|

Information about locks themselves. Questions, tips and lock diagram information should be posted here.

by LockDocWa » 4 Oct 2012 19:14 by LockDocWa » 4 Oct 2012 19:14

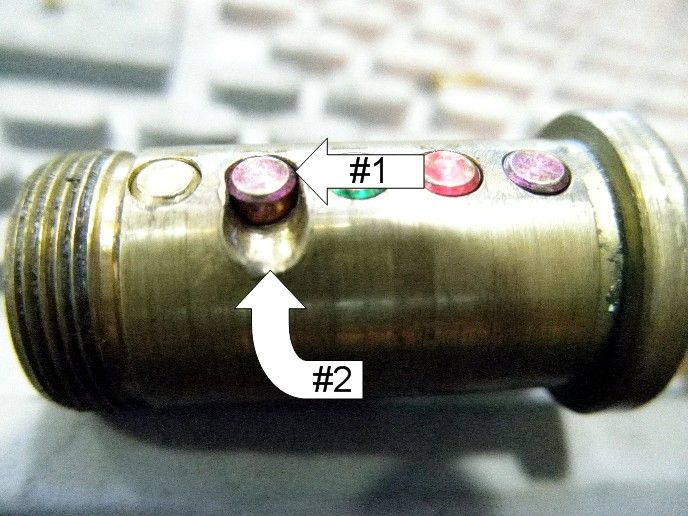

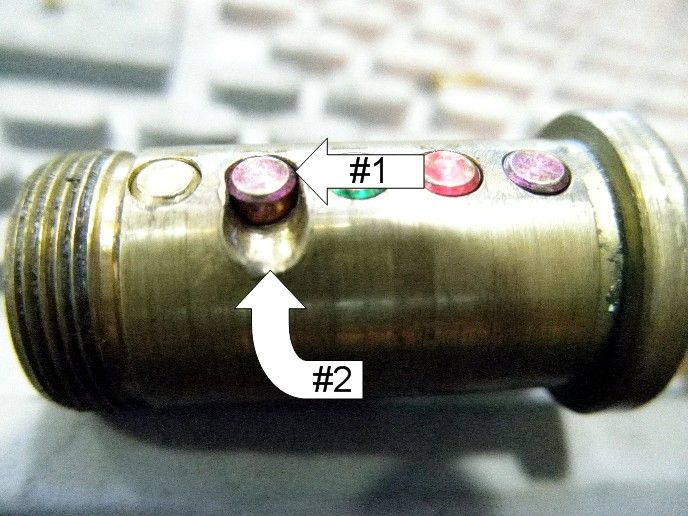

While rekeying a business today, I noticed this plug below. It appears to have 2 shear lines in one of the chambers. My only conclusion is, someone was trying to create a lock which when used with a key cut to shear line one, would turn the plug in either direction. When used with a key cut to shear line two, would allow you to turn the plug in one direction only. I guess an employee would get a key which only locks this door, and owner gets the key that locks and unlocks this door.  Ever seen this before?? Have you ever implemented this strategy??

-

LockDocWa

-

- Posts: 251

- Joined: 21 Sep 2012 9:54

- Location: Longview Washington U.S.A

-

by Josh66 » 4 Oct 2012 20:20 by Josh66 » 4 Oct 2012 20:20

I've seen a thread somewhere about that... It was done for exactly the reasons you came up with - one key can only lock it, the other key can lock or unlock it.

The one I saw had another pin that was cut in the other direction too - so it could have 3 keys: lock only, unlock only, lock and unlock.

-

Josh66

-

- Posts: 205

- Joined: 15 Jan 2012 20:31

- Location: Columbus, Ohio

by cledry » 4 Oct 2012 22:26 by cledry » 4 Oct 2012 22:26

It isn't common, but most locksmiths have used this at one time or another. It works and is simple and inexpensive. As was stated sometimes a second chamber will be modified the other direction. One key will allow employee A to open up and another key will allow employee B to close up, the boss will use a key that will operate normally.

Jim

-

cledry

-

- Posts: 2836

- Joined: 7 Mar 2009 23:29

- Location: Orlando

-

by Squelchtone » 4 Oct 2012 23:02 by Squelchtone » 4 Oct 2012 23:02

Josh66 wrote:I've seen a thread somewhere about that... It was done for exactly the reasons you came up with - one key can only lock it, the other key can lock or unlock it.

The one I saw had another pin that was cut in the other direction too - so it could have 3 keys: lock only, unlock only, lock and unlock.

This is probably the thread you saw, I just fixed the images in it as they were all missing due to the OPs server being offline. http://www.lockpicking101.com/viewtopic.php?f=9&t=15918I totally want to do this just to try it out... Squelchtone

-

Squelchtone

- Site Admin

-

- Posts: 11335

- Joined: 11 May 2006 0:41

- Location: right behind you.

by Josh66 » 5 Oct 2012 1:00 by Josh66 » 5 Oct 2012 1:00

^^^ Yeah, I'm pretty sure that was it.

-

Josh66

-

- Posts: 205

- Joined: 15 Jan 2012 20:31

- Location: Columbus, Ohio

by Raymond » 6 Oct 2012 0:18 by Raymond » 6 Oct 2012 0:18

Be very cautious using this type of alteration as it can lock you out. If the key that raises the pin to the original shear line height locks the door and then the user turns the key too far past the key removal position, the top pin can drop down into the filed out groove. The key can not be taken out and the lock cannot be opened because you can only turn it in the locking direction.

Nothing is foolproof to a talented fool. Wisdom is not just in determining how to do something, but also includes determining whether it should be done at all.

