I took a picture of it next to a standard Sargent mortise cylinder for size reference.

Because of the way I assemble this lock I decided not to go through the hassle of taking it apart to take pictures. (I didn't want to pry the cap off the top again

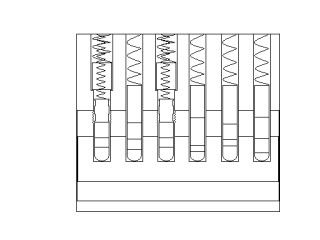

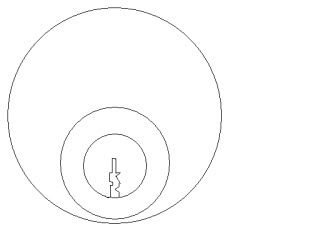

This is how the lock is normally, 6 pin chambers with two shear lines. Kind of like Best IC, ...without the interchangeable part.

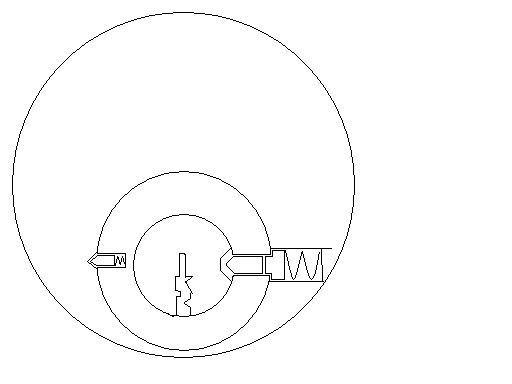

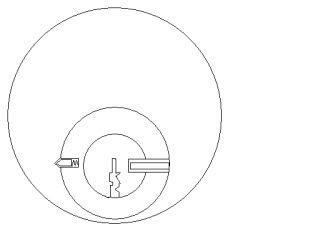

The temptation to make this lock extremely difficult to pick overwhelmed me. So the first thing I did was add a pin on the side to "loosely" lock the inner core and the master sleeve together. This made it so you had to pick the outer sleeve to get the lock to turn.

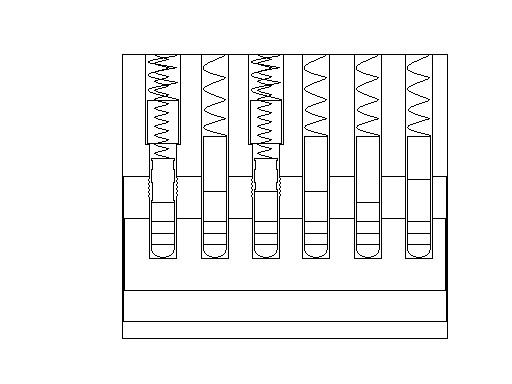

At this point it was very easy to pick the inner core, which will turn about 4-5 degrees and stop. And then if you didn't know better you would think that you made it to the spooled pins, halfway there, except all the pins are actually set to the bottom shear line!! Such a nasty little deceptive trick.

To make matters worse, or better (pending on how you look at it), I added a side bar to the outer sleeve. This sidebar has nothing directly related to the key. It serves one purpose. To prevent the outer sleeve from binding without first applying even more tension to the inner core, which can't turn.

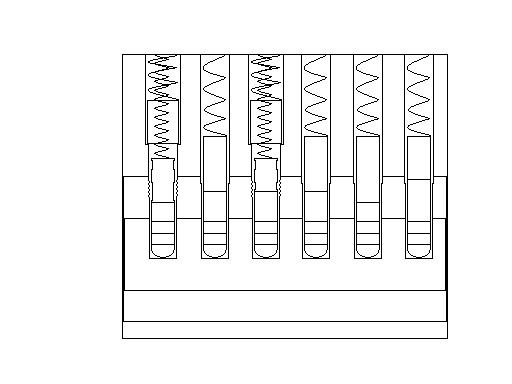

If I only wanted to deter single pin picking this would likely be enough. But ...well...yeah.

I modified two chambers so they couldn't be pick gunned/key bumped. I also made sure that every chamber can be picked and set at 3 different depths, only one of which is correct.