Background

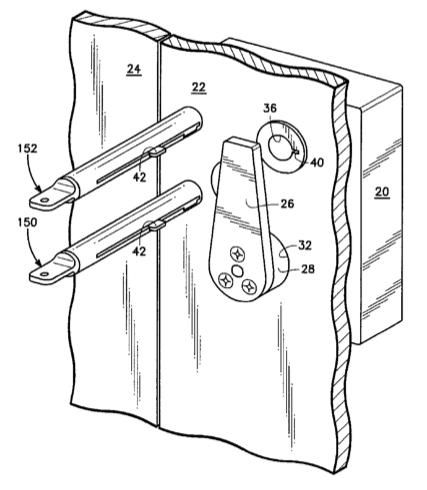

The US Department of Defence is responsible for setting standards for military locks, safes, seals and containers. Prior to 1994, the DoD Lock program relied on using high-security padlocks and hasps (e.g., S&G 833C, Hi-Shear) to secure the entrances to munitions magazines, such as the one pictured below:

The DoD Lock programme is currently managed by the Naval Facilities Engineering Service Centre (NFESC). In 1994 the DoD determined that the risk of attacks on magazines housing sensitive nuclear and chemical weapons were sufficiently high that an alternative to padlocks needed to be developed.

ILD: Internal Locking Device

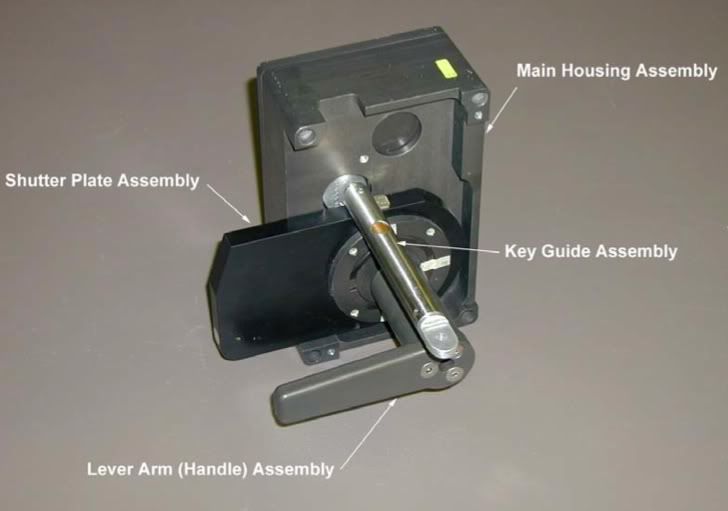

The ILD (Internal Locking Device) is a custom-developed deadbolt, designed by Naval Facilities Engineering, that is now replacing the older padlocks and high-security hasps. It utilizes either one or two standard Medeco mortice cylinders, and a custom “sabot†key guide assembly – similar to a number of the older German safe locks, like the Panzer Vierbart. The idea with the key design is that the lock body is secured deep inside the lock, which protects it from physical attack, while also making it much more difficult for potential attackers to access the keyway(s).

The following photo shows a typical ILD installation on a sliding blast-proof magazine door:

The DoD describes a variety of configurations:

- The ILD is locking device that operates boltwork systems designed for specific magazine door applications. The ILD and boltwork function as a complete locking system for sliding and swinging magazine doors. The ILD can be modified for use with electronic access control, hard-wired intrusion detection systems (IDS), and wireless IDS. The exterior dimensions of the ILD unit are 8 X 5 X 3 inches and weighs less than 10 pounds.

- Source: Unified Facilities Criteria (UFC) 4-420-10

In addition to the requirement that it meet a significant host of environmental operating requirements (e.g., freezing, high temperatures, sand, vibration, etc), the ILD was designed to withstand a wide range of physical attacks:

- 15 minutes of surreptitious neutralization attempts by picking, shimming, impressioning, and bypassing methods.

- Forced entry for 10 minutes using medium threat including unlimited hand- and battery-powered tools; limited thermal tools.

- Resists being pulled open with a 12,000-lb force.

- Source: MIL-P-43607G, DOD 5100.76-M (Ref 11) Section 3.0, NCEL OR# 098-09-88, MIL-P-43607G.

