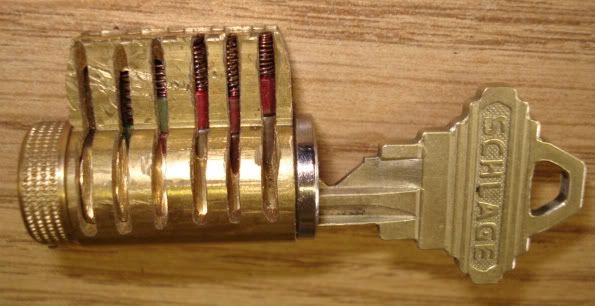

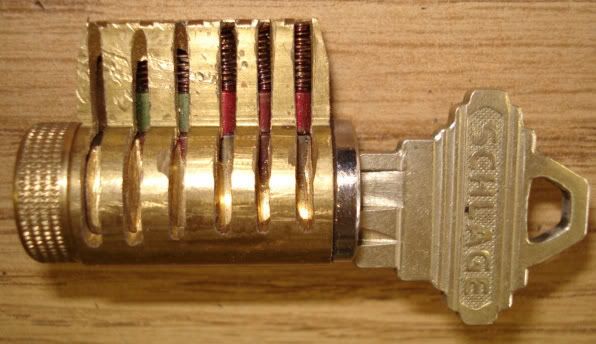

This is a Schlage 6 pin cylinder I cut notches into many years ago, to aid me in practising lock picking. Schlage brand of cylinders have been one of the tougher ones for me to pick, so I though that if I could see what was going on inside, it could help me to improve my technique.

I used a Rotary Tool with a cut off wheel to cut notches into the cylinder plug and outer casing. Then smoothed off any rough edges with a file.

Seeing the tumblers from the side while picking, gives me the visual confirmation when a pin tumbler is sucessfully being held above the shear line. I know this is cheating, but it's just an aid to get the feel of what goes on.

Here are some pictures: