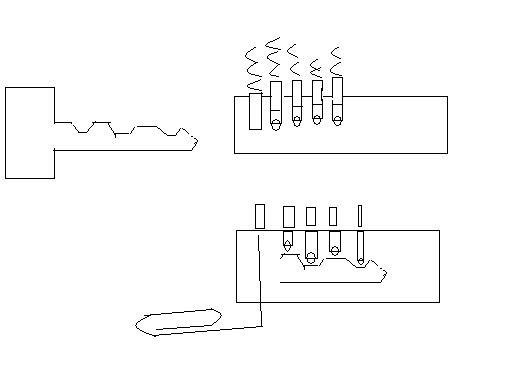

You will need to lift the driver pins up over the shear line. If only one of the key pins isn't in the lock and you are willing to sacrifice a key you can do this nifty little trick.

Disclaimer: this was done in about a minute, nothing is to scale.

Once you know for certain which pin chamber is missing the key pin. You cut that cut/space off of the key, put the key into the lock at it's correct position. And usually a small paperclip can be inserted through the hole in the bottom of the lock slip past the broaching and lift the driver pin up and over the shear line. After turning the lock about 2-4 degrees or so you will need to take the paper clip back out of the lock to turn it farther.

If a paperclip won't go in past the broaching then you can try to bend the paper clip into a hook pick type of shape and work on overlifting the pin from the front of the lock through the keyway.

Either way make sure that you know for certain which pin(s) are missing before getting too far.(cutting up the key)

Yeah thats what I noticed that the one near the front of the lock was flat so thats the only one im missing so I guess I could sacrifice a key. Ill try it later when i have time