|

Information about locks themselves. Questions, tips and lock diagram information should be posted here.

by MacGyver101 » 20 Nov 2010 14:39 by MacGyver101 » 20 Nov 2010 14:39

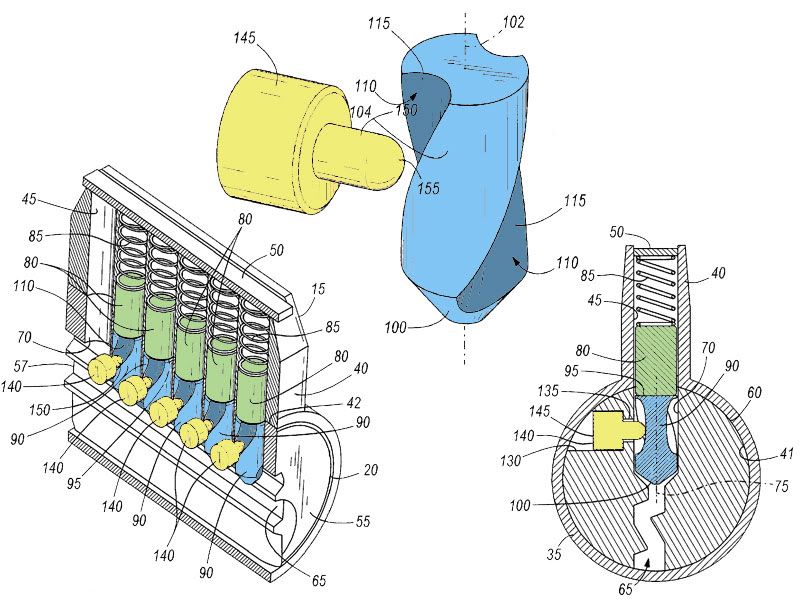

I ran across a new patent application today from Schlage ( 2009/0282881), that includes an interesting approach to making an anti-bumping pin. They're proposing to mill a spiral groove into the bottom pins, and have a second pin in a side chamber that protrudes into that groove: The side pin doesn't actually participate in locking the cylinder: it's simply there to force the bottom pin to twist as it lifts -- the idea being that you can't rapidly bounce it up with a pick-gun or bump-key. (The tips of the bottom pins aren't chiseled, so the "twist and lift" approach is just there as an anti-bump feature, rather than being a way to interact with a sidebar, like in a Medeco.) Interesting idea.

-

MacGyver101

- Moderator Emeritus

-

- Posts: 1560

- Joined: 21 Jun 2006 14:40

- Location: Toronto, Canada

by femurat » 20 Nov 2010 16:28 by femurat » 20 Nov 2010 16:28

Nice find MacGyver101, it's a very interesting idea! One of these anti bump pins, in the last chamber to reduce wear, could be enough for an anti bump effect. Now I'm wondering when (and if) Schlage will start producing it. Cheers

-

femurat

- Site Admin

-

- Posts: 3757

- Joined: 22 Sep 2008 9:06

- Location: Italy

by lunchb0x » 20 Nov 2010 22:38 by lunchb0x » 20 Nov 2010 22:38

This looks like a really good idea. I don't understand why company's are trying to make bump proof technology when it already exists though, like with the Emhart interlocking pins, can't bump them and picking will be hard. Not only that if you did pick it there will be evidence of this ad the pins wont interlock again.

-

lunchb0x

- Supporter

-

- Posts: 1227

- Joined: 25 Nov 2006 12:10

- Location: Australia

by MacGnG1 » 20 Nov 2010 22:43 by MacGnG1 » 20 Nov 2010 22:43

So would they just put one or two in the cylinder, like they do with security pins or every pin in the cylinder???

Nibbler: The poop-eradication is but one aspect of your importance.

-

MacGnG1

- Supporter

-

- Posts: 1362

- Joined: 9 Apr 2008 22:14

- Location: Know Where, MD, USA

-

by lunchb0x » 20 Nov 2010 22:48 by lunchb0x » 20 Nov 2010 22:48

MacGnG1 wrote:So would they just put one or two in the cylinder, like they do with security pins or every pin in the cylinder???

