I began with the cheapest deadbolt I could find and took out the plug, pins, and springs. I clamped it down with a vise so the side of the bible was facing upward, toward the bit of the mill. I started with a small drill bit and just plunged down Into the bible, but not all the way through. Without moving the lock horizontally, I switched to the smallest end mill bit I could find (1/4" dia) and brought it down until it started cutting the surface of the bible (plunging with the tip of the end mill bit could damage it, which is why I plunged with the drill bit).

Since the material I was going through was tough, I went slowly and used a lot of cutting fluid. I'd do one pass, return, raise up the lock a small bit, and repeat. When I cut deep enough to see into the five places where the springs rest, I took out the lock and cleaned it off.

When I tried to load the pins back in, many of them got stuck, so I smoothed down the cuts I made with a dremel until the pins fit in. I then reassembled the lock, and I finally had my own cutaway.

With my first attempt, the side of the bible was not perfectly flat, leading to uneven cuts and the holes allowing me to see the springs and driver pins being too large. Some springs kept popping out, so I used epoxy to affix a small piece of acrylic to the bible.

Ugly, but it does the job.

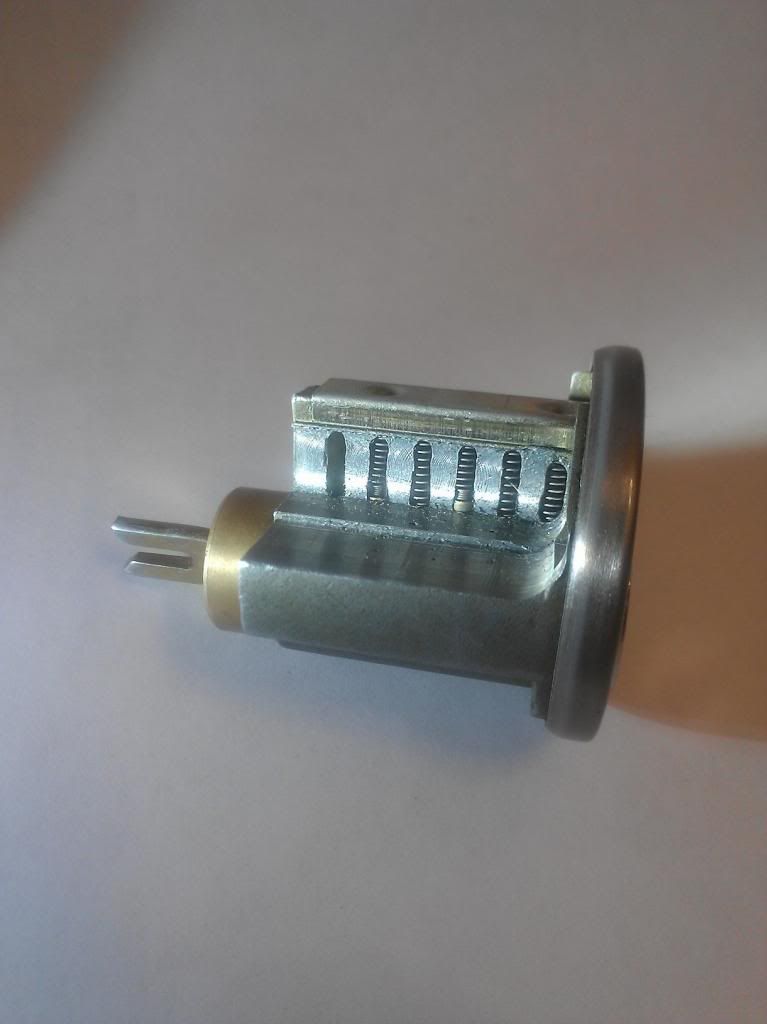

I tried the same method again, but this time I used a 5 pin Schlage deadbolt and was more careful to keep it level. I also stopped cutting with the mill earlier this time, since cutting creates a thin foil over the top of the cavities that is easily removed with a dremel. Basically, stop as soon as you can see into the pin cavities, since the holes will only get larger from here.

Much prettier!

With the key. Very useful for showing how pin tumbler locks work.

Making cutaways this way was pretty simple. All it requires is access to a machine shop and basic knowledge of tools. I'm pleased with how the second one came out, and it's helped me improve my picking skills a lot, since I'm able to double check if the pin I'm feeling is set, not set, or overset. I am curious to know how other people made theirs, especially ones where you can see the plug and key pins. Also, the next time I make a cutaway, I'll be sure to get pictures of the process. Hope this helps, and I'd love to hear your tips!