-

Raymond

-

- Posts: 1383

- Joined: 18 Jan 2004 23:34

- Location: Far West Texas

by Evan » 16 Oct 2012 15:42 by Evan » 16 Oct 2012 15:42

I know I am a little late chiming in on this thread, but in case anyone was curious, this type of cylinder is referred to as a "Brink's function" where one or two chambers are modified to allow for keys which can rotate one way or both ways to restrict access to the lock...

There are usually special relationships between the bittings used so as not to allow interchange between the keys or jamming the lock...

~~ Evan

-

Evan

-

- Posts: 1490

- Joined: 5 Apr 2010 17:09

- Location: Rhode Island

by GWiens2001 » 16 Oct 2012 16:36 by GWiens2001 » 16 Oct 2012 16:36

Evan,

If you (or anyone else here)happen to know, can you explain the relationship in the bittings for this 'Brinks' plug that prevents lockout? I have been tempted to try this out, as I have a large lot of mortice cylinders coming from eBay, so for the first time, will be able to perform this type of experiment.

I have seen the other threads, but don't see what can prevent lockout and stuck keys with this setup. (Excepting, of course, that I can drill, tap, and cap a cylinder for the trials.

Thanks,

Gordon

Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by Evan » 16 Oct 2012 17:20 by Evan » 16 Oct 2012 17:20

GWiens2001 wrote:Evan,

If you (or anyone else here)happen to know, can you explain the relationship in the bittings for this 'Brinks' plug that prevents lockout? I have been tempted to try this out, as I have a large lot of mortice cylinders coming from eBay, so for the first time, will be able to perform this type of experiment.

@GWiens2001: It all has to do with machining the "pocket" to the proper depth and then using bittings which never expose more than one shear line in the pocket at a time depending on which key is inserted... The example with which I am most familiar with is from Corbin Russwin and uses a pocket which is 0.028" in depth... The key which can rotate in both directions is the shallower bitted one, the deeper bitted one is the limited rotation key... The difference in bitting depths needs to be 0.056" (this is either 2 System 70 increments or 4 Pre-70 increments... The master pin used to accomplish the Brink's function keying is positively engaged by either the plug (for the non-limited key) or the shell (for the limited rotation key) so that no pins can become displaced or jammed in the lock... The master key operates at the true plug shear line and functions normally, the limited rotation key rides in the pocket and thus can only rotate in the direction of travel allowed by the pocket... ~~ Evan

-

Evan

-

- Posts: 1490

- Joined: 5 Apr 2010 17:09

- Location: Rhode Island

by Evan » 16 Oct 2012 17:31 by Evan » 16 Oct 2012 17:31

There is also a way to implement this Brink's function using no master pins, only I can not remember where I read about it, so I will have to do some searching around in the many reference books and OEM docs i have to find it...

~~ Evan

-

Evan

-

- Posts: 1490

- Joined: 5 Apr 2010 17:09

- Location: Rhode Island

by GWiens2001 » 16 Oct 2012 20:02 by GWiens2001 » 16 Oct 2012 20:02

I can understand how to make the keys work to either unlock or lock, but not how to make one key do both without the driver pin(s) dropping into the milled slots and creating a binding situation.

Except possibly using a flipped over short key pin and using it like a master wafer. Then having the master key bitting stepped between the machined shear line and the true shear line, allowing the flipped key pin to ride up the steps as if it were a key coming in from the side. Then the limited key would be cut deeper, to the milled shear line, preventing it from rising enough to turn to the unlocked position.

Does that sound do-able? Or is there another or better way?

Gordon

Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by GWiens2001 » 16 Oct 2012 20:04 by GWiens2001 » 16 Oct 2012 20:04

Guess would not need to be flipped.

Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by Evan » 16 Oct 2012 21:38 by Evan » 16 Oct 2012 21:38

Ok, after spending a couple of hours reading the various books and catalogs I have here is the deal with Brink function cylinders (also called Limited Control Key in the detention market)...

With the Brink function, a pocket of material is milled from the cylinder plug -- this part we all understand, which is sized for the difference between the two different key bittings... Only one bottom pin is used which is selected for the shallower master key bitting... The deeper change key with limited rotation automatically operates because the pocket is the correct depth for the difference and only allows rotation in one direction...

The example that Corbin-Russwin provides states that it can not be used where 360º rotation is required to operate the lock, specifically mentioned an application for use with an Adams Rite latch bolt unit with hold back feature where the tenants would have the change key (limited) and the landlord/management would have the master key to activate the latch hold back... You could also use such cylinders with a plain old classroom function mortise lock where the master key can both lock and unlock the unit and the limited key can only lock it...

With the LCK (Limited Control Key) the function is created using either a master ring cylinder or a Mogul cylinder with a master ring... (Master ring and Mogul are slightly different sizes, for reference: Standard Mortise cylinder = 1.366" diameter; Master Ring cylinder = 1.648" diameter and Mogul cylinder = 2.245" diameter...)

The limitation is imposed by a pin placed in the ring to block the motion of the cam and effects the use of change keys which are keyed to operate at the plug shear line... The master keys operate at the ring shear line and can rotate the full 360º because the pin is attached to the ring and moves with it...

The application of this is for use on minimum security heavy duty mortise locks used on prison cell doors where the inmate is issued the LCK for access to their cells from the outside when the deadbolt is unlocked as the outer lever is rigid at all times... The master key will project or retract the deadbolt as well as the latch so it can be used to secure the prisoners in the cell or to secure the cell from inmate access with the LCK change key from the outside when required... The lever inside the cell will retract the latch but not the deadbolt...

~~ Evan

-

Evan

-

- Posts: 1490

- Joined: 5 Apr 2010 17:09

- Location: Rhode Island

Return to Locks

Who is online

Users browsing this forum: No registered users and 8 guests

|