If this is refering to my post the interlocking pins are in every spacing, the key has angled cuts to align the pins so when at the correct height and angle the top and bottom pin can unlock from each other. To stop the top pins from turning around when the cylinder is unlocked the pin sits in a grove in the plug, this way it all lines up. Emharts from memory was sued my Medeco for using the pin twisting idea even though there is no side bar. I do have one here somewhere if you want pictures of the interlocking pins??

-

lunchb0x

- Supporter

-

- Posts: 1227

- Joined: 25 Nov 2006 12:10

- Location: Australia

by mh » 21 Nov 2010 2:34 by mh » 21 Nov 2010 2:34

lunchb0x wrote:This looks like a really good idea. I don't understand why company's are trying to make bump proof technology when it already exists though, like with the Emhart interlocking pins, can't bump them and picking will be hard. Not only that if you did pick it there will be evidence of this ad the pins wont interlock again.

Emhart was nice, no question, but are you suggesting every lock should use an Emhart pin and the two cuts in the key associated with it, one of them angled? I guess there's indeed room in the world of locks for other designs, too  Cheers mh "The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2440

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by femurat » 21 Nov 2010 3:20 by femurat » 21 Nov 2010 3:20

Hi MacGnG1, I said "one chamber" but it was just an idea of mine: this design works with just one pin, so why overkill by using all chambers? But I know nothing about Schlage future strategy. Cheers

-

femurat

- Site Admin

-

- Posts: 3757

- Joined: 22 Sep 2008 9:06

- Location: Italy

by lunchb0x » 21 Nov 2010 5:31 by lunchb0x » 21 Nov 2010 5:31

mh wrote:lunchb0x wrote:This looks like a really good idea. I don't understand why company's are trying to make bump proof technology when it already exists though, like with the Emhart interlocking pins, can't bump them and picking will be hard. Not only that if you did pick it there will be evidence of this ad the pins wont interlock again.

Emhart was nice, no question, but are you suggesting every lock should use an Emhart pin and the two cuts in the key associated with it, one of them angled? I guess there's indeed room in the world of locks for other designs, too  Cheers mh

No, not saying that every lock should have an interlocking pin in it, and making interlocking pins I think will be easier to make than something like this design there for also keeping costs down. two cuts in the key? do you mean 2 cuts for each cut on the key because the Emhart cylinders that I have are only 1 cut same as a Medeco cylinder. I guess I didn't really mean what I said before about "I don't understand why company's are trying to make bump proof technology when it already exists though", without people putting their ideas out there such as this there would be no advancements in anything, but there are already simple designs out there that could be used in domestic applications instead of lock company's misleading their customers with their "bump proof" technology which opens the lock up to other simple attacks.

-

lunchb0x

- Supporter

-

- Posts: 1227

- Joined: 25 Nov 2006 12:10

- Location: Australia

by mh » 21 Nov 2010 7:27 by mh » 21 Nov 2010 7:27

"The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2440

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by Solomon » 21 Nov 2010 7:29 by Solomon » 21 Nov 2010 7:29

Neat idea... one thing though, the key pins would need a bit more energy to move because of how they twist so wouldn't this actually make it easier to bump open? What I'm thinking is that the energy would be transferred to the drivers more effectively, since the key pins need more energy to move... ie. the drivers jump faster than the key pins, making the shear line even bigger. That's assuming these pins are present in all chambers anyway... as for having just a couple, I think that'd basically just be the equivalent of bumping a cylinder with hi-lo pin stacks, which is harder, but definately not impossible. Correct me if I'm wrong here cos my physics isn't always the best

-

Solomon

-

- Posts: 1012

- Joined: 9 Jan 2009 14:51

- Location: Northern Ireland

by illusion » 21 Nov 2010 11:34 by illusion » 21 Nov 2010 11:34

Great idea, I like the twisted pins. I wonder whether having a cylinder filled with these twisting pins might make the key difficult to insert and withdraw from the cylinder? I am aware it works doesn't impede the process when used in Medeco locks, however Medeco cylinders don't have a 'screw' action for the pins to undergo. Suspect 3 pins per lock will be like this in implementation to counter this, if this is the case.

