|

TOSL Project. A community project to "build a better mousetrap".

by xBMW M3 GTR » 21 Nov 2010 21:45 by xBMW M3 GTR » 21 Nov 2010 21:45

vov35 wrote:@MH

there's only one shear line.

Watch the video I posted earlier. My lock design has 2 shear lines. "Did you bring your picky sticks with you?"

-Uncle Benito

Thanks to you I can't stop calling them that -_-

-

xBMW M3 GTR

-

- Posts: 73

- Joined: 29 Aug 2010 23:45

- Location: Detroit Michigan

by FarmerFreak » 21 Nov 2010 23:35 by FarmerFreak » 21 Nov 2010 23:35

xBMW M3 GTR wrote:mh wrote:Again, I believe that when the other pin stacks are set correctly to the inner shear line, their driver pins will block the outer shell from rotation, and nothing will turn until all pin stacks are set correctly.

The trap pins will not engage.

Looking into it right now, but having a little trouble understanding exactly how the design wouldnt work

mh is right, the driver pin would block the rotation of the outer shell unless all the pins were set to the outer shear line. Not just one, but all of them. This would likely work very well against impressioning techniques. Something to keep in mind though. Most picking attempts (at least the way I pick) start from the bottom up. Meaning the first shear line I would be setting the pins to would be the inner one, ..the correct one. Another thing to think about is that (assuming a 0 is the shallowest depth and a 9 is the deepest. and that the difference in the shear lines is 3 depths) the 0,1, and 2 depths will never be used. As they wouldn't allow for trap pins to ever be activated unless someone tried to pick it to a -3,-2, or the -1 respective depths. I hope that makes sense.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by FarmerFreak » 21 Nov 2010 23:47 by FarmerFreak » 21 Nov 2010 23:47

FarmerFreak wrote:mh is right, the driver pin would block the rotation of the outer shell unless all the pins were set to the outer shear line. Not just one, but all of them.

Unless you have the outer shear line sectioned into (assuming it's a 6 pin lock) 6 pieces, one for each chamber. Then you could set 5 to the correct shear line and even having the one off, it would lock up the inner core because the trap pins goes through both sets of shear lines. But if the outer shear line core is one piece, mh is right. Maybe you mentioned that earlier and I didn't see it.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by mh » 22 Nov 2010 2:17 by mh » 22 Nov 2010 2:17

Yes that makes sense, 6 outer rings and then one could be turned separately and trap. That's what I like about this team collaboration concept  "The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by mh » 22 Nov 2010 3:05 by mh » 22 Nov 2010 3:05

Also, maybe leave out the "trap" function and just let the outer rings stop at e.g. +/-30degrees.

That would make it some kind of "commit, then authenticate" concept:

The wrong key (or picked positions) would make the plug turn only 30 degrees; then one could ideally not find out why (which position is incorrect) and would have to turn the plug back and try again.

The problem I see (at least with the U.S. way of mounting locks) is that the pins would simply fall back down and then the outer rings are not engaged anymore.

I guess the same would be the case for the "trap" concept: Let the plug turn a little bit, then let the pins fall down, then probably only the inner plug turns freely and the outer rings stay where they are (untrapped).

Cheers

mh

"The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by xBMW M3 GTR » 22 Nov 2010 15:22 by xBMW M3 GTR » 22 Nov 2010 15:22

Okay guys, now im starting to get why this idea may not work...do you think this could be fixed through changing the size of the pins or thickness of the outer plug or any other small changes, or will the whole thing have to be ditched and redesigned?

"Did you bring your picky sticks with you?"

-Uncle Benito

Thanks to you I can't stop calling them that -_-

-

xBMW M3 GTR

-

- Posts: 73

- Joined: 29 Aug 2010 23:45

- Location: Detroit Michigan

by FarmerFreak » 22 Nov 2010 19:25 by FarmerFreak » 22 Nov 2010 19:25

xBMW M3 GTR wrote:Okay guys, now im starting to get why this idea may not work...do you think this could be fixed through changing the size of the pins or thickness of the outer plug or any other small changes, or will the whole thing have to be ditched and redesigned?

And here I was just thinking about how interesting this lock is getting... Okay, here is what I've come up with to compliment your lock concept. Under the premise that we are trying to completely lock up the cylinder if the wrong combination is tried. As noted earlier, have the outer core sectioned. One section per pin chamber. Now to add to that idea, it would be nice to have the shear line random per chamber. In other words, some chambers will have to be set to the top shear line and some will have to be set to the bottom shear line. So how would that be accomplished? Instead of having all the trap pins come in from the housing, you could have a few of them come from the inner core. The ones that come out of the inner core wouldn't need to be very long since they would only need to lock the inner core to the outer core. Since outer core will be locked in place by the regular driver pin. ...Now I think we're on to something!!

