|

Picked all the easy locks and want to step up your game? Further your lock picking techniques, exchange pro tips, videos, lessons, and develop your skills here.

by Lauren » 28 Nov 2006 23:56 by Lauren » 28 Nov 2006 23:56

I love making locksmith tools, and there's an idea that I've been kicking around for years, and yes, it's probably easier to impression a lock, but I like challenges.

Imagine picking a lock (one that can't be disassembled when opened), and being able to to insert a key like instrument that has percise probes built into it that could measure the heights of each pin. The data could then be used to cut a key from code. Now naturally, there's going to be key way patterns where this so-called de-coder just won't work. But just for fun, let's start simple- say, a master lock with an M1 key way. If you were good, maybe you could read the first two pins (reading is nothing new, it's sometimes used on disc pin locks to make a key). I believe the idea has already been done for some brands of locks in the automotive industry. Nonetheless, I like to here from some of you to design this de-coder. I think it would be fun.

-

Lauren

-

- Posts: 437

- Joined: 20 Oct 2006 22:58

by JackNco » 29 Nov 2006 0:09 by JackNco » 29 Nov 2006 0:09

Well all the best 2 u, i would have no idea where 2 start. but if u need a programmer to compile all the *data* let me know

-

JackNco

-

- Posts: 3149

- Joined: 14 Apr 2006 12:26

- Location: Coventry. UK

by Lauren » 29 Nov 2006 0:21 by Lauren » 29 Nov 2006 0:21

Each de-coder would have to be lock specific. Remember, pin sizes in most American or Master brand locks range from 0-6. So, I don't see why a computer would be necessary. The tool would have to be designed and callibrated to read each pin for a specific keyway and lock manufacturer.

Lauren.

-

Lauren

-

- Posts: 437

- Joined: 20 Oct 2006 22:58

by Schuyler » 29 Nov 2006 0:27 by Schuyler » 29 Nov 2006 0:27

Lauren wrote:I love making locksmith tools, and there's an idea that I've been kicking around for years, and yes, it's probably easier to impression a lock, but I like challenges. Imagine picking a lock (one that can't be disassembled when opened), and being able to to insert a key like instrument that has percise probes built into it that could measure the heights of each pin. The data could then be used to cut a key from code. Now naturally, there's going to be key way patterns where this so-called de-coder just won't work. But just for fun, let's start simple- say, a master lock with an M1 key way. If you were good, maybe you could read the first two pins (reading is nothing new, it's sometimes used on disc pin locks to make a key). I believe the idea has already been done for some brands of locks in the automotive industry. Nonetheless, I like to here from some of you to design this de-coder. I think it would be fun.

Sounds like a sputnik tool.

-

Schuyler

- Supporter

-

- Posts: 3448

- Joined: 24 Jul 2006 1:42

- Location: Boston

-

by TOWCH » 29 Nov 2006 2:16 by TOWCH » 29 Nov 2006 2:16

A set of picks that were designed for the purpose seems like the easiest route.

-

TOWCH

-

- Posts: 1587

- Joined: 20 Jul 2004 0:19

- Location: Oregon

by maxxed » 29 Nov 2006 2:17 by maxxed » 29 Nov 2006 2:17

With a little practice you can guage depths off a hook pick, just trace the pins with the pick and guage the lenght of the pin by observing how close the bottom of the piok comes to the bottom of the keyway. Start with locks that use larger steps between cuts like a kwickset (.023) before trying a master (.016)

-

maxxed

-

- Posts: 736

- Joined: 18 Mar 2006 12:09

- Location: Saskatchewan, Canada

by Squelchtone » 29 Nov 2006 2:38 by Squelchtone » 29 Nov 2006 2:38

Schuyler wrote:Sounds like a sputnik tool.

dude, exactly what I was thinking. but then... what about an automatic sputnik like a robodialer for safes?

it tries different bitting combinations, and it's motors/solenoids can be externally controlled by software to skip impossible combinations or when it comes to MACs (max adjacent cuts)....

hmmm put it in keyway, calibrate, and run software... hmmm.

-Squelchtone

-

Squelchtone

- Site Admin

-

- Posts: 11336

- Joined: 11 May 2006 0:41

- Location: right behind you.

by raimundo » 29 Nov 2006 13:09 by raimundo » 29 Nov 2006 13:09

how about a piece of metal that has one end that goes into the lock and sets against the bottom of the keyway against the cylinder wall, and extends outside the keyway in a wider piece, along this wider piece, you would have a second piece that goes into the lock and probes the pins while pressing them into the cylinder wall, which would represent the shearline, the second piece, the probe, would be attached to a pivot axle on a piece of metal that slides along the first piece, all this slideing and pivoting would have to be very tight tolerances, and the piec that pivots, would have an indicator that either reads on a scale printed on the first piece of metal, or it could be equiped with a pencil point so that as it is slid in the pencil traces the outline. the precision that would be needed requires very tight tolerances to reduce error. Or look at falles catalog, theres probably already one of these.

-

raimundo

-

- Posts: 7130

- Joined: 21 Apr 2004 9:02

- Location: Minnneapolis

by Romstar » 29 Nov 2006 14:43 by Romstar » 29 Nov 2006 14:43

There are already several of these tools.

The most common application is for automotive locks, but the concept has been used for regular pin tumbler locks as well.

Some use a scale, others actually draw a tracing of the lock. They all function on the same technique and premis.

The drawback to these devices is when you change springs or worse, the driver pins.

They are non functional in IC locks, as IC core locks use what is known as fixed stack adjustment, utilizing different sizes of driver pins to maintain the same depth of the pin stack when compressed.

