|

Information about locks themselves. Questions, tips and lock diagram information should be posted here.

by atrix » 17 May 2006 4:38 by atrix » 17 May 2006 4:38

Last edited by atrix on 18 May 2006 10:56, edited 1 time in total.

-

atrix

-

- Posts: 66

- Joined: 22 Sep 2005 3:43

- Location: Ukraine

by n2oah » 17 May 2006 16:23 by n2oah » 17 May 2006 16:23

He means "what are these cuts for", in case you didn't know.

-

n2oah

-

- Posts: 3180

- Joined: 13 May 2005 22:03

- Location: Menomonie, WI, USA

-

by mh » 18 May 2006 15:54 by mh » 18 May 2006 15:54

Weird...

Wild guess:

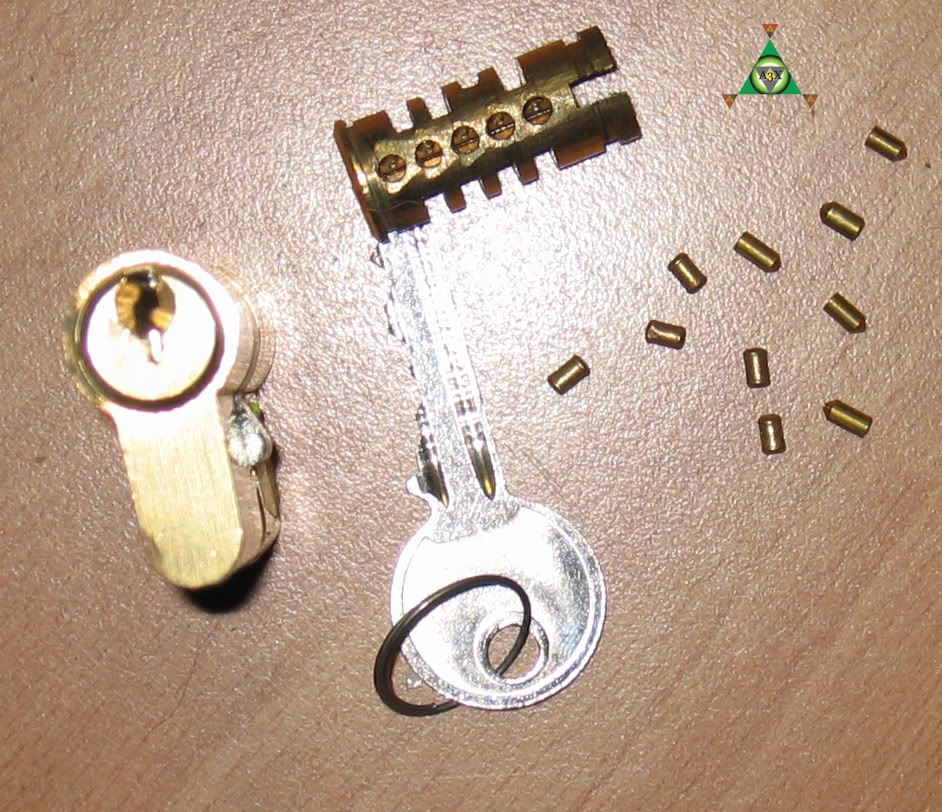

1) it's some sort of coding, as in: a plug with these cuts goes into this type of housing

2) they wanted to recycle some material

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by cracksman » 18 May 2006 21:18 by cracksman » 18 May 2006 21:18

They don't seem to have any mechanical use in the locking mechanism, that is a hell of a dent in one of those top pins though

-

cracksman

-

- Posts: 614

- Joined: 8 May 2005 19:37

- Location: Massachusetts, USA

by Gordon Airporte » 18 May 2006 23:33 by Gordon Airporte » 18 May 2006 23:33

High-performance hot rod lock, shaved down to reduce friction?

-

Gordon Airporte

-

- Posts: 812

- Joined: 15 Sep 2005 13:22

- Location: Baltimore

by raimundo » 19 May 2006 9:46 by raimundo » 19 May 2006 9:46

Cuts are offset so the driver pins do not foul into them unless a spool could manage it. perhaps they are an artifact of the manufacturing process, such as a jig to hold the plug for gang drilling.

-

raimundo

-

- Posts: 7130

- Joined: 21 Apr 2004 9:02

- Location: Minnneapolis

by ThE_MasteR » 19 May 2006 9:57 by ThE_MasteR » 19 May 2006 9:57

I think it's acting like a retaining pin, except it's on the outside of the cylinder. When you put the key in the assembled lock, can you take of the cylinder without removing anything ? If so I think those cuts are just retainers. But why go thru so much work ? me don't know lol.

