|

When it comes down to it there is nothing better than manual tools for your Lock pick Set, whether they be retail, homebrew, macgyver style. DIY'ers look here.

by Peter Martin » 19 Nov 2006 20:45 by Peter Martin » 19 Nov 2006 20:45

Does anyone have an impressioning clamp or handle design they'd like to share?

Or modifications to vise-grips for impressioning?

I was just searching for a way to make impressioning easier--and more comfortable. I saw some designs on the US Patent website that didn't look very difficult to make--i.e. a slot in the end of a piece of solid aluminum barstock, with a screw-and-wingnut through the slot to secure the keyblank. I thought that might be easy enough to duplicate.

-

Peter Martin

-

- Posts: 396

- Joined: 1 Aug 2004 0:14

- Location: SD

by iNtago » 19 Nov 2006 20:50 by iNtago » 19 Nov 2006 20:50

there got to be a complicated part

it sounds too easy

-

iNtago

- Supporter

-

- Posts: 479

- Joined: 10 Sep 2006 18:45

- Location: Brenham, Texas

-

by Romstar » 20 Nov 2006 2:03 by Romstar » 20 Nov 2006 2:03

Nope.

Most of the are that easy. Some use allen screws so that the "look" is nice and clean, but by and large, thats how they are made.

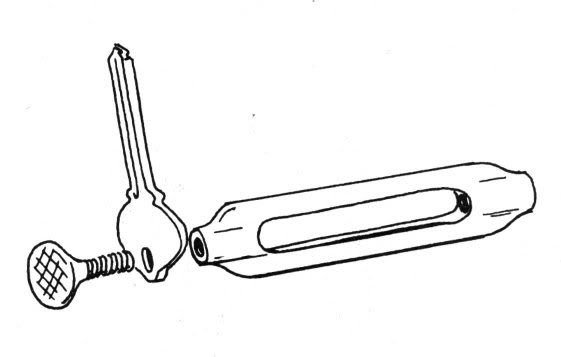

Or, you can try this:

That should fit the bill until you make something "professional" looking.

Romstar

-

Romstar

-

- Posts: 2823

- Joined: 18 Apr 2004 3:13

- Location: Nova Scotia, Canada

by Shrub » 20 Nov 2006 9:46 by Shrub » 20 Nov 2006 9:46

There are a few differant designs of clamp, the one shown above is the most simplist along with the aloy bar with a slot in it but there are also other types around old and new,

If you are in the advanced section there is a post on one that actually has a mech in it so it marks the key better, take a look,

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by ufd538 » 22 Nov 2006 1:04 by ufd538 » 22 Nov 2006 1:04

Well I started off like most with vise grips.

Along the way I had an idea I never got to.

Then I bought the framon handle tool...works nice, but on a few keys not so much.

So after a while I went back to my idea. Originally I did not want to buy and ruin a pair of vise grips if it didn't work. I took a gamble of buying a $55 handle, but didn't want to ruin a $12 pair of vise grips....go figure.

Anyways notice on a pair of needle nose vise grips that the jaws are somewhat parallel, especially in the middle. So what I did, was get a mid level pair of vise grips $7 and cut around an inch or so off the tips. They work real nice. Nice overall grippage, instead of just at the tip, like most vise grips. I got mine at harbor freight tools, the nicest off brand ones...Pittsburgh Pro-Series or something, red and black handles.

Anyways, use your judgement where to cut, it is probably different depending on the manufacturer.

Now I thought I was screwed when I first cut it, because it doesn't shut all the way once you cut it, but it still shuts enough to give a real nice grip.

When and if these wear out I will try it with a nicer pair.

Here is a link to a pic to envision what I am saying, though it is easier to see a set in person.

http://www.sears.com/sr/javasr/product. ... Cookie=Yes

-

ufd538

-

- Posts: 160

- Joined: 23 Dec 2004 0:11

- Location: Ohio, USA

by Peter Martin » 22 Nov 2006 10:57 by Peter Martin » 22 Nov 2006 10:57

Did you grind the inside of the jaws smooth or make them parallel?

I was thinking of something similar with a small (5-6") pair of used vise-grips.

The commercial vise-grips which distributors sell for impressioning seem to have some sort of "lump" in the jaws, possibly for securing the key via the hole in the blank--but I haven't seen a clear enough picture to reproduce the jaws.

I guess if I wanted to do duplicate such a lump, I could drill/tap a hole and then put a small machine screw into the jaws. But I really don't kow what the advantage to this might be. If you grind the face of the jaws smooth, you'll have a larger and smooth area to secure your key. I don't think it takes a lot of pressure to secure the key.

-

Peter Martin

-

- Posts: 396

- Joined: 1 Aug 2004 0:14

- Location: SD

by Peter Martin » 22 Nov 2006 14:19 by Peter Martin » 22 Nov 2006 14:19

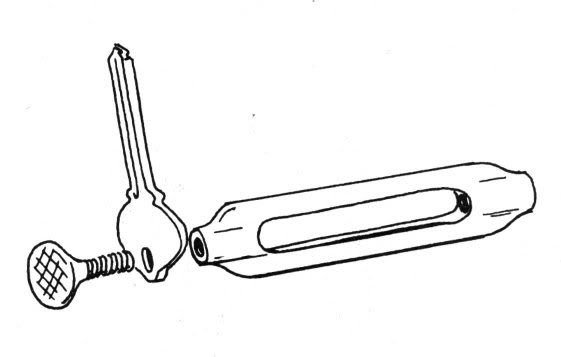

This is a photo of the Lockmasters' Imp-Grip. I guess I just don't understand why this jaw shape would make it grip a keyblank any better.

