|

THE starting place for new members. FAQ's, instructions on how to pick a lock, valuable information like product reviews, links to lock picking related sites, forum rules, lockpicking tool vendors, and more. START HERE.

by tballard » 1 Apr 2009 11:04 by tballard » 1 Apr 2009 11:04

I'm strongly of the opinion that the tension tool is often as important as the pick. Lately I've been making more and more top-tension tools, and wanted to share my latest creation. The source material was 1/8" steel rod. Usually I use 3/32", but decided to try something new. The wrench is designed so it fits extremely snugly into the top of a Medeco lock, and can be used either vertically or horizontally. The larger stock gives more contact at the face of the lock, making the fit more secure. All work was done with hand files except for cutting the steel, which was done with a cutoff wheel. The polish was obtained by working up to 2000 grit sandpaper and 000# steel wool. As you can see, the tool fits snugly enough to stay in place without being held.    (all images clickable) Last edited by MBI on 9 Jan 2016 5:26, edited 1 time in total.

Reason: Moved to the proper forum.

-

tballard

-

- Posts: 225

- Joined: 29 Dec 2008 21:14

- Location: Austin, TX

by freakparade3 » 1 Apr 2009 11:08 by freakparade3 » 1 Apr 2009 11:08

Very nice. I made a poll about a year ago due to all the new pickers asking "What pick is the best?". I am of the opinion the tension tool is far more important than pick choice. The poll showed the majority of experienced pickers agreed.

-

freakparade3

- Moderator Emeritus

-

- Posts: 3457

- Joined: 17 Sep 2006 12:01

- Location: Cedar Rapids, Iowa

by Olson Burry » 1 Apr 2009 11:20 by Olson Burry » 1 Apr 2009 11:20

Cool, nice work.

I'm with freakparade3 as well, give me but three picks and 10 wrenches I'll be happy. You can never have enough wrenches.

On a side note, I've found bicycle spokes pretty handy for wrenches, they shine up pretty well too.

-

Olson Burry

-

- Posts: 405

- Joined: 19 Jun 2008 19:39

- Location: Brighton, UK

by tballard » 1 Apr 2009 12:30 by tballard » 1 Apr 2009 12:30

Thanks for the kind words.  Olson Burry wrote:On a side note, I've found bicycle spokes pretty handy for wrenches, they shine up pretty well too.

Really? Interesting. I always thought they would be too thin (or in some cases hollow). I'll have to look into them. My current favorite material is actually "landscape staples" which are used for securing weed block fabric to the ground. They are 6 inches of hardened 11 gauge steel, bent in a "U". The problem with both landscape staples and the steel rod I used is that they aren't stainless, and thus may require some care to avoid rust.

-

tballard

-

- Posts: 225

- Joined: 29 Dec 2008 21:14

- Location: Austin, TX

by femurat » 2 Apr 2009 8:09 by femurat » 2 Apr 2009 8:09

Impressive! You made an excellent work on this wrench! How could you get so precise bend? If you wanna play with spokes, I've made this experiment and worked surprisingly well! With your metal working skills the result could be fantastic! Let us know

-

femurat

- Site Admin

-

- Posts: 3765

- Joined: 22 Sep 2008 9:06

- Location: Italy

by tballard » 2 Apr 2009 11:02 by tballard » 2 Apr 2009 11:02

femurat wrote:Impressive! You made an excellent work on this wrench!

How could you get so precise bend?

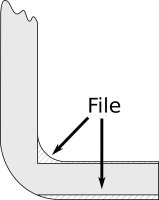

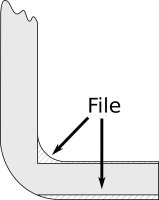

Thank you. The bend is actually quite easy, but I'm not totally happy with the technique. To make it, I simply clamp the wire in a vise vertically, and place a rectangular piece of stainless steel behind what will become the inside radius of the bend. Then I just "persuade" the stock into the bend using a series of light hammer strokes. You have to go to just a hair over 90 degrees since the metal springs back. What you are aiming for is mainly at close to a 90 degree bend as possible, with the inside radius as small as you can manage. Once you've got that, you use a file to remove the remaining curve. Here is a picture:  The reason I don't like this technique is that you put a lot of stress on the metal when you bend it so severely. Making the bend slowly using a lot of hammer taps helps, but it's still far from ideal. I've also experimented with either undercutting the inside radius with a file before bending and/or bending after heating with a propane torch and then quenching. Each has drawbacks, but my highly unscientific experimentation has convinced me that a careful cold bend with no undercut is strong enough. femurat wrote:If you wanna play with spokes, I've made this experiment and worked surprisingly well! With your metal working skills the result could be fantastic!

Very nice work there, I might have to try that next.

-

tballard

-

- Posts: 225

- Joined: 29 Dec 2008 21:14

- Location: Austin, TX

by Artkrp » 3 Apr 2009 2:09 by Artkrp » 3 Apr 2009 2:09

"landscape Staples" huh? Do you have a picture of these available? They sound pretty interesting...

good work on the tension rod too, that thing looks pretty hot!