-

ThE_MasteR

-

- Posts: 1128

- Joined: 14 Apr 2005 11:11

- Location: Canada, Montreal

by p1ckf1sh » 19 May 2006 10:01 by p1ckf1sh » 19 May 2006 10:01

mh wrote:1) it's some sort of coding, as in: a plug with these cuts goes into this type of housing

There should be some kind of marking/coding on the housing then as well, but I can't see any. Maybe these cuts encode the warding profile in some ingenious way, making it easy to check if two plugs are identically warde without looking too hard. Number of cuts, depth of cuts and spacing of cuts could make for easy visual discrimination, kinda like a barcode.

Just guessing though. Due to financial limitations the light at the end of tunnel has been turned off until further notice.

-

p1ckf1sh

-

- Posts: 711

- Joined: 16 Mar 2006 9:55

- Location: North Germany, Europe

by Squelchtone » 20 May 2006 1:25 by Squelchtone » 20 May 2006 1:25

mh wrote:2) they wanted to recycle some material

I think mh is right. Going into my engineering classes I thought all we would talk about is science, but instead most of what we talked about was making products for the least amount of money.

Less material = less money to produce, so I also say the slots were milled out to recycle the material into other new locks.. (cutting those grooves is a process called slotting in the machine tool industry.) Notice they didnt go too close to the face as to retain some strength, and the working end also has more material than the middle. It's interesting how they offset the slots from the pin holes, and how one slot is not as deep as its brothers.

Squelchtone

________________________________________________

The simplest answer is usually the correct answer.

-

Squelchtone

- Site Admin

-

- Posts: 11335

- Joined: 11 May 2006 0:41

- Location: right behind you.

by atrix » 20 May 2006 6:24 by atrix » 20 May 2006 6:24

hi all

thanks for the answers

I think that these сuts they make for the savings of the material

but it is heavy to understand Chinese

this lock good to pick with racking picks in paar sec. but pin by pin it does not work

Such form pins complicates opening by that that all pins different also is used with greater admissions and consequently while lower one pin two lift back

-

atrix

-

- Posts: 66

- Joined: 22 Sep 2005 3:43

- Location: Ukraine

by p1ckf1sh » 20 May 2006 9:16 by p1ckf1sh » 20 May 2006 9:16

squelchtone wrote:I think mh is right. Going into my engineering classes I thought all we would talk about is science, but instead most of what we talked about was making products for the least amount of money.

Less material = less money to produce, so I also say the slots were milled out to recycle the material into other new locks..

Hmmm. Does it make sense economically? I mean the plug aint that big, so the material saving aint that big. Sure you can take the shavings from maybe 8-10 plugs to make a new one, but the plug is first made completely, then milled. That adds another machine to be used, another step in the production cycle, etc.

But maybe you are right...

The chinese are weird people. But lovely as long as they don't roll over demonstrating students in battle tanks...

No offense, just thinking out aloud Due to financial limitations the light at the end of tunnel has been turned off until further notice.

-

p1ckf1sh

-

- Posts: 711

- Joined: 16 Mar 2006 9:55

- Location: North Germany, Europe

by SFGOON » 20 May 2006 13:36 by SFGOON » 20 May 2006 13:36

Did anyone else notice that the top of that plug has been filed down a touch?

Honestly, who knows why they Chinese do anything. My bet is some sort of Feng-Shue, but it should be noted that I'm grossly ignint.

"Reverse the obvious and the truth will present itself." - Carl Jung

-

SFGOON

- Admin Emeritus

-

- Posts: 2160

- Joined: 9 Sep 2004 14:04

- Location: Puget Sound, WA

by mh » 20 May 2006 14:52 by mh » 20 May 2006 14:52

SFGOON wrote:Did anyone else notice that the top of that plug has been filed down a touch?

Sure, I guess that's part of the deburring process after drilling the holes.

Assuming that this is all done manually, as I would expect.

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by n2oah » 20 May 2006 15:44 by n2oah » 20 May 2006 15:44

mh wrote:SFGOON wrote:Did anyone else notice that the top of that plug has been filed down a touch?

Sure, I guess that's part of the deburring process after drilling the holes. Assuming that this is all done manually, as I would expect.

Yes, I've seen locks with the same filing marks. I've seen locks with parts of the plug shaved off. There was a National brand padlock I found that had the right side shaved off (this was possible because it was a one-way cylinder) "Lockpicking is what robbing is all about!" says Jim King.

-

n2oah

-

- Posts: 3180

- Joined: 13 May 2005 22:03

- Location: Menomonie, WI, USA

-

by conker » 23 May 2006 13:20 by conker » 23 May 2006 13:20

wow, that is a mystery. There are several good ideas on this though, I think the one that it uses less materials is good though. It makes sense, since that is the only real reason why they would do something like that.

-

conker

-

- Posts: 55

- Joined: 2 Feb 2006 1:13

Return to Locks

Who is online

Users browsing this forum: No registered users and 2 guests

|