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by vov35 » 22 Nov 2010 19:34 by vov35 » 22 Nov 2010 19:34

Okay, say if we were to have the plug inside a hollow cylinder, but now we're using wafers, and with the correct key/correct sets, you'll only apply torque to the plug, but if not everything is correct, the wafers will either resist turning or turn this outer cylinder. You could have a trap pin fall through that and lock up both the plug and this cylinder to prevent lock rotation in the even of picking.

(same concept more or less though)

The BiLock isn't the first bump proof pin tumbler because it isn't a pin tumbler.

And it's called a shear line, not a "sheerline".

-

vov35

-

- Posts: 229

- Joined: 29 Sep 2010 15:13

by vov35 » 22 Nov 2010 19:45 by vov35 » 22 Nov 2010 19:45

of course you'd need to figure out some way to make sure the friction of the outer cylinder is slightly higher than that of the plug to avoid inadvertently activating the trap pin...

Such a design would resist impressioning pretty well, as well as jigglers, half cut keys, etc.

The drawback I'd imagine is that any imperfections in a key cut could be a serious problem.

The BiLock isn't the first bump proof pin tumbler because it isn't a pin tumbler.

And it's called a shear line, not a "sheerline".

-

vov35

-

- Posts: 229

- Joined: 29 Sep 2010 15:13

by xBMW M3 GTR » 23 Nov 2010 14:56 by xBMW M3 GTR » 23 Nov 2010 14:56

FarmerFreak wrote:xBMW M3 GTR wrote:Okay guys, now im starting to get why this idea may not work...do you think this could be fixed through changing the size of the pins or thickness of the outer plug or any other small changes, or will the whole thing have to be ditched and redesigned?

And here I was just thinking about how interesting this lock is getting... Okay, here is what I've come up with to compliment your lock concept. Under the premise that we are trying to completely lock up the cylinder if the wrong combination is tried. As noted earlier, have the outer core sectioned. One section per pin chamber. Now to add to that idea, it would be nice to have the shear line random per chamber. In other words, some chambers will have to be set to the top shear line and some will have to be set to the bottom shear line. So how would that be accomplished? Instead of having all the trap pins come in from the housing, you could have a few of them come from the inner core. The ones that come out of the inner core wouldn't need to be very long since they would only need to lock the inner core to the outer core. Since outer core will be locked in place by the regular driver pin. ...Now I think we're on to something!!

I'm having a little trouble picturing how it would work exactly although I do think I understand what you're saying. Do you mind making a quick sketch of it in MS paint or something just as a reference example? "Did you bring your picky sticks with you?"

-Uncle Benito

Thanks to you I can't stop calling them that -_-

-

xBMW M3 GTR

-

- Posts: 73

- Joined: 29 Aug 2010 23:45

- Location: Detroit Michigan

by xBMW M3 GTR » 23 Nov 2010 19:39 by xBMW M3 GTR » 23 Nov 2010 19:39

Alright, so I went back to the drawing board (literally) and thought of an idea. I'm still working out exactly how it could be accomplished and the proper mechanism to use...but heres my proposal.

Think of a lock with a normal trap pin setup. Now lets say those trap pins struck a mechanism on their way down, or even let off a spring to push a latching mechanism or large pin into an separate cut trap chamber to jam the plug from another area of the plug. The picker would think, "oh okay trap pins, I'll go pick em". The trap pins could all be picked to the shear line, but the jam would not allow the plug to turn. Security trap pins would not be needed since the jam pin (or whatever will jam the plug from turning) would not allow the plug to rotate either way. With this design, a double shear line design would not be needed.

Simply put, trap pins engage like normal and set off a spring loaded latching mechanism to jam the plug from another trap chamber.

I am also having some thoughts as to keeping the double shear line design (with some changes in design without the need for more shear lines) but making it work with the previously mentioned idea to possibly make picking much more difficult to help keep the picker from picking the lock to set the trap off. I know its probably not too likely more than one person would try and get into a lock by means of picking, but just in case, I know the lock owner would not want to go through lock disassembly and rebuilding (or calling a locksmith to do it for them if they aren't familiar with working on even a basic lock like many people) more than once (or even once for that matter), so we make the lock harder to pick so it lowers the chance of having the trap setting. If the picker manages to pick the difficult lock, the trap will back up security.

"Did you bring your picky sticks with you?"

