|

When it comes down to it there is nothing better than manual tools for your Lock pick Set, whether they be retail, homebrew, macgyver style. DIY'ers look here.

by jobefx » 31 Jan 2011 11:12 by jobefx » 31 Jan 2011 11:12

I recently picked up a Best I-core without keys at a flea market to practice picking. I tried to make a peterson style wrench using a bit of windshield wiper blade metal. But I still cant pick the lock. I think the problem is the wrench I made is not keeping the control sleeve thing tensioned properly, so I still have the 2 shear line problem to deal with. The control sleeve has not been slotted I can feel the holes in the lock but I still cant pick this thing.

So...

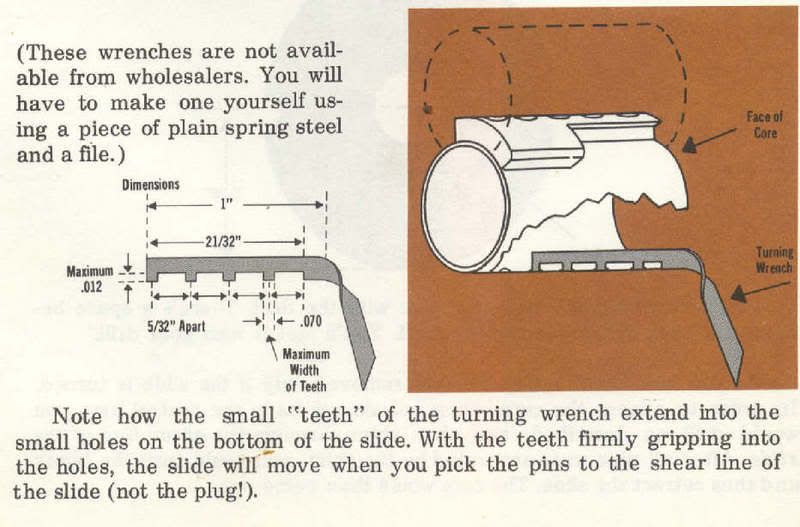

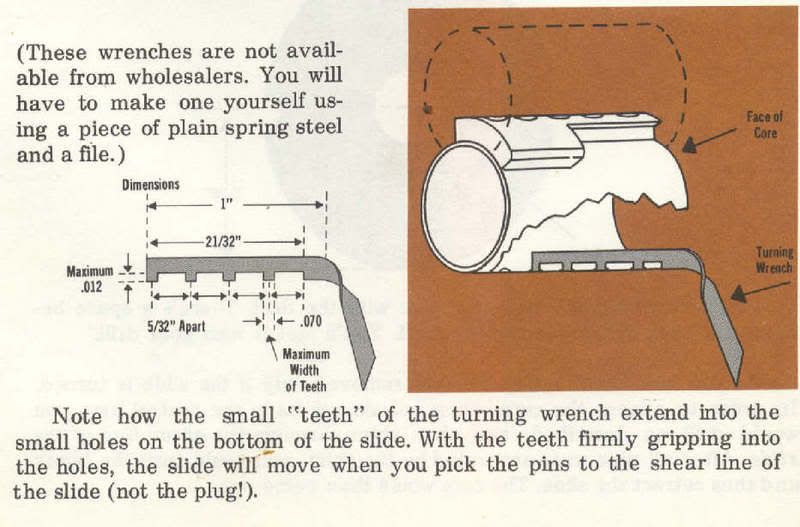

Does any one have a template for a wrench that works? Either that or can take measurements on a wrench that works. how deep are the teeth? how far apart are they? How big are the teeth? What are the dimensions of the wrench itself? The wiper blade wrench I made is a little too thin I think, it rolls way over in the keyway which may be why its not working properly.

Any help would be appreciated I am still a noob at this.

