The older best IC cores had holes in the control sleeve (the thing you have to turn with the plug to be able to remove the core). There is a tension wrench that looks like a comb that can be inserted into these holes to turn the control sleeve. However, the newer cores don't have these holes.

If others have had luck picking these I'm impressed. With 4 pin stacks that can operate either the control sleeve or plug, that gives you 16 possible combinations. One of which will open the lock and one that will remove the core. But since we all know that there are machining imperfections, the pins will have a preference to set in one particualr position. If it's not the position you need them in, you might pick the lock a hundred or more times before you get lucky and have them end up at the right shear line.

About a week ago, I tried something. It worked.

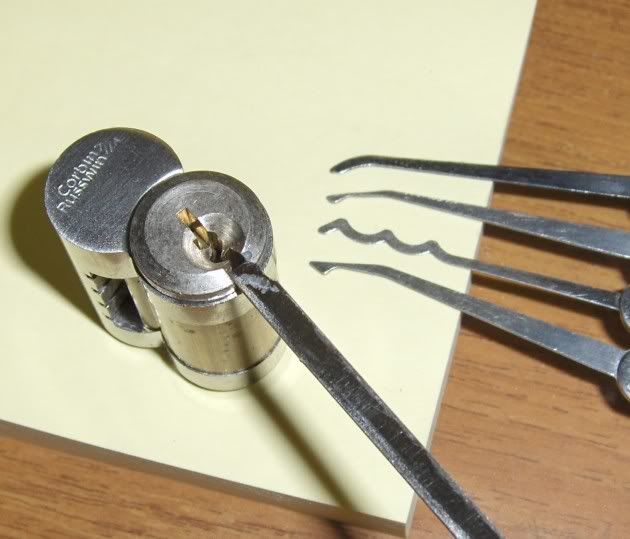

I had a corbin IC core, not a Best but the theory is the same. Here's the core.

To pick this, I simply glued the tension wrench to the control sleeve using some 2 part epoxy. I tried super glue but it wouldn't hold.

It worked, I was able to quickly pick the lock to the control shear line. Although I picked this in my hand, I could have pulled the core once the sidebar was pulled in.

Somebody asked about this ruining the lock. I used a tiny drop of the epoxy and after I pulled the wrench, it only took a couple of scrapes with the pick to get all the epoxy out.

One mistake I made was that I put the drop of epoxy on the tip of the tensino wrench and glued the pick to the control sleeve and not the plug. Once I had picked the control sleeve, I had to insert a second tension wrench to pick pins 1 and 6 to turn the plug. I'm not sure how I'd handle this next time but I'd do something a little different.