-Uncle Benito

Thanks to you I can't stop calling them that -_-

-

xBMW M3 GTR

-

- Posts: 73

- Joined: 29 Aug 2010 23:45

- Location: Detroit Michigan

by FarmerFreak » 23 Nov 2010 19:40 by FarmerFreak » 23 Nov 2010 19:40

xBMW M3 GTR wrote:

I'm having a little trouble picturing how it would work exactly although I do think I understand what you're saying. Do you mind making a quick sketch of it in MS paint or something just as a reference example?

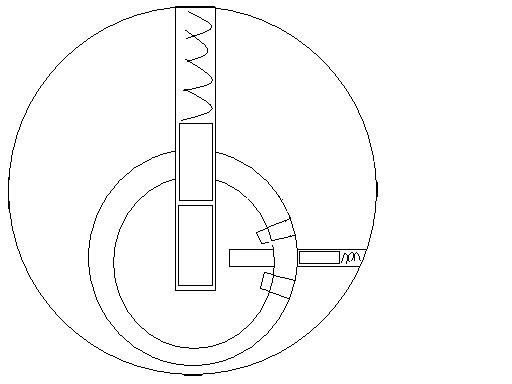

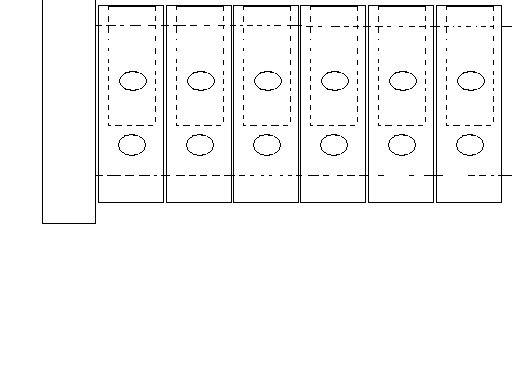

Sure thing, I uh, didn't spend a lot of time on these. And I didn't bother drawing the serrated pins. This top picture is basically your set up. If it is turned on the bottom shear line it will turn freely and won't lock up. But will lock up if the outer sleeve gets turned.  To change the shear line so now the top shear line is the correct one we simply need to put a trap pin (shorter in length) into the plug and leave the one in the housing out. With this set up, if the plug turned without the outer sleeve, the trap pin will lock the plug to the outer sleeve, which would be held in place by the regular driver pin at that point.  This next picture shows that there are 6 of these outer sleeves, one per pin chamber.  mh, if this were to be set up slightly differently and not set up to permanently lock up the plug/sleeves. I believe it could be set up as a basic commit then authenticate system.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by FarmerFreak » 23 Nov 2010 19:44 by FarmerFreak » 23 Nov 2010 19:44

xBMW M3 GTR wrote:Think of a lock with a normal trap pin setup. Now lets say those trap pins struck a mechanism on their way down, or even let off a spring to push a latching mechanism or large pin into an separate cut trap chamber to jam the plug from another area of the plug. The picker would think, "oh okay trap pins, I'll go pick em". The trap pins could all be picked to the shear line, but the jam would not allow the plug to turn. Security trap pins would not be needed since the jam pin (or whatever will jam the plug from turning) would not allow the plug to rotate either way. With this design, a double shear line design would not be needed.

There is a poster on here, I believe it is Yono that made a trap pin modification like this. He used a trap pin for the trap pin.

-

FarmerFreak

-

- Posts: 737

- Joined: 21 Apr 2009 11:58

- Location: SLC, Utah

by xBMW M3 GTR » 23 Nov 2010 20:15 by xBMW M3 GTR » 23 Nov 2010 20:15

FarmerFreak wrote:xBMW M3 GTR wrote:Think of a lock with a normal trap pin setup. Now lets say those trap pins struck a mechanism on their way down, or even let off a spring to push a latching mechanism or large pin into an separate cut trap chamber to jam the plug from another area of the plug. The picker would think, "oh okay trap pins, I'll go pick em". The trap pins could all be picked to the shear line, but the jam would not allow the plug to turn. Security trap pins would not be needed since the jam pin (or whatever will jam the plug from turning) would not allow the plug to rotate either way. With this design, a double shear line design would not be needed.

There is a poster on here, I believe it is Yono that made a trap pin modification like this. He used a trap pin for the trap pin.

Mine isn't too much like that design, although from the looks of it, I like the idea. Mine is more along the lines of the trap pins striking or releasing a mechanism to cause a trap pin or something else to fall into a chamber not accessible by picks in order to jam the lock. (just like my original design did) "Did you bring your picky sticks with you?"

-Uncle Benito

Thanks to you I can't stop calling them that -_-

-

xBMW M3 GTR

-

- Posts: 73

- Joined: 29 Aug 2010 23:45

- Location: Detroit Michigan

Return to The Open Source Lock

Who is online

Users browsing this forum: No registered users and 2 guests

|