-

Peter Martin

-

- Posts: 396

- Joined: 1 Aug 2004 0:14

- Location: SD

by ufd538 » 22 Nov 2006 19:09 by ufd538 » 22 Nov 2006 19:09

nope just cut off the tips. I cut the tips and rounded the sharp edge left from the cut. That's it.

a large smooth surface may be perfect for the key to slip on. The jaws are already somewhat parallel

I know it sounds too easy, trust me it works. I have an impression handle and every style vise grip, and I use the modified needle nose and that is it. Heck I used to keep 3 different pairs of vice grip with my files, now just this one small pair. Trust me, just try it. I will see if I can post a picture, within the day.

-

ufd538

-

- Posts: 160

- Joined: 23 Dec 2004 0:11

- Location: Ohio, USA

by Shrub » 23 Nov 2006 8:19 by Shrub » 23 Nov 2006 8:19

Peter,

To me it looks like they have been designed to also acomodate lever lock keys, the 'V' on the bottom jaw being to site the round stem of the keys but i could be wrong having not seen them in the flesh,

The only thing ive seen was done by Jimmie at the dutch open, he notched the key bow a bit so the back of the jaws on the mole grips fitted in it, this stopped it moving in the grips,

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by Kaotik » 23 Nov 2006 17:52 by Kaotik » 23 Nov 2006 17:52

Here's something I came up with, I had this handle that I didn't have any use for but I kept it just incase.

Nothing fancy but it works, and it might get some ideas flowing.

I also added a pretty thick piece of feeler guage so it will double as a small hand vice.

-

Kaotik

- Moderator Emeritus

-

- Posts: 1200

- Joined: 10 Jun 2006 13:38

- Location: Texas, USA

by adam cooper » 12 Dec 2006 14:20 by adam cooper » 12 Dec 2006 14:20

if a regular pair of visegrips is not working for you you not doing it right

if the key is moving in the jaws ther are three things you can do to change that 1 the key blank is not setting in the jaws correctly ,try with moving the key blank to a different position 2 the jaw is not tight enough 3 your bumping to hard there are some thing that ive seen on this web site that are not good ideas ,bad inventions,ect a handle with a screw in it is not going to work, if it so not that well it looks like you can only apply turning pressure , thats not the right way to do it ...you need slight turnig pressure at the same time bumping the pins or waffers... and im not talking about hitting the back of it with a locksmith hammer... you turn the key with a little pressure and move the key up and down ..if you are just using turning pressure your not going to get the marks that you want and will end up breaking many keys javascript:emoticon(':shock:')

-

adam cooper

-

- Posts: 2

- Joined: 12 Dec 2006 10:43

by ridderhenck » 15 Mar 2007 13:49 by ridderhenck » 15 Mar 2007 13:49

I made one out of pvc,4 sludges,one screw.you drill two holes,put the screw through the holes,on the right a sludge on the ouside of the tube,but before that you put a sludge,a blank key and another sludge through the screw on the inside of the tube,with an 8-wrench you close the key between the two inner sludges and go file a new key!!!!i hope I make sense  the sky is the limit

-

ridderhenck

-

- Posts: 193

- Joined: 24 Jan 2007 16:10

- Location: The Netherlands

by Shrub » 15 Mar 2007 19:32 by Shrub » 15 Mar 2007 19:32

You have to tell me what a sludge is as that over here is what you call crap,

Kaotic, although perhaps a bit straight forward in the way he said it he has a point, its the same thing i thought of when i saw your pics,

Theres nothing to stop the key swinging up or down no matter how hard you tighten the screw you will still find the key moves,

I understand its an idea and a quick go at it so i can perhaps suggest an improvement if i may?

Simply drill another hole either side of the first hole, make these holes closer to the front edge than the first one and closer to the side edges,

This would allow you to use another bolt to go through each of the holes and act as a sort of stop for the bow,

-

Shrub

- Moderator Emeritus

-

- Posts: 11576

- Joined: 23 May 2005 4:03

- Location: uk

by Kaotik » 15 Mar 2007 21:15 by Kaotik » 15 Mar 2007 21:15

Shrub, I appreciate the suggestion. I thought of that at the time when I chose to use that handle, I just improvised by using locking washers instead of making such a modification. The handle already has two large holes in it, one in front of the other, and not much space to use for that suggestion. But thanks.

The image Romstar posted would do the same thing considering the rocking motion involved. Instead of having your hand positioned to the side, I thought the straight forward approach to more of an advantage.

Wow! I posted those images over 3 months ago....

-

Kaotik

- Moderator Emeritus

-

- Posts: 1200

- Joined: 10 Jun 2006 13:38

- Location: Texas, USA

Return to Lock Picks

Who is online

Users browsing this forum: No registered users and 5 guests

|