|

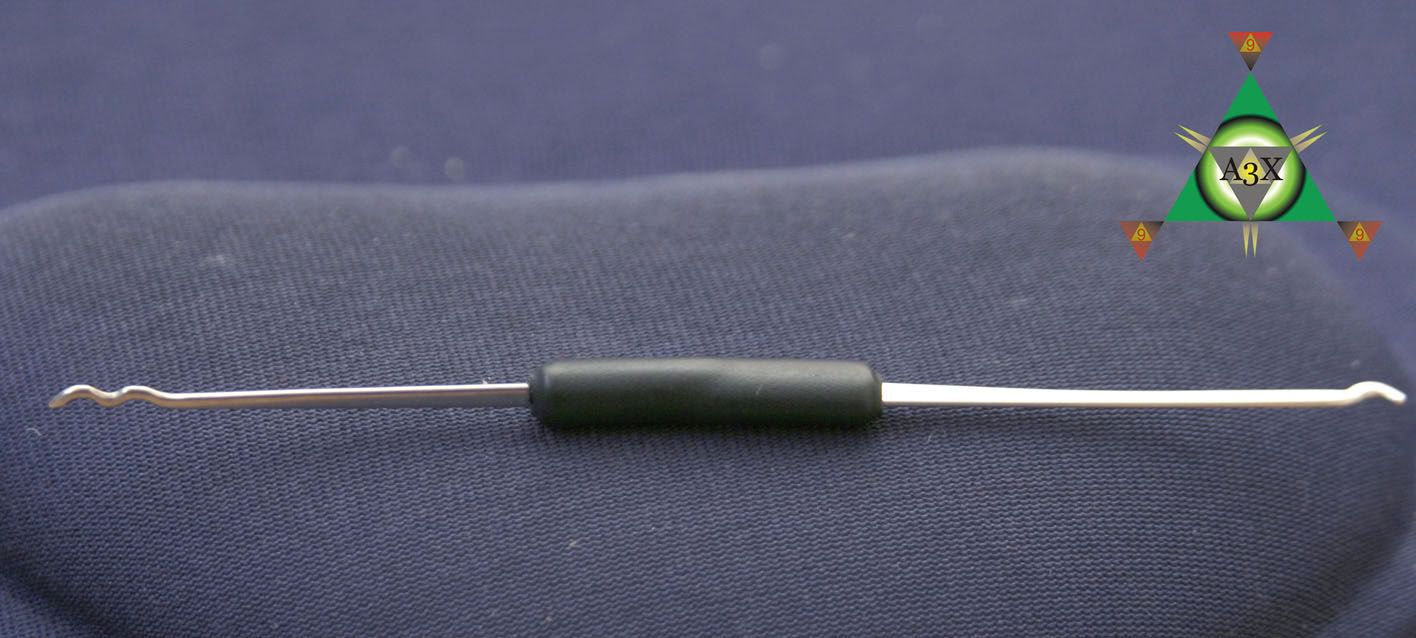

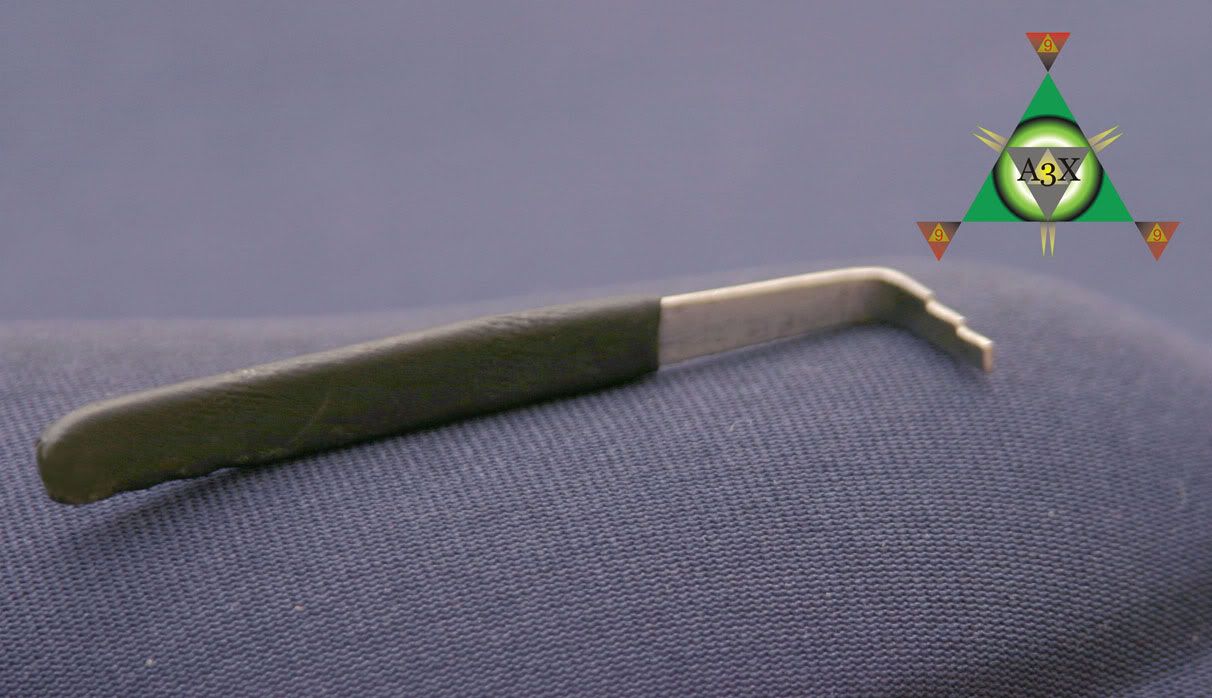

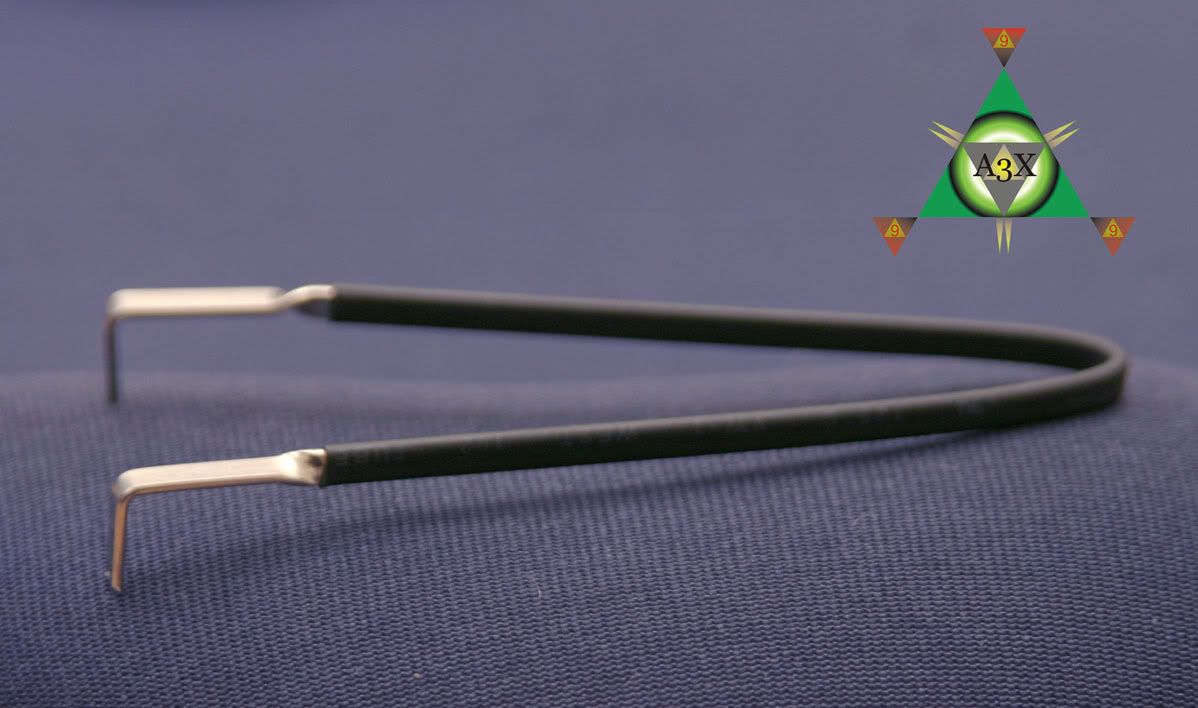

When it comes down to it there is nothing better than manual tools for your Lock pick Set, whether they be retail, homebrew, macgyver style. DIY'ers look here.

by atrix » 12 May 2006 4:18 by atrix » 12 May 2006 4:18

-

atrix

-

- Posts: 66

- Joined: 22 Sep 2005 3:43

- Location: Ukraine

by Fah_Cue » 12 May 2006 5:57 by Fah_Cue » 12 May 2006 5:57

wat material did u use? wiper blades?

