Here are a few hints when you try to do this.

1. I started with drain snake .250" high x .025" thick.

2. Use Dykem blue and paint the end.

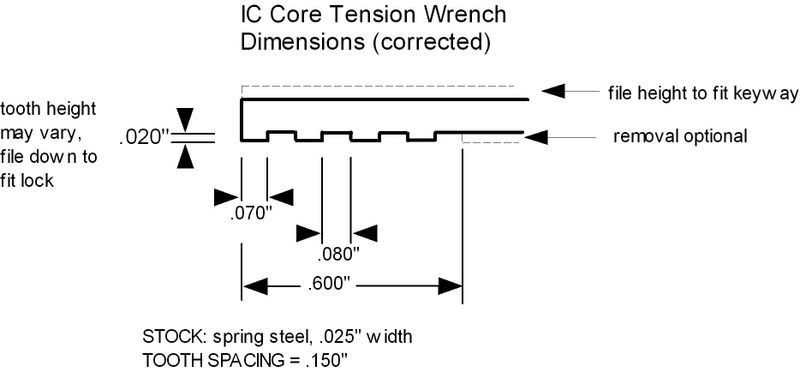

3. The measurements given on most of the templates for this should be corrected for accuracy and convenience. The template indicated the teeth should be 5/32" (.156") apart. The actually pin spaces for Best and most IC cores is .150". The IC core template also mixes fractions of inches with decimals. I decided to use all demical (thousandths of an inch) and used a dial indicator to set and scribe my lines on the stock. The teeth on the template are shown to be a "maximum" of .070". I don't know why this is the max width of the teeth because the pin holes for Best are .108". However, .070" seems like a good conservative size tooth, so we'll use this measurement.

4. The following lines should be scribed vertically along the stock: .070, .150, .220, .300, .370, .450, .520, and .600. These lines will give you a tooth width of .070" and a space between the teeth of .080". The distance from tooth-to-tooth will equal the actual Best pin spacing of .150".

5. Clamp the stock in a small vise.

6. Now ready to file the spaces between the teeth. I used the narrowest of my fine-cut flat needle files to make the slot. The critical part is to get the slots cut straight down and to the same depth. It doesn't matter how deep the cuts are as long as they are generally to the same depth--because it's easier if you file the teeth to the correct height as your last step.

6. Use a fine triangle needle file to true the sides of the slots vertically and the bottoms flat. This process is the critical step. Use a good light and work slowly, taking only a stroke or two at a time. Remember the depth doesn't matter yet.

7. Use your dial calipers to check that the teeth are all an even width--with some tolerance. Mine are within about .005". Measure the spaces between and get them even. If one space is too small and the adjoining tooth too large, carefully file the edge of the adjacent side of the tooth using your triangle needle file. Measure the depths of the cuts to make sure they are also similar.

8. Using a file that is wide enough to span two or three teeth, cut down the height of the teeth to the proper depth. I found that .012" as indicated on the template was pretty shallow. Because the teeth can always cut them down a little farther, so I left mine high--at around .020". If this doesn't work, I can file them down a few thousandths at a time. Use a file that spans two or more teeth just to get the teeth to a similar height. It's easier than filing the teeth individually.

9. Once all the teeth are filed, you can flip the stock over. Place it evenly in the vise. You can now draw file (holding you file crossways and pushing is back & forth) the whole back-side until the entire length of the wrench is the height you want. Not including the height of the teeth, the height of mine is about .110". If this height is not optimium, I can always file it down a little later to fit.

10. If you are happy with the shape of the teeth, the general height of the wrench, polish and bend the tension wrench. I used a torch to heat the metal slightly (because my first attempt cracked and broke--let me tell ya, I was rather upset at this). With the teeth upward in the vise, bend the wrench to the left (so when the teeth are down, the handle will be to the right). Don't laugh, I did this incorrectly on my the first attempt.

Here is the result...

The entire process took about 1-1/2 hours. Save your eyes and work slowly and with a good light. A headband magnifer would help, but I don't have one. Sharp needle files are required.

Now all I need is an IC lock to test this out on!

Good luck!