|

Having read the FAQ's you are still unfulfilled and seek more enlightenment, so post your general lock picking questions here.

Forum rules

Do not post safe related questions in this sub forum! Post them in This Old Safe

The sub forum you are currently in is for asking Beginner Hobby Lock Picking questions only.

by skold » 22 Feb 2005 3:40 by skold » 22 Feb 2005 3:40

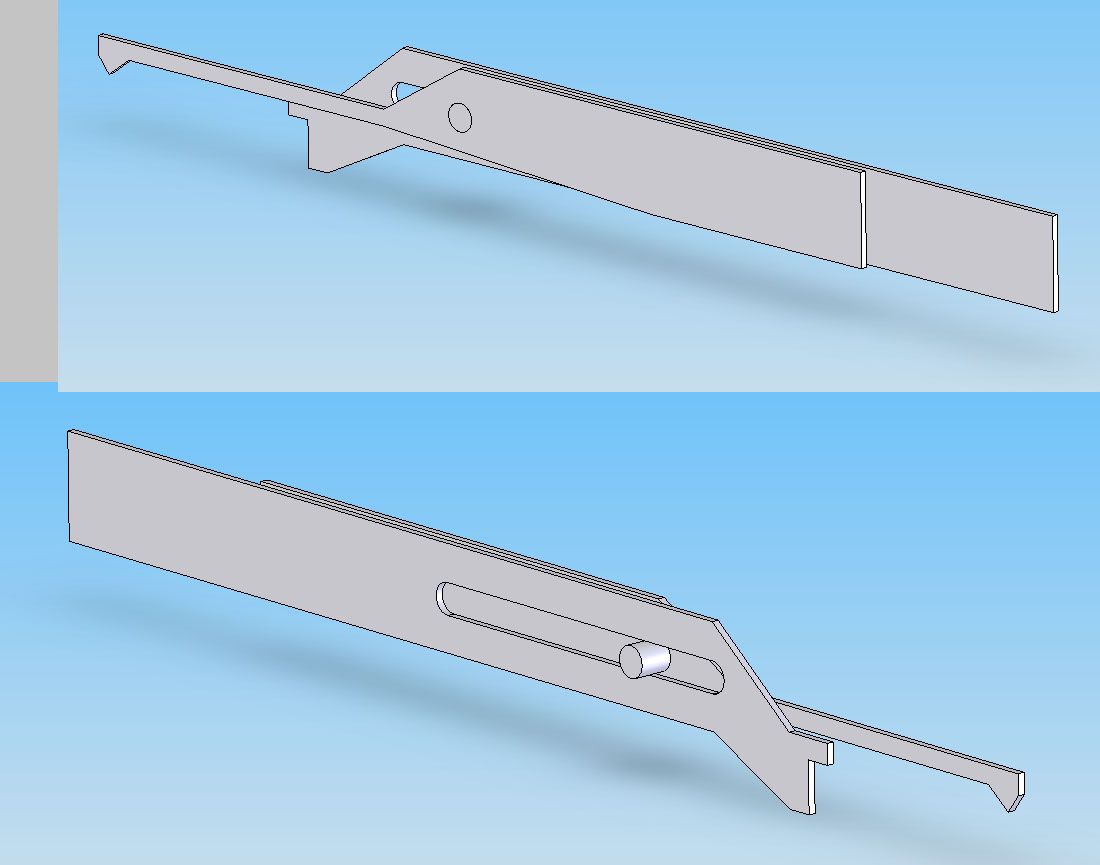

http://img.photobucket.com/albums/v329/skold/img003.bmp

Sorry it’s the wrong way up, haven’t got my scanner working to its full potential as of yet.

My basic Idea is the have a tension/stabilizer bar and have the reader have the ability to go the every pin height and lock depth in a Lockwood lock., the depths can be used as a picking guide, but it generally just used to determine the pin depth when the cylinder is turned/picked.

I am currently working in a better looking pic/drawing in Qikdraw, but the drawing seen above is just so we all have a general Idea what I am talking about.

I would like some help to refine my ideas, so that I can make this little project of mine work.

Any comments, suggestions, flames. Anything at all?

Cheers,

Skold

-

skold

-

- Posts: 2250

- Joined: 24 Feb 2004 3:59

- Location: Australia

by Exodus5000 » 22 Feb 2005 8:44 by Exodus5000 » 22 Feb 2005 8:44

Perfect Skold, that's exactly the kind of idea I was thinking, plus your version looks much better, and I like the idea of having a pin depth gauge right on the slide rather than just a ruler. Perhaps a modified steel ruler with the various pin sizes etched into it would make for easy reading. Now building and/or modifying this device should prove interesting.

