Take a look at these keys:

How about off the key ring…

What do they have in common? Give up? They all open this lock:

Not only that, but the lock is not master keyed. That is correct. The keys all have the same bitting!

How can this be if they all look so different? It has to do with how the pins interact with the key.

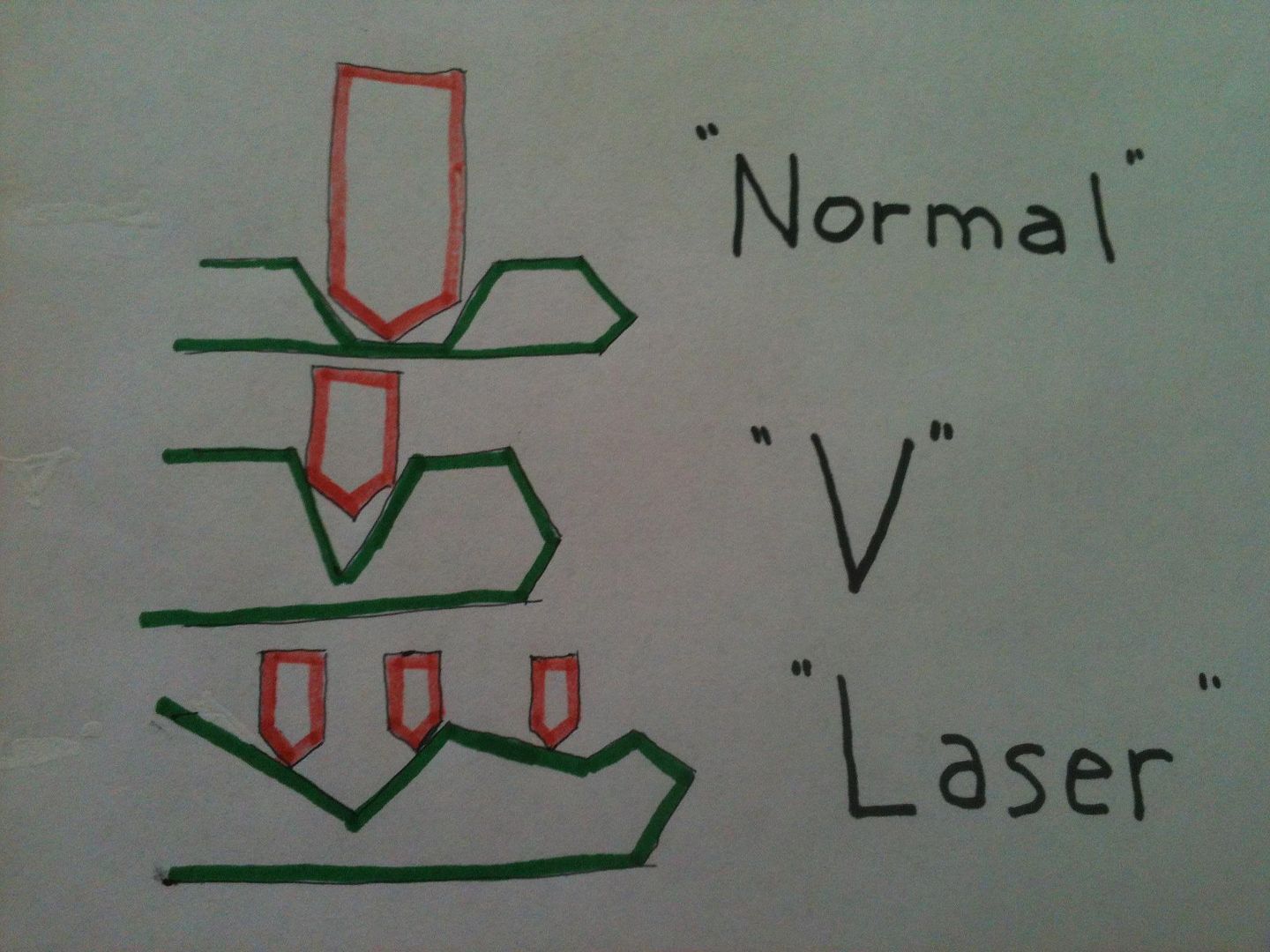

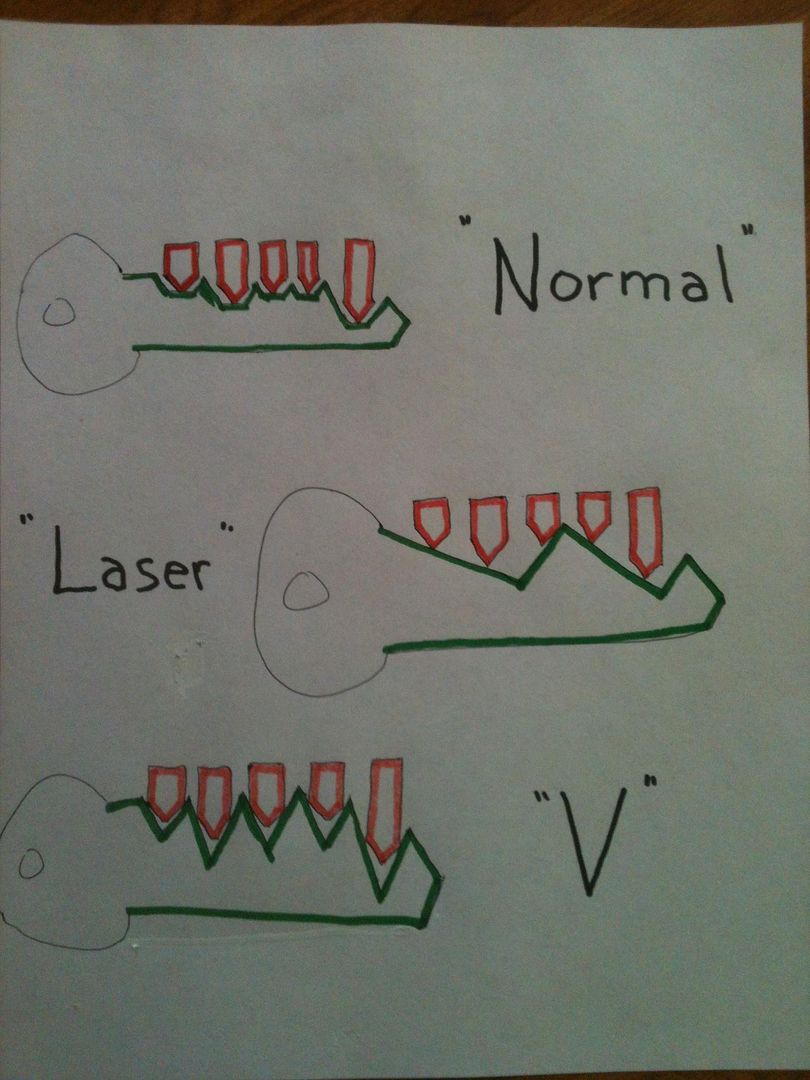

On a “normal" key, the tip of the key pin rests at the center of the flat spot at each bitting, so the tip of the key pin is used to set the pin at the correct height.

In a “V” cut, the edges of the pin are held, not the tip of the key pin. The edges of the ramp and pins are what is used to set the pin height.

On a “Laser” key (Not to be confused with a laser track key), the ramps can use either the tip of the key pins or the edges of the key pin to set the pins at the correct height.

So you can see that on a “normal" key pin, the edges of the key pin are not used to set bitting height, but they are on a “V”, while on a “Laser” key, either can be used.

Now in this highly accurate drawing (yeah, right

Used a key machine and depth keys to cut the “Normal” key, but hand filed each of the other two types of keys.

Why have different ways of cutting the keys? A couple reasons. The key machine cut key (Actually the last of the three I made) is how you expect the key to look. So the same keys, side by side, will look like they are for different locks. Also, the “Laser” key, with fewer peaks, would cause less pin wear.

The “V” key (made first, a year or so ago), especially used with a 6 pin blank instead of a 5 pin blank, can (and was) used so the key did not look like someone would expect… it was the same key, but disguised. (Someone wanted me to have a key, but not have others know that I had it, even if they looked at my key ring). So this is a bit of a way to ‘hide’ the bitting of the key.

The “Laser” key is specifically made to make visual decoding especially difficult. This is extra-true with this key, since I specially made it so none of the pins align with either the peaks or the valleys of the cuts.

All three keys work in the lock as well as a factory cut key - in fact, the “Laser” key works even more smoothly for insertion and extraction from the lock.

You can make a “Laser” key for pretty much any bitting, but will probably need to cut/file it by hand unless you have access to a special key cutting machine. When I make them, my goal is to make all the angles different, and have them being different lengths, to make decoding harder.

The American 5260 padlock pictured is no longer in use where it came from, so not worried about posting actual pictures of the bitting. It was given to me when the person sold their shed without the lock.

So next time you want to make a key, there is your challenge: make your key a bit differently… if you can make it work properly. Just be sure that the key and lock works smoothly and reliably before you try using it on a lock you depend on.

Have fun!!!

Gordon