Thanks

-

jobefx

-

- Posts: 4

- Joined: 19 Jan 2011 12:44

by Storm » 31 Jan 2011 19:01 by Storm » 31 Jan 2011 19:01

Hi Jobefx,

I think you over analysing the issue.....the easiest way to approach this is with a file and metal strip. No 1 commercial tension wrench is a do all solution, in fact many of the top makers and designers supply just the metal and create a bespoke TW yourself. Even Peterson and Falle do this.... so take a step back a create a simple TW yourself, unsprung, untoothed and untapperd . Go back to basic and focus on as we call it in the UK, "operator error" get to know how much tension is right and how it feels to you. Once you have the hang of a bespoked , then you can start comparing that feeling whilst using a multi adjustable or toothed TW, which try to solve the one stop solution challenge. Best of luck and watch so of the videos on Utube, some of the guys here, teach it really well on those videos. Storm

-

Storm

-

- Posts: 44

- Joined: 17 Feb 2010 6:09

- Location: Windsor UK

by jobefx » 1 Feb 2011 12:10 by jobefx » 1 Feb 2011 12:10

Hey storm thanks for the the reply, I think I may not have been clear on what I am looking for. I have several different tension wrenches that work on a variety of locks, I am pretty good at normal locks. I picked up the Best SFIC I-core to challenge myself, its a seven pin lock and has a control sleeve to allow a control key to remove the core from the cylinder. The control sleeve makes the lock have 2 shear lines - 7 pins and no way to tell which shear line the pins are set to makes it pretty darn tough to get open. Matt Blaze wrote a great article on this type of lock http://www.crypto.com/photos/misc/sfic/What i am looking for is a template or the measurements of the tension wrench he uses in the article (fig 8 ). I know the tension wrench is made by peterson and I could order a set I just didn't want to shell out the money for them when it looks simple to make. If I could get my lock open I could measure the holes in the control sleeve and make the tension wrench teeth to fit, but with out the wrench I cant seem to the get dumb lock open. So I am stuck, any help making a wrench would be appreciated. thanks jobefx

-

jobefx

-

- Posts: 4

- Joined: 19 Jan 2011 12:44

by Wizer » 1 Feb 2011 13:12 by Wizer » 1 Feb 2011 13:12

Hi, A quick search in "Collection of templates"- posts gave this:  , posted by "muskratt" and appatently made by "joshuawilson" ...Search is your friend...

-

Wizer

-

- Posts: 687

- Joined: 13 Jun 2009 3:54

- Location: Finland

by jobefx » 1 Feb 2011 14:23 by jobefx » 1 Feb 2011 14:23

Thanks Wizer that's perfect. Sorry I did search.... I just didn't find. Found lots of interesting stuff about the lock itself though.

Thanks Again

-

jobefx

-

- Posts: 4

- Joined: 19 Jan 2011 12:44

by keysman » 2 Feb 2011 12:00 by keysman » 2 Feb 2011 12:00

I can't tell if you have just a core or if you have a lock of some type, with a core in it that you want to remove.

If you have the core in your hand, just measure the holes at the bottom of the keyway. That is where the tension wrench goes and will tension the control sleve.

If the core is in a lock of some type, I can send you a picture of a lock next to a ruler and you should be able to figure it out from there.

FYI the distance between cuts ( spacing) is .150 inches.

Everyone who eats potatoes eventually dies. Therefore potatoes are poisonous.

-

keysman

- Moderator Emeritus

-

- Posts: 1174

- Joined: 29 Dec 2004 5:09

- Location: Las Vegas,Nv.USA

-

by jobefx » 3 Feb 2011 12:10 by jobefx » 3 Feb 2011 12:10

The core is still in the cylinder so I couldn't take proper measurements. I bought the thing for a dollar at a flea market because it had no keys, so I am pretty sure the previous owner just unscrewed the cylinder from the door and tossed it.

now that I have measurements, I am still trying to find material that is a proper size width to make a wrench from. I made my first wrench from a wiper insert but after cutting the teeth in the wrench the wrench became too narrow to hold onto the keyway, it just kind of rolls over in the keyway with out grabbing onto anything.

thanks for everyones help I appreciate it.

-

jobefx

-

- Posts: 4

- Joined: 19 Jan 2011 12:44

by Jakoblivion » 22 Apr 2013 12:39 by Jakoblivion » 22 Apr 2013 12:39

For future reference to any newbs (like myself) looking into SFIC trying to make a homebrew Peterson's wrench, the holes in the control sleeve are in line the the pin stacks in the core itself. A quick search should find you that information as well, in a simpler manner  Or you could look at Keysman's wonderful post above! keysman wrote: FYI the distance between cuts ( spacing) is .150 inches.

Thank for that info, Keys. By the way, jobefx, not calling you a newb at all! Do not try to pick the spool, that would be impossible.

Instead, only try to realize the truth: There is no spool.

Then you'll see that it is not the spool that's picked, it is only yourself.