[deadlink]http://img441.imageshack.us/img441/6973/exodus5000ac5.jpg

-

Exodus5000

-

- Posts: 952

- Joined: 6 Apr 2004 23:57

- Location: Sturgeon Bay, Wisconsin, USA

by Peaky » 22 Feb 2005 12:28 by Peaky » 22 Feb 2005 12:28

As we are all submitting our fag packet designs heres a simpler/easier idea i had whilst reading this interesting thread,

You could use a scissor system whereby the opposite ends of the feeler picks directally show on a scale,

You would have to measure each pin individually but could use it for any keyway height,

You could have just a scale which you would referance against a list of the differant pin heights depending on lock or you could have a couple of these and have a high keyway against a low keyway so having 2 differant types of lock covered (i have used ERA and Yale as an example on the sketch),

You could use your dial vernier instead of the scale if you wish.

http://tinypic.com/view.html?pic=1t0xat

-

Peaky

-

- Posts: 459

- Joined: 24 Oct 2004 10:43

- Location: Derbyshire, UK

by kennylt » 22 Feb 2005 14:16 by kennylt » 22 Feb 2005 14:16

wow thats a good idea - easy and effective

-

kennylt

-

- Posts: 21

- Joined: 6 Sep 2004 11:55

by digital_blue » 22 Feb 2005 15:29 by digital_blue » 22 Feb 2005 15:29

Peaky, way to go. That's the closest I've seen yet to something that I think would be genuinely practical! Great job!

db

-

digital_blue

- Admin Emeritus

-

- Posts: 9974

- Joined: 6 Jan 2005 15:16

- Location: Manitoba

-

by macaba » 22 Feb 2005 17:28 by macaba » 22 Feb 2005 17:28

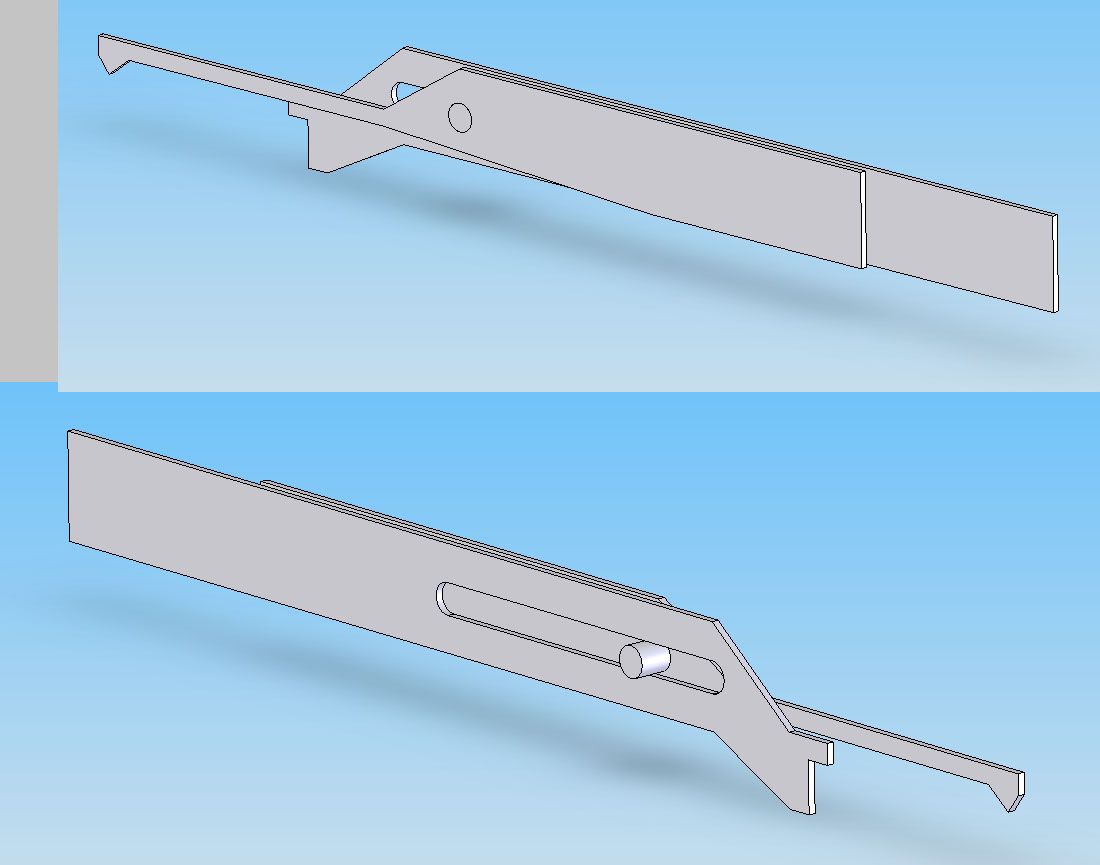

Heres my attempt at interpreting the design

To maintain tension, you simply wrap an elastic band around it, and to have a system of measurement, there would be some kind of markings. The rest is obvious.