*witty lock-related comment here!*

-

Artkrp

- Supporter

-

- Posts: 145

- Joined: 22 Nov 2007 8:53

- Location: Anchorage AK

by tballard » 3 Apr 2009 9:06 by tballard » 3 Apr 2009 9:06

Artkrp wrote:"landscape Staples" huh? Do you have a picture of these available? They sound pretty interesting...

good work on the tension rod too, that thing looks pretty hot!

Here's a link to Home Depot's website to them: link Hopefully the link works. (It's a pretty heavily "sessioned" link so it's hard to be sure) If not, just search for "landscape staples". I'm planning on making a few more wrenches soon, and if I do, I'll try to take pictures of the process. (Hmm, I wonder if I should take advantage of the "be the first person to write a review" option on the HD site, and tell them how wonderful they are for lockpicking  )

-

tballard

-

- Posts: 225

- Joined: 29 Dec 2008 21:14

- Location: Austin, TX

by Engineer » 3 Apr 2009 22:03 by Engineer » 3 Apr 2009 22:03

Yep, the link works fine! Unfortunately they only say they are made of "steel" on the website, do you know if they are stainless or not? I'm so hoping they are stainless... Actually, the typical way to bend metal like this is with a "jig". In this case you could make a really posh one if you wanted, but two fairly heavy nails or screws driven into a piece of wood will work just as well. They should be spaced just slightly wider apart than the thickness of the wire. The radius of the bend you will get, will be pretty close to the radius of the nail or screw you use. You just place the wire between the two nails or screws and bend it. You might need a little practise to get it to bend only at the point you want it to. If you are having problems with thew main body of the wire bending, "persuade" it round the nail or screw by tapping it with a heavy hammer near the nail or screw. If you really want to take all the skill out of it, you just slip a narrow tube over the wire to about 1/4" from where you want the bend making and use the tube almost like a giant "wrench" to bend the wire.

-

Engineer

-

- Posts: 584

- Joined: 21 Aug 2008 14:53

- Location: UK

by ToolyMcgee » 8 Apr 2009 10:26 by ToolyMcgee » 8 Apr 2009 10:26

Great idea. I know I've seen it before, but the emphasis on the 3 and 12 o'clock wrench actually made it stick with me this time. The Medeco was a nice touch too.  I've been using different flat wrenches to save space in small cases, but there is of course no room for a lateral tipped tensioner in a flat leather case you want to keep flat. This is working out great for more TOK options, and it doesn't bulge out the smallest case. They don't take up barely any room, so I can carry more wrenches. I have been carrying around a couple lengths of stainless steel rod in my kit for while. They don't make for very good picks, because they are so flexible, but they work nice for tensioners, and it only take 5 mins to fit one with a leatherman's file. I knew there was a reason I was lugging them around.  They were Mighty hook's. You know, one of those annoying commercials with Billy Mayes. They are large stainless drywall hooks you can pick up at most home improvement stores, and if you're lucky maybe the dollar store. Clip off the steeply bent end, and straighten the rest out for a wrench rod blank to keep with your other wrench blanks. Very handy. Thanks tballard. Good luck with that medeco. -Tooly *blank*

-

ToolyMcgee

-

- Posts: 640

- Joined: 27 May 2008 14:45

- Location: Indiana

by tballard » 8 Apr 2009 12:09 by tballard » 8 Apr 2009 12:09

ToolyMcgee wrote:They were Mighty hook's. You know, one of those annoying commercials with Billy Mayes. They are large stainless drywall hooks you can pick up at most home improvement stores, and if you're lucky maybe the dollar store. Clip off the steeply bent end, and straighten the rest out for a wrench rod blank to keep with your other wrench blanks. Very handy.

Interesting, I'll have to try those out. I've got a metal supply house near me which will sell me small quantities of almost anything, so I think I may be trying 1/8" and 3/32" stainless next. ToolyMcgee wrote:Thanks tballard. Good luck with that medeco.

Actually, with my latest t-bar, I'm able to pick it fully pinned now. (3 mushrooms, still no sidebar, but that's what the Medecoder is for, and once I am confident I can pick the shear dependably, I hope to be able to beat it at full strength)

-

tballard

-

- Posts: 225

- Joined: 29 Dec 2008 21:14

- Location: Austin, TX

by yanksfan » 22 Apr 2009 14:07 by yanksfan » 22 Apr 2009 14:07

I have to agree, I think the tension wrench/tool is more important than the pick itself (Actually it kind of depends on the lock, but in general..). Honestly about 75% of problems I come by when picking have to do with tension in some way, shape or form. Just my two cents  They call me Mickey G.

-

yanksfan

-

- Posts: 113

- Joined: 24 Jan 2008 17:05

- Location: Illinois

by urabusrpie » 27 Apr 2009 15:10 by urabusrpie » 27 Apr 2009 15:10

Yep, there isn't a whole lot of difference between HPC, ESP and Majestic hooks picks, for example...but there is a world of difference between HPC "Heavy" (Rigid) turning tools and LAB turning tools and everything else that is commonly available... Falle-Safe notwithstanding.

-

urabusrpie

-

- Posts: 7

- Joined: 25 Apr 2009 22:59

Return to Lock Picking 101 - FAQs, Tutorials, and General Information

Who is online

Users browsing this forum: No registered users and 0 guests

|