-

Fah_Cue

-

- Posts: 305

- Joined: 30 Aug 2005 5:59

- Location: Sydney, Australia

by Fah_Cue » 12 May 2006 5:58 by Fah_Cue » 12 May 2006 5:58

forgot to mention that they look great

-

Fah_Cue

-

- Posts: 305

- Joined: 30 Aug 2005 5:59

- Location: Sydney, Australia

by mattc » 12 May 2006 6:25 by mattc » 12 May 2006 6:25

Nice, but what are the curved picks made from?

[One day, I'm going to apply for the Advanced section, just to see if I get accepted....]

-

mattc

-

- Posts: 249

- Joined: 11 Apr 2004 14:50

- Location: UK

by Jason13 » 12 May 2006 6:32 by Jason13 » 12 May 2006 6:32

I think thats just bending wiper blades with pilers which would be hard and nice work!

-

Jason13

-

- Posts: 1475

- Joined: 9 Nov 2005 11:37

- Location: UK

-

by mattc » 12 May 2006 6:36 by mattc » 12 May 2006 6:36

I was thinking bra underwiring  [One day, I'm going to apply for the Advanced section, just to see if I get accepted....]

-

mattc

-

- Posts: 249

- Joined: 11 Apr 2004 14:50

- Location: UK

by Jason13 » 12 May 2006 6:38 by Jason13 » 12 May 2006 6:38

-

Jason13

-

- Posts: 1475

- Joined: 9 Nov 2005 11:37

- Location: UK

-

by Jason13 » 12 May 2006 6:40 by Jason13 » 12 May 2006 6:40

The one that i like the best i dont think its wiper blade cause fo the thickness of its handle but still looks nice.

-

Jason13

-

- Posts: 1475

- Joined: 9 Nov 2005 11:37

- Location: UK

-

by Shrub » 12 May 2006 7:14 by Shrub » 12 May 2006 7:14

Good effort and with useing them every day theres a supprising lack of useage marks on them.

Jason, wiper blade come in 2 sizes, the thin stuff you know and a wider one thats twice the width.

The curves are great and as suggested look like bra under wires.

How do you find the double pronged wrench? i made one like that many moons ago and it wouldnt hold up to the force needed (although i was useing it for differant locks) it just kept twisting.

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by digital_blue » 12 May 2006 9:48 by digital_blue » 12 May 2006 9:48

Looks like very nice work. I'm also curious about the curves. How do you find them? It seems like the radius is pretty large, so I'm not sure what kind of action you're getting out of those. Have you found them effective?

db

-

digital_blue

- Admin Emeritus

-

- Posts: 9974

- Joined: 6 Jan 2005 15:16

- Location: Manitoba

-

by Varjeal » 12 May 2006 9:57 by Varjeal » 12 May 2006 9:57

The shrink tubing for the handles looks good too.

*insert witty comment here*

-

Varjeal

- Moderator Emeritus

-

- Posts: 2869

- Joined: 3 Oct 2003 15:05

- Location: Western Canada

by Shrub » 12 May 2006 11:52 by Shrub » 12 May 2006 11:52

digital_blue wrote: It seems like the radius is pretty large, so I'm not sure what kind of action you're getting out of those. db

At first read i thought you had said (bearing in mind we think they are bra strips),

"It seems like the radius is pretty large, so I'm not sure what kind of action you're getting to get those"

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by pinsetter » 12 May 2006 13:39 by pinsetter » 12 May 2006 13:39

Shrub wrote:digital_blue wrote: It seems like the radius is pretty large, so I'm not sure what kind of action you're getting out of those. db

At first read i thought you had said (bearing in mind we think they are bra strips), "It seems like the radius is pretty large, so I'm not sure what kind of action you're getting to get those"

lol.......

I want some of that action too!!!

Seriously, the picks look real nice!! Good job on them!

-

pinsetter

-

- Posts: 404

- Joined: 3 Apr 2006 21:40

- Location: Bedford, Indiana USA

by raimundo » 13 May 2006 13:37 by raimundo » 13 May 2006 13:37

If there is a problem with the wishbonetensor, and it would only happen if the pressure is great, you can make another one, but use a longer piece of metal, and clamp and wire the pieces together, then using to locking pliers, about an inch or more apart, twist the center of the wishbone 360 degrees, so that there is an immobile locked up place, after which the wishbone spreads out. It will be necessary to make sure there is plenty of metal to follow the twist, which will shorten the length as its rolled in. fore and aft of the twist will need to be clamped securely against splaying before twisting. splaying is spreading in the direction perpendicular to the clamping of the pliers, you will see what I mean.

-

raimundo

-

- Posts: 7130

- Joined: 21 Apr 2004 9:02

- Location: Minnneapolis

Return to Lock Picks

Who is online

Users browsing this forum: No registered users and 1 guest

|