-

macaba

-

- Posts: 231

- Joined: 23 Nov 2003 5:40

- Location: Uk

by Peaky » 23 Feb 2005 7:05 by Peaky » 23 Feb 2005 7:05

Thanks everyone, sometimes its the quick 1 min idea off the top of your head thats the best,

I will have a dabble with some wiper blades later and see if i can knock one up, at least we will have an idea of development then,

Like your idea Macaba, have a go at making yours and then we can compare and find the limitations and strengths of both then come up with an ultimate one.

-

Peaky

-

- Posts: 459

- Joined: 24 Oct 2004 10:43

- Location: Derbyshire, UK

by Ives » 23 Feb 2005 7:44 by Ives » 23 Feb 2005 7:44

Hey, can't you guys put a copyright on that design, this looks really good and working!

-

Ives

-

- Posts: 22

- Joined: 30 Jan 2005 13:17

- Location: Merksplas, belgium

-

by raimundo » 23 Feb 2005 10:36 by raimundo » 23 Feb 2005 10:36

very clean and simple drawing macaba, but can I suggest that it can be more stable to hold it straight if the part of the chassis that goes into the key way be designed to go into the part of the keyway where the uncut edge of the key goes, the longer length of the part that can go in there will make holding it straight much more positive. Yes, I understand that you are doing this with the part that addresses the face of the plug, as well as the part that goes in. I'm just suggesting a modification.

Wake up and smell the Kafka!!!

-

raimundo

-

- Posts: 7130

- Joined: 21 Apr 2004 9:02

- Location: Minnneapolis

by toomush2drink » 23 Feb 2005 11:12 by toomush2drink » 23 Feb 2005 11:12

I love this idea but see one problem at the moment this will only work on locks with not much in the way of warding. I suppose it depends on which part of the keyway the bottom of the tool is inserted.

Great idea though

-

toomush2drink

-

- Posts: 1966

- Joined: 26 Mar 2004 15:56

- Location: UK london

by macaba » 23 Feb 2005 12:31 by macaba » 23 Feb 2005 12:31

raimundo wrote:very clean and simple drawing macaba, but can I suggest that it can be more stable to hold it straight if the part of the chassis that goes into the key way be designed to go into the part of the keyway where the uncut edge of the key goes, the longer length of the part that can go in there will make holding it straight much more positive. Yes, I understand that you are doing this with the part that addresses the face of the plug, as well as the part that goes in. I'm just suggesting a modification.

The exact reason why i didn't do this is because the keyway of this cheap euro lock i have here is very rescrictive. In order to get something at the top of the keyway, i would have to incorporate a bend into the design, which would also mean that it may not work on certain keyways and different size locks. the advantage with the way i have drawn, is that it always measures from the very bottom of the keyway, and an uncut key is at the bottom of the keyway, so it makes it so that on any size lock, its universal, as its measuring from a point that is universal on any uncut key.

-

macaba

-

- Posts: 231

- Joined: 23 Nov 2003 5:40

- Location: Uk

by macaba » 23 Feb 2005 12:35 by macaba » 23 Feb 2005 12:35

toomush2drink wrote:I love this idea but see one problem at the moment this will only work on locks with not much in the way of warding. I suppose it depends on which part of the keyway the bottom of the tool is inserted. Great idea though

I am assuming that most pin tumblers have an length between the face of the lock, and the first pin, which is where the sticking out bit goes in. I also put the pick part on the left surface, as thats the bestest arrangment for the wards on this euro lock i have here, as i've attempted to depict below.

||||||||....|||

||||||||....|||

||||||||||...||

||||||||||||||

Mac

-

macaba

-

- Posts: 231

- Joined: 23 Nov 2003 5:40

- Location: Uk

by jimmysmith » 15 Jan 2007 0:22 by jimmysmith » 15 Jan 2007 0:22

what about if you got a peace of clay, smashed the key into it leaving an inpression of the key, then filled the mold with some type of hardening material, let it dry. pull the mold apart, and put it on the duplication machine and cut a key from it..... think it will work? I am going to try, what type of hardening material do you guys think i should try? has any one ever tryed this and if so...how well did it work.

thanks

-

jimmysmith

-

- Posts: 283

- Joined: 13 Jan 2007 20:28

- Location: Portland Oregon, USA

-

by Deathadder » 15 Jan 2007 0:36 by Deathadder » 15 Jan 2007 0:36

xodishox wrote:wow, nice thinking, check your grammer btw.

lol, sorry, but I thought it was funny that you spelled grammar wrong  It's ok guys, i have a really bad attention sp-wow look, a beach!

-

Deathadder

-

- Posts: 546

- Joined: 22 May 2006 13:05

- Location: Ocala, Florida

by jimmysmith » 15 Jan 2007 14:44 by jimmysmith » 15 Jan 2007 14:44

No one thought that was do-able?

-

jimmysmith

-

- Posts: 283

- Joined: 13 Jan 2007 20:28

- Location: Portland Oregon, USA

-

Return to Got Questions? - Ask Beginner Hobby Lockpicking Questions Here

Who is online

Users browsing this forum: No registered users and 3 guests

|