So this was my first milling project. I chose it because it involved drilling, using the rotary table, slotting...

Anyway, the idea was to add an 8th tine to my Southord pick. This gives it the ability to do 7 pin, 7 pin left (and right) offset and 8 pin. Also I added screws for each tine to control their tension individually and also to completely lock them down when necessary. Locking them down tight is something I have always wanted to do because tubular picks have the tendency for set tines to slip even when the collar is locked down 100%.

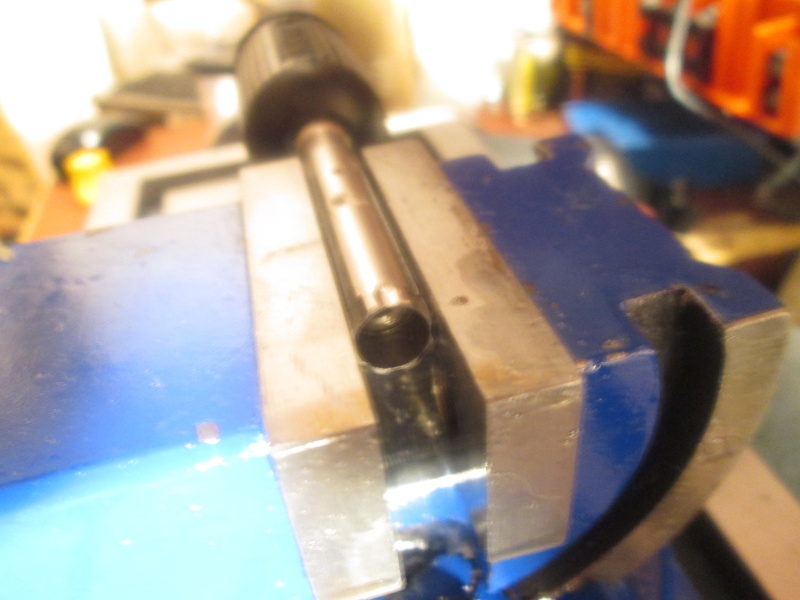

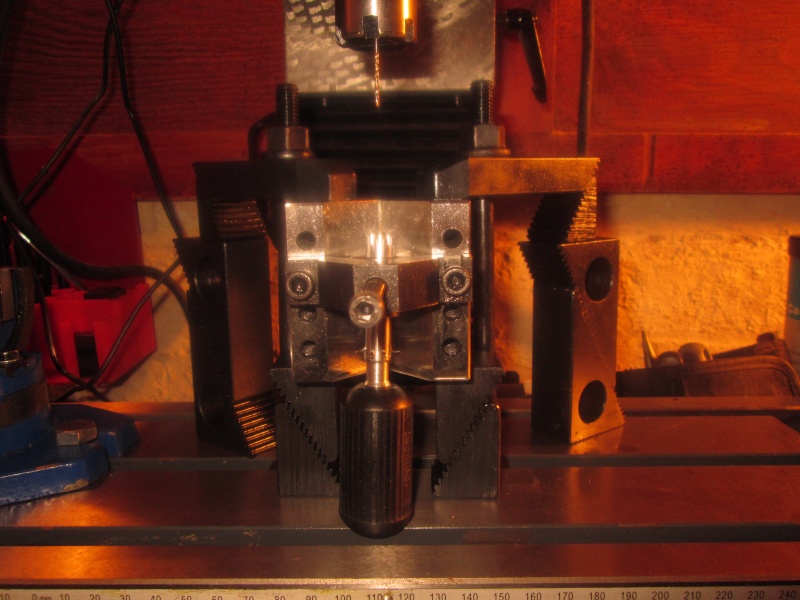

First operation. Drilling and tapping holes around the collar:

At first I had things set up badly and I got bad results so a few of the holes I did at first are ugly and not 100% straight. I also got a carbide drill bit stuck tight in one of the holes (which was a major PITA to get out) and a crap Rolson tap broke in another.

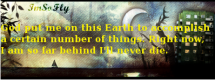

Anyway, I got them drilled but there was a problem. When a screw was tightened it pulled the collar up towards it and so ended up pinching the tine on the opposite side against the collar and trapping that one tight too. Like so:

So it meant I needed to mill little gaps from the inside of the collar so the pressure was relieved:

Fixed! :akimbo: Now I can play with any of the screws independently of affecting any other tines.