Patent 6,675,616 was awarded in January 2004:

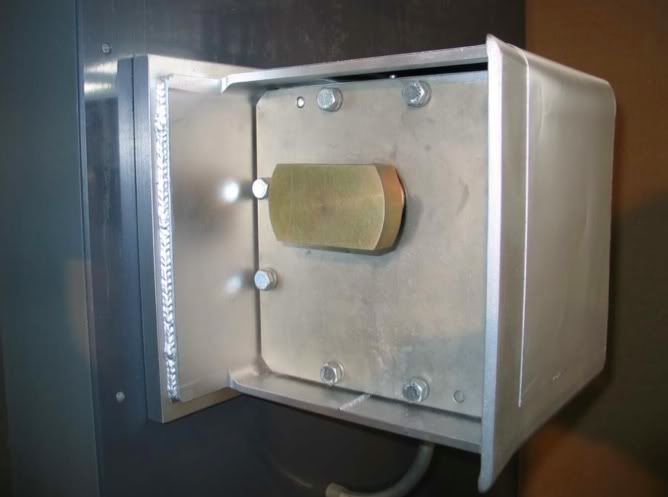

The ILD uses a simple deadlocking arrangement, using a pivoting locking bolt and a matching receiver hole. These photos show a side-view of the ILD and the rotating locking bolt, and the matching receiver plate:

Disassembly

Accessing the locking mechanism requires the removal of eight bolts, so that the rear locking plate can be lifted off:

and then the four mounting bolts which holds the ILD's locking mechanism in place:

Finally, the rear plate of the actual lock housing is secured by four bolts:

Locking Bars

The rotation of the bolt is restricted by a pair of locking bars. When either bar is in the furthest-right position (as pictured) it locks the bolt, preventing it from turning:

Each locking bar is controlled by a separate mortise cylinder; its tailpiece moves the aluminum cup which slides the bar:

Locking Cylinders

Depending on the access requirements of the facility, the ILD can be configured in either a single- or a dual-keyholder configuration. This image shows a single-keyholder configuration, with a single Medeco mortise cylinder:

Pictured here is a dual-keyholder configuration, with two Medeco mortise cylinders; it requires two people to be present to open it:

The mortise cylinders are held in a simple (non-threaded) carrier, and can be quickly swapped out in the event of a lost key (or when a construction cylinder needs to be replaced with the final operating cylinder):

Key Guide Assembly

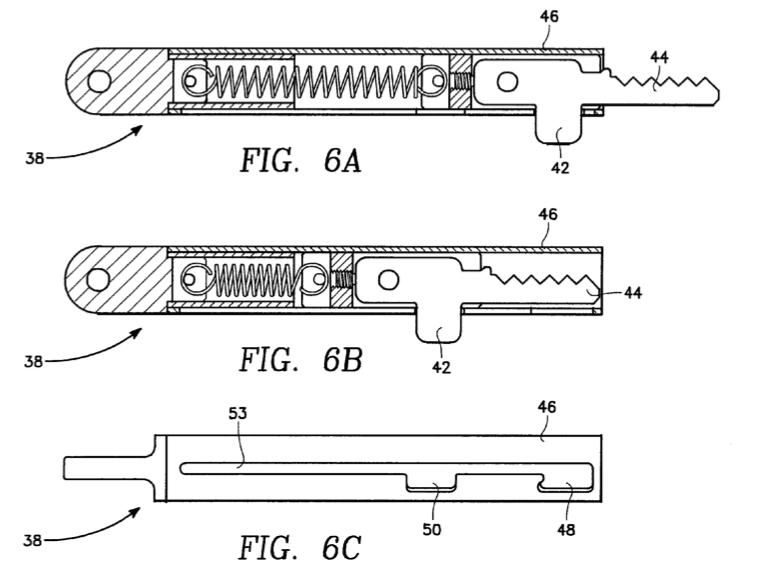

Because the locking cylinders are located several inches inside the body of the ILD, the keys are inserted inside a custom-designed "sabot" key guide assembly:

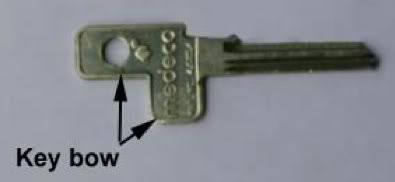

The cylinders use a restricted-keyway Medeco key blank with a custom bow:

The construction keys, used during installation, are mounted on a simple aluminum rod:

In order to limit the ability for a potential attacker to decode the key biting from a photograph the actual operating keys are held in a spring-loaded sabot that keeps them hidden until just before they are inserted into the lock. (They keys are held into the sabot with a T-30 tamper-resistant bolt, in an effort to prevent someone from removing or swapping out the key.)

This is clearly not a lock that's going to appear on eBay anytime soon -- but it's nonetheless interesting to see how the DoD is using retail locks and some custom engineering to create a new high-security solution.