Its a good idea, and I comed you on coming up with the thought on your own.

Check the Lockmasters catalogue for similar tools, and also MBA and MCS for other varients on these tools.

Romstar

-

Romstar

-

- Posts: 2823

- Joined: 18 Apr 2004 3:13

- Location: Nova Scotia, Canada

by TOWCH » 29 Nov 2006 21:16 by TOWCH » 29 Nov 2006 21:16

Are high-low bittings a problem for such a tool?

-

TOWCH

-

- Posts: 1587

- Joined: 20 Jul 2004 0:19

- Location: Oregon

by Romstar » 29 Nov 2006 22:50 by Romstar » 29 Nov 2006 22:50

TOWCH wrote:Are high-low bittings a problem for such a tool?

Not normally. The tool is meant to decode each pin stack seperately, and then you use the code to create a key that will operate the lock.

As I said, it does run into problems with locks such as the BEST IC core, or anything that follows the same standard. If each stack is the same length because of variable driver pins, the decoder just doesn't work.

Now, on the other hand if you are decoding a picked lock then you won't have to worry about the drivers.

This is where high, low, high problems could come in. If the reader can't reach over a deep in, it can't read anything beyond.

Romstar

-

Romstar

-

- Posts: 2823

- Joined: 18 Apr 2004 3:13

- Location: Nova Scotia, Canada

by zeke79 » 29 Nov 2006 23:03 by zeke79 » 29 Nov 2006 23:03

As Romstar says, there are alot of these tools out there for sure. Adapting a few for say schlage SC1, Yale Y1, Master M1 and Kwikset KW1 would net someone a decent amount of money.

Why you ask????

Alot of locksmiths can either pick locks or impression them, sometimes both but from what I have seen this is not all that common. You would be making a tool that locksmiths who can pick but not impression that would allow them to decode the lock after picked. Could be a big money maker.. With the depth differances being .015" between cuts or less it may not be all that hard to do if you worked at it.

For the best book out there on high security locks and their operation, take a look at amazon.com for High-Security Mechanical Locks An Encyclopedic Reference. Written by our very own site member Greyman! A true 5 Star read!!

-

zeke79

- Admin Emeritus

-

- Posts: 5701

- Joined: 1 Sep 2003 14:11

- Location: USA

-

by zeke79 » 29 Nov 2006 23:21 by zeke79 » 29 Nov 2006 23:21

I need to state another point on this thread too. Some lockies who cannot impression is due to eyesight. I can pick locks at a level I feel to be above average, but I cannot impression well. I have to have a perfect fixed light source to do it. That I am almost positive is cause by my eyesight.

This tool could very well help people like me.

For the best book out there on high security locks and their operation, take a look at amazon.com for High-Security Mechanical Locks An Encyclopedic Reference. Written by our very own site member Greyman! A true 5 Star read!!

-

zeke79

- Admin Emeritus

-

- Posts: 5701

- Joined: 1 Sep 2003 14:11

- Location: USA

-

by GoodEyeSniper313 » 30 Nov 2006 1:54 by GoodEyeSniper313 » 30 Nov 2006 1:54

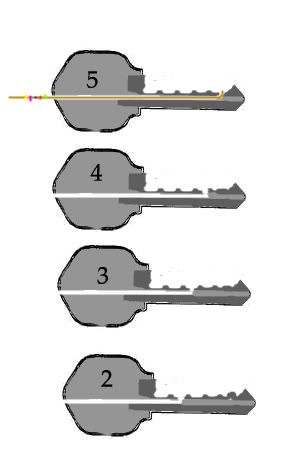

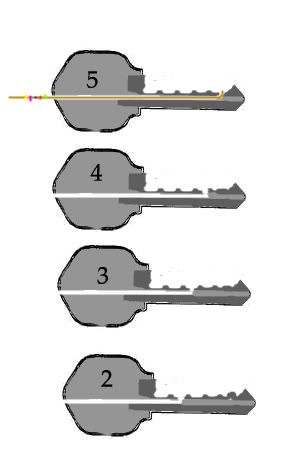

ok heres what came up with

basicly u have 5 different key blanks with cut (999) with a routed groove going to a pin slot. each blank goes to a different pin slot. then a piece of music wire is inserted into the groove. the wire is marked to by color to show diferent pin sizes.

so u would simply pick the lock, then while its picked you insert blank #5 into the lock and push in the wire until the pin hits the cylinder wall if the wire goes in all the way to the second colored line u know that pin is a 2. so you know pin 5 is a 2. now ud put in blank #4 and repeat until you have all 5 measurements.

this is just an idea im not a locksmith and i dont know how practical this tool would be. "you cant just grind a hacksaw blade down and expect to pick locks with it" quote from my friend in the 10th grade when i first tried picking a lock

-

GoodEyeSniper313

-

- Posts: 11

- Joined: 23 Nov 2006 2:59

- Location: florida , america

by zeke79 » 30 Nov 2006 2:11 by zeke79 » 30 Nov 2006 2:11

The problem with using wires is that they are easily bent out of adjustment.

I am hoping my insomnia is over now so I can go to to bed.....

For the best book out there on high security locks and their operation, take a look at amazon.com for High-Security Mechanical Locks An Encyclopedic Reference. Written by our very own site member Greyman! A true 5 Star read!!

-

zeke79

- Admin Emeritus

-

- Posts: 5701

- Joined: 1 Sep 2003 14:11

- Location: USA

-

Return to Pick-Fu [Intermediate Skill Level]

Who is online

Users browsing this forum: No registered users and 8 guests

|