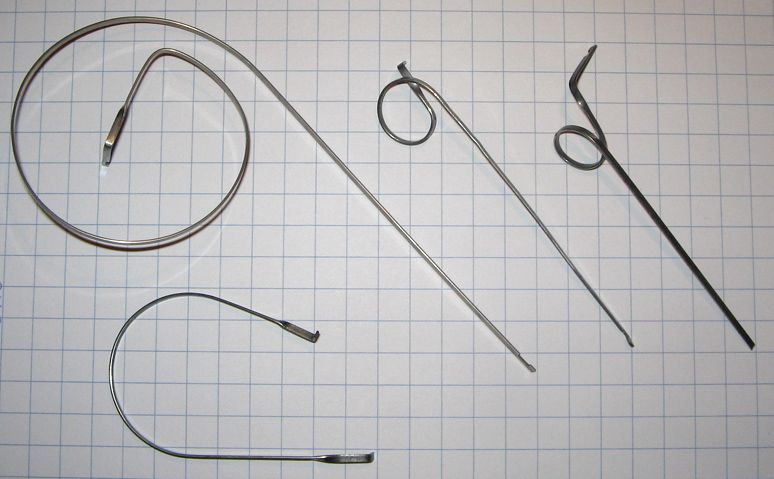

TOOLS:

Vice grips - 2 smaller size pairs, but the more sizes the better

Spring - tightly coiled or loose coil, your choice.

Utility cutters - Essentially hardened wire cutters, or the cutter on a pair of vice grips could work.

Needle files - I used a knife file, but you could get away with a triangle.

Wiper insert, or street sweeper bristle - I recommend the widest wiper insert you have, but either will work.

OPTIONAL:

*Heat shrink - electrical tape or equivalent will work

*Grip Gloves - you'll want them

*Dremel tool - entirely optional

For clarities sake:

I hope needle files is self explanitory.

First off you will need to cut two pieces of wiper insert 1 1\2 and 2 1\2 inches long. The extra length is for redundancy and we will be taking off excess later.

To do this you can use a dremel tool and a cutting disk, or you can use your two pair of vise grips to shear the insert cleanly. I use two pair tightly clamped and very close together like this...

Now twist and the it should shear nicely. You can also grip with one pair and tightly bend up, and then down to shear it off. This is sloppier though and will require you to file off more sharp, bent edge.

Now that you have you two pieces you will want to start cutting the alternating nothces into the ends. Start as close to the edge as you want the size of the teeth on the two pieces. Remember that this is the part we will be wrapping the spring around, so make sure it will fit in the notches nicely.

Ideally you want to make the cuts alternating so that one cut is in between the cuts on the opposite side. Do this on both pieces. I recommend if you have a slimmer wiper or a sweeper bristle you do less notches than pictured here. 3 to 3 or even 2 to 3. The thicker the spring the more stress the insert is going to have to withstand during wrapping.

Now you want to take your spring and cut it to the desired length. 5 or 6 coils seems just about perfect, but depending on the spring strength and the desired effect you can use more or less. Remeber we are going to be uncoiling the spring, so you will want to cut 2 or 3 more coils on either side than you will want on the finished wrench. If you are trying to use needle nose pliers for this part, best of luck. It can be done.

Now you are going to want to straighten the spring. To do this take your smaller vice grips and clamp them on the spring as near to the tip as possible while still gripping some of the curve. You want to use the leverage of the vice grips to straighten the spring as you close them. Don't make them too tight or you will strain yourself and unnecessarily mar the spring. As you straighten the spring you can bend it into a straighter shaper using your pliers, this is where having a larger pair of vice grips comes in handy as you can clamp the uncoiled, but still very curved spring, and further straighten it with little effort. Otherwise you will have to use your two pairs of smaller ones in a joint effort to accomplish this task. It is not necessary it be 100% straight as we will be recoiling it around the handle and tip piece, but it should be straight enough as to not get in the way. You want both ends to be on the same side of the spring.

Now from the coil walk the notched blank end over end the desired length of straightened spring. 3 to 3 notches is 7 1/2 widths, 3 to 4 is 8 1/2, 2 to 3 is 6 1/2. You want enough straightened spring to start, wrap around once for each notch and end with enough left for a 90 degree bend at the end with left 1/2 width. To a large degree this is eyeballing it. It could be done reverse to possibly avoid excess straight spring, but then you risk a wrench that is tail high, low, perhaps even same sided and you will have little room to straighten more spring.

Roll up your sleeves men, because this is the hard part. Grip the approximated end of the spring tightly with one pair of pliers just below the first notch and begin to recoil the spring tightly around the blank. You can use another pair of pliers if you have to, but be careful to NOT put to much rotational stress on the blank itself. If you are using an especially strong spring you may need 3 pliers. 1 to grip the spring to the blank at the starting point, 1 for grip so you can tightly coil, and 1 to grip close to the loop being coiled to prevent excessive rotation. It seem like you would have to have 3 hands for this, but the bench will in effect hold the first pair in position for you as you coil.