-

Jakoblivion

-

- Posts: 12

- Joined: 8 Feb 2013 13:02

by IndigoChild » 26 Apr 2013 19:54 by IndigoChild » 26 Apr 2013 19:54

I just ordered this set with the slender gem because we have a whole ton of "Special" IC cores in the shop right now and I am trying to pick them all to control which doesn't work that good with my tensor. I keep picking it to operation. So we will see what happens when they arrive.

"How does it work?"

"Only one way to find out. Open it up!"

-

IndigoChild

-

- Posts: 236

- Joined: 1 Feb 2013 13:50

by phrygianradar » 26 Apr 2013 20:51 by phrygianradar » 26 Apr 2013 20:51

IndigoChild wrote:I just ordered this set with the slender gem because we have a whole ton of "Special" IC cores in the shop right now and I am trying to pick them all to control which doesn't work that good with my tensor. I keep picking it to operation. So we will see what happens when they arrive.

Just a note on the subject of Peterson IC wrenches. I have found that they work really well for some locks (or pinnings) but not well at all for others. There is almost no way to tell if it will work or not except for just trying it out. I was trying to pick a 7-pin Best lock to control for about a week with no success. I ordered the wrench set and when they got there, I had it picked to control in about 5 minutes! That isn't always the case, but when they work, they really work. I just picked probably the hardest SFIC lock I have ever picked to date today (to control, of course). It is a 7-pin "InstaKey" SFIC that was in a mortice case. I have been working on it since Monday and just got it open a few minutes ago. This was one of those locks that it seemed my Peterson IC wrenches didn't work well on. I found out why when I pulled the core out. There are no holes to grip for the first four pins! Only the last three pins actually have holes on the bottom of the lug shell! That explained a lot. Have fun with your cores! I have to say, I am envious. Picking SFIC cores is probably one of my favorites type of locks to pick so far, just because they can be so challenging, even with the Peterson wrenches. Be sure to post your success and feedback on the wrenches. I really like them a lot, but again, they can be hit or miss. And be sure to shim them, that will really help, but is kind of hard to do at first (or at least it was for me  ).

-

phrygianradar

- Supporter

-

- Posts: 471

- Joined: 2 Feb 2013 0:57

- Location: San Diego, CA

by MrWizard » 26 Apr 2013 23:32 by MrWizard » 26 Apr 2013 23:32

I picked best and falcon IC long before there were any tension tools on the market. I had a teacher name G.L Finch that handed me a best mortise cyld never been picked by him. And told me how a tension wrench for it should be made. Not ever seeing one or knowing what I was doing took it home made the tension wrench as per instruction checking the depth of teeth gauged by the control sleeve by looking that the front of the cyld on the bottom. The tension wrench would slip out of the holes too easy so I thought to wedge another regular wrench on the left side of the ic one to lock it into position in a more straight up and done position. I had the lock picked at the control line in minutes after that. Took it back to school and handed it to him he was blown away! Asked how I was able to do that. I handed him the tension wrench and then showed him how I wedged it in the keyway. He said that is just amazing can you make me one for my IC core classes. I said you can have this one!  That was in back in 1978 he was the best locksmith teacher ever. He retired from teaching then and went to LAB to help them with their IC core products. He had a long 20+ year history working for military here and over seas teaching covert entry and how to protect against it from happening. Brilliant man sad to say he has passed away now I learned so much from him. Biggest mistake you can make trying to get a core picked at the control line is letting it slip out of the holes the teeth engage in as the more it slips out the more wear on the very thin control sleeve holes it makes and after a while you will never keep it in the holes. So try wedging another tension wrench as I said above to make it become one with the lock. You don't have to hold it in place it stays there by itself if done right.  Richard "Those who believe in telekinesis, raise my hand."

-

MrWizard

- In Memoriam

-

- Posts: 252

- Joined: 11 Oct 2012 12:21

- Location: Phoenix Arizona USA Planet Earth

by MrWizard » 26 Apr 2013 23:52 by MrWizard » 26 Apr 2013 23:52

I should correct the above and say Finch retired from teaching then went to Falcon to help them with the IC core products and kits then ended up working for LAB later.  Richard "Those who believe in telekinesis, raise my hand."

-

MrWizard

- In Memoriam

-

- Posts: 252

- Joined: 11 Oct 2012 12:21

- Location: Phoenix Arizona USA Planet Earth

Return to Lock Picks

Who is online

Users browsing this forum: No registered users and 2 guests

|