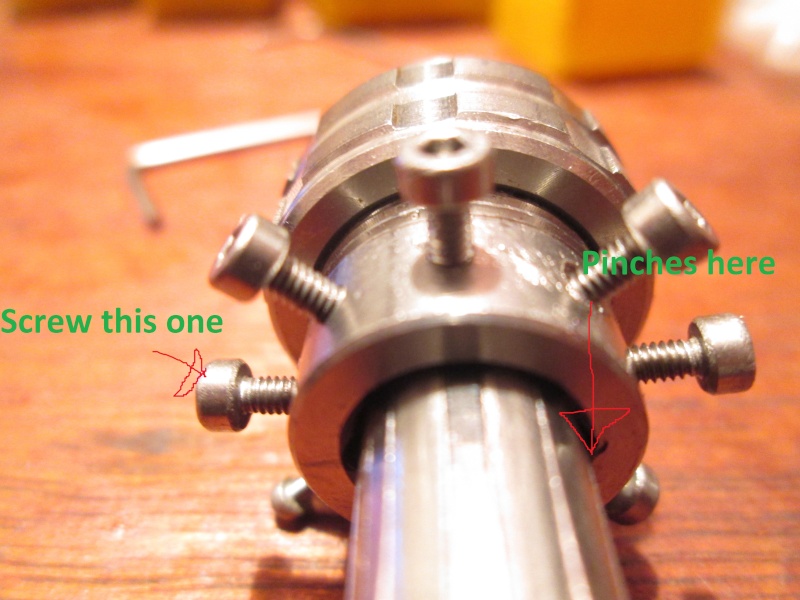

This left the new slot and pin cup left to be milled:

I also had to make a new tine. I did it from brass first but it was just too weak so I did it from steel shim. It's good but still not quite as strong as the ones that come with the pick. It is as thick so maybe it would benefit from heat treatment?

But does it work?

That is an 8 pin by the way.

Interesting thing regarding the position of the pins from a 7 to an 8 pin;

On a 7 pin, the roll pin (or, the 12 o' clock position) sits directly opposite where you imagine the 8th tine would go.

But on an 8 pin (or 7 pin offset), the pins are all rotated around 22.5 degrees. So the roll pin no longer site opposite a tine, it sits in the gap between them. You can see this on the picture below, this is an 8 pin lock in the locked position. Notice that all the pins are shifted round a little from a 7 pin. I suppose this is what makes them 'offset'!

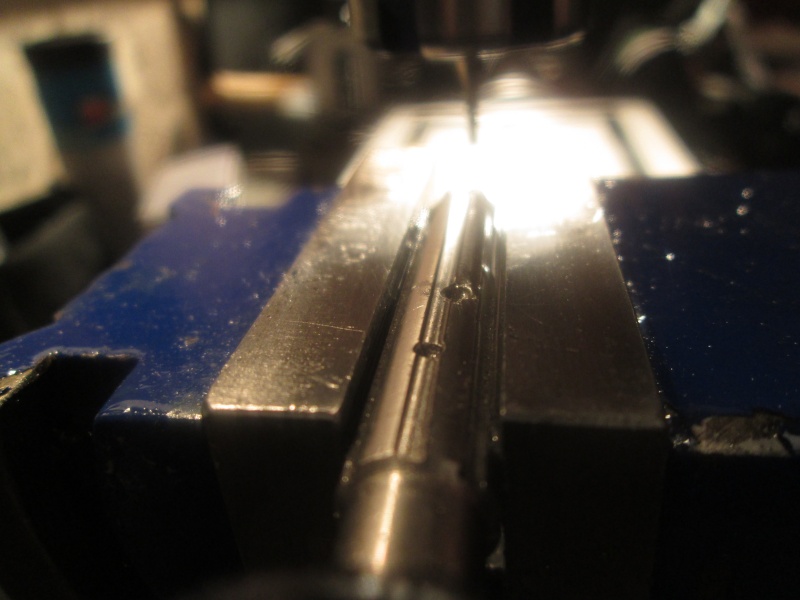

In practicality, you can remove the roll pin and move it to the new position for a non 7 pin standard but it works without the roll pin at all. In fact, the roll pin is never necessary, the pick would work just fine without ever using it. This is how I had to set up for the drilling of this 2nd roll pin location:

There HAS to be an easier way but that rubber handle does not grip well!

Onto the next project...