-

illusion

-

- Posts: 4567

- Joined: 2 Sep 2005 13:47

by mcm757207 » 21 Nov 2010 14:38 by mcm757207 » 21 Nov 2010 14:38

I agree with Solomon... I feel that these twisting bottom pins would not be an efficient deterrent for bumping. Remember that the theory of bumping is that the bottom pins actually don't move very much, if at all. I also see the potential for attacks similar to the Michaud attack ( http://www.crypto.com/photos/misc/mul-t-lock/) or simplified Falle-style shim decoding. Emhart is one of my favorite high security locks, however it didn't stand the test of time. The cylinders have many problems and wear poorly (the fragile dove tails break). There are also problems with logical attacks due to the rules of keying up Emhart systems.

-

mcm757207

-

- Posts: 1468

- Joined: 12 Jan 2004 22:02

by sfi72 » 21 Nov 2010 17:01 by sfi72 » 21 Nov 2010 17:01

use groove to probe pin size?.......thin wire + modified sc1 blank and i think(if they use them in all their cylinders) we could rapidly decode these very easily.

<jkthecjer> this kwikset did not yield so easily

-

sfi72

-

- Posts: 236

- Joined: 17 Nov 2008 18:12

by Raymond » 21 Nov 2010 23:50 by Raymond » 21 Nov 2010 23:50

This is indeed an interesting find. Did the patent info state specifically that it was for bump prevention? I wonder if bumping would still be just as easy. With the top pin in contact with the bottom pin, the impact on the bottom pin would be likely to create a separation. It might make the separation between top and bottom pins even more because the bottom pin would be less likely to have moved much. The comparative example of two billiard balls touching when the cue ball strikes them comes to mind. The first ball remains stationery and transmits all the kinetic energy to the second ball which then moves away with almost the same velocity as the cue ball.

If this concept had a sidebar and the spiral groove had a valley or hole for the sidebar pin to fit into it would be pretty difficult to pick.

Nothing is foolproof to a talented fool. Wisdom is not just in determining how to do something, but also includes determining whether it should be done at all.

-

Raymond

-

- Posts: 1376

- Joined: 18 Jan 2004 23:34

- Location: Far West Texas

by MacGyver101 » 22 Nov 2010 2:34 by MacGyver101 » 22 Nov 2010 2:34

Raymond wrote:Did the patent info state specifically that it was for bump prevention?

I'm viewing it with the same degree of skepticism as everyone else, but that is their claim: In a conventional lock, relatively quick movement of the inner pins could be caused by bumping the inner pins with an improper or inappropriate key (not shown) in an attempt to pick the lock. In [this] lock cylinder, the [side pins] limit or resist movement of the inner pins [vertically] when the inner pins are bumped. [...] As a result, relatively quick movement of the inner pin is inhibited, [and] the outer pin remains partially disposed in the inner pin chamber, and the plug cannot be rotated to the unlocked position. I agree with the point about the pool balls, but I think what they're trying to do is to limit the amount of force the bump-key can apply to the drivers, by making the bottom pins harder to raise. I'm in need of a coffee at the moment -- so I may not be quite thinking of this correctly -- but I think the "pool ball" analogy works better with a pick-gun than with a bump-key. A bump-key works by sliding its tiny "teeth" underneath the bottom pins, in order to quickly raise and drop them. If you can't quickly raise the bottom pins, then (I think?) the bump-key's teeth are going to "catch" on the bottom pins, and far more of the bump hammer's energy will be directed back ( i.e., in the direction that the key's moving), rather than upwards and into the drivers? (This differs from a pick-gun, which isn't trying to translate the "horizontal" motion into a "vertical" one.) Either way, I like mcm757207's suggestion of a Michaud-like attack, if the grooves actually run right down to the bottom of the pin (which they do in the patent diagrams). Nice idea!

-

MacGyver101

- Moderator Emeritus

-

- Posts: 1560

- Joined: 21 Jun 2006 14:40

- Location: Toronto, Canada

Return to Locks

Who is online

Users browsing this forum: No registered users and 4 guests

|