|

When it comes down to it there is nothing better than manual tools for your Lock pick Set, whether they be retail, homebrew, macgyver style. DIY'ers look here.

by pinsetter » 29 Aug 2006 13:26 by pinsetter » 29 Aug 2006 13:26

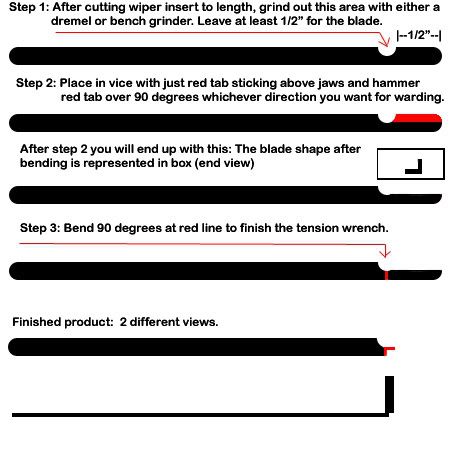

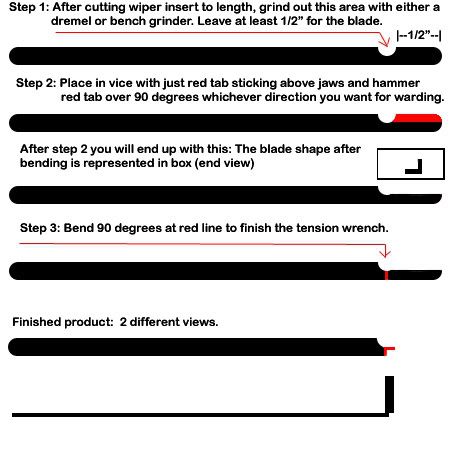

I posted these instructions in another thread, but thought this should get its own thread so people can find it. The instructions are for tension wrenches with blades that are bent to fit warding and prevent binding of the tension wrench on the cylinder walls. These will work on a vast majority, but not all keyways and a few of these will have to be made for different warding patterns. I will try to post pictures of the actual finished tensors in the next couple of days.

OK, here are instructions for making these tensors:

-

pinsetter

-

- Posts: 404

- Joined: 3 Apr 2006 21:40

- Location: Bedford, Indiana USA

by Shrub » 29 Aug 2006 16:46 by Shrub » 29 Aug 2006 16:46

That seems a good idea i think it will be a good one for dimple locks as well like the gemini and MTL's etc,

Good work,

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by linty » 29 Aug 2006 18:47 by linty » 29 Aug 2006 18:47

i tried to make this a while back but failed.

what do you use for material?

-

linty

-

- Posts: 631

- Joined: 26 Feb 2005 22:42

- Location: Ottawa, Canada

by machinist » 29 Aug 2006 20:24 by machinist » 29 Aug 2006 20:24

Did you use a square jaw vice and hammer for the first bend?

If you can't make it work try yelling "aww d*****t!" and throwing your tools it never worked for my pops but it entertained me

-

machinist

-

- Posts: 170

- Joined: 29 Oct 2005 7:45

- Location: West los angleles, california

by unbreakable » 29 Aug 2006 21:05 by unbreakable » 29 Aug 2006 21:05

Neat concept, It'll be especially useful for locks with really pacentric warding.

Could you make a specially shaped one , made to fit in a nasty Best keyway, with teeth to fit in the bottom of the sleeve?

That'd be a very useful thing.....

But it'd be hard to make all the bends, maybe it'd have to be cast?

Just a though.

-

unbreakable

-

- Posts: 1682

- Joined: 28 Oct 2005 18:55

- Location: Nova Scotia, Canada

by Schuyler » 29 Aug 2006 23:17 by Schuyler » 29 Aug 2006 23:17

I replied in the other thread, but, again, nicely done and thank you for putting this together.

-

Schuyler

- Supporter

-

- Posts: 3448

- Joined: 24 Jul 2006 1:42

- Location: Boston

-

by pinsetter » 30 Aug 2006 11:04 by pinsetter » 30 Aug 2006 11:04

For all my tensors I use only inserts from Anco 30-16, or 30-20 Wiper blades.

The Anco blades have the best inserts I've found to date.

For the first bend I do use a square jawed vice and a good heavy ball peen hammer. I hammer slowly so the metal does not crack at the sharp bend.

*When hammering the lengthwise bend in the metal I sometimes have to re-insert the piece in the vice several times!*

I mentioned this in another thread also but I'll do so again here:

These tensors will also teach you NOT to apply excessive tension when picking. There is an inherent weak spot created by grinding half the cross section of the wiper insert away. This is where the handle and blade meet. If you apply too much tension with these tensors the metal will twist and bend at the weak area. If you get bending or twisting you are definately applying way too much tension (except in turning the plug on American brand padlocks which require much tension to overcome the cam spring). Repeated bending leads to rapid breakage in stainless steel, and these tensors are not the easiest to make all the time, so if you like them you learn to keep them intact.

-

pinsetter

-

- Posts: 404

- Joined: 3 Apr 2006 21:40

- Location: Bedford, Indiana USA

Return to Lock Picks

Who is online

Users browsing this forum: No registered users and 1 guest

|