|

When it comes down to it there is nothing better than manual tools for your Lock pick Set, whether they be retail, homebrew, macgyver style. DIY'ers look here.

by YouLuckyFox » 12 Jun 2014 20:23 by YouLuckyFox » 12 Jun 2014 20:23

I am currently taking a CNC course as part of the Welding degree I am pursuing. One of the projects is to make something on a wire EDM. At first I was going to make a key fob with the LP101 logo and then donate it, but sadly it would be a bit too complicated for the time I have right now. I have instead decided to make a lockpick. I drew up the diagram today and will probably choose a Peterson Gem (at this point, anyways, any suggestions?) I'll probably use .002 stainless steel (301 - a spring steel,) but I'm not sure. The advantage of a wire EDM over an endmill is that an endmill (speaking for the tool) is generally going to only have so small of a diameter, but a wire EDM thread will have a diameter of less than a thousandth of an inch. So, really small and intricate patterns and designs can be made here, the only limit I am placing is that I don't want to have too many breaks in the profile, as I will need to center drill and re-thread several times. Also, pretty much any material can be used here, no matter how hard or soft, as long as it is electrically conductive, of course. Anyway, just wanted to make this thread to leave it open to suggestions on the pick profile and material (maybe .002 is too thin, etc.) I might actually be able to make an extra if anyone would be interested in paying shipping! - (PM if interested but no promises, I won't send unless I'm proud of it! Also, I won't make more than two picks or I'd be hogging the machine!) Any suggestions for designs or pick material?

-

YouLuckyFox

-

- Posts: 630

- Joined: 10 Aug 2012 19:25

by NinjaLlama » 19 Jun 2014 19:31 by NinjaLlama » 19 Jun 2014 19:31

I bet playing with an EDM is a blast. I would say that 0.002" is probably too thin to be a very robust pick.

-

NinjaLlama

- Supporter

-

- Posts: 51

- Joined: 9 Jul 2011 15:41

- Location: Oklahoma

by YouLuckyFox » 19 Jun 2014 22:58 by YouLuckyFox » 19 Jun 2014 22:58

Oh my bad, I meant to put .020" and just never changed it! Sorry, very poor form on my part.

-

YouLuckyFox

-

- Posts: 630

- Joined: 10 Aug 2012 19:25

by YouLuckyFox » 19 Jun 2014 23:01 by YouLuckyFox » 19 Jun 2014 23:01

Thank you for the comment, though. If I had meant 0.002" I would appreciate knowing that that was too thin. Yesterday I was thinking, "Fox, you know you put 0.002" instead of 0.020" right?" and I meant to change it but didn't get around to it. I'll try to post a screenshot of the design sometime this or next week hopefully. Once the material comes it will just be a matter of putting the code on the machine...

-

YouLuckyFox

-

- Posts: 630

- Joined: 10 Aug 2012 19:25

by NinjaLlama » 20 Jun 2014 6:01 by NinjaLlama » 20 Jun 2014 6:01

You could add a handle design or logo for extra fancyness.

-

NinjaLlama

- Supporter

-

- Posts: 51

- Joined: 9 Jul 2011 15:41

- Location: Oklahoma

by 1mrchristopher » 20 Jun 2014 9:01 by 1mrchristopher » 20 Jun 2014 9:01

I look forward to seeing your design, and your finished product. To put .002" into perspective, heavy duty aluminum foil is .00945" No worries about a slip of the finger, I just had to find a frame of reference for myself.  One of the keys to happiness is a bad memory - Rita Mae Brown

-

1mrchristopher

-

- Posts: 331

- Joined: 4 Mar 2014 0:32

- Location: Sidney, MT

-

by YouLuckyFox » 20 Jun 2014 18:02 by YouLuckyFox » 20 Jun 2014 18:02

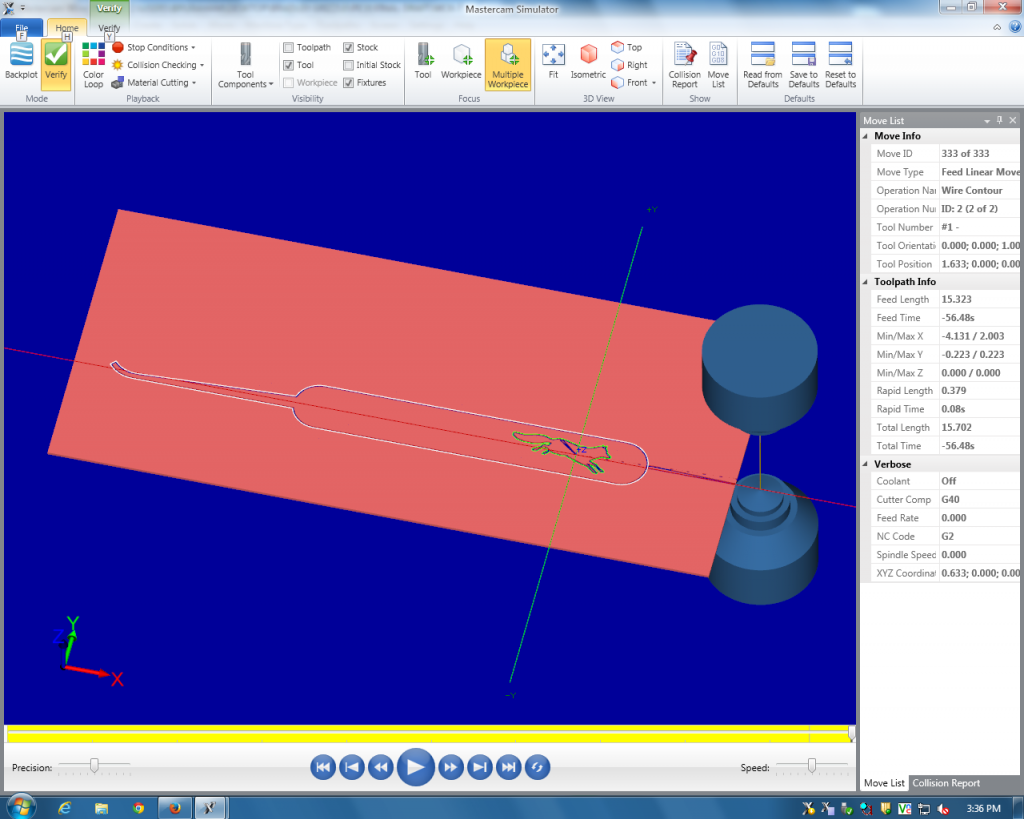

Here's what I've got so far, the dotted line there will not be cut.

-

YouLuckyFox

-

- Posts: 630

- Joined: 10 Aug 2012 19:25

by GWiens2001 » 20 Jun 2014 18:19 by GWiens2001 » 20 Jun 2014 18:19

Nice shape on that hook.  How many other picks do you plan in this project? Gordon Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by YouLuckyFox » 20 Jun 2014 23:40 by YouLuckyFox » 20 Jun 2014 23:40

Thanks, Gordon! So far just the one pick; if anyone has a neat design that takes advantage of the EDM machine (really small tolerances for a logo or really minute peaks on a bogota or something--you could use this to make a TINY bogota for instance, etc.) I would be most pleased to borrow that creativity and send it to the originator of the concept. For now, I'm just planning on making this design, and then--if I have time--taking a piece of 0.020" copper and cutting the same fox design, just slightly larger, and pressing it into the fox template on the pick  . That's all I have for now; again if anyone has any other suggestions, I am eager to listen! For anyone who wants to see about having me make them something, please PM and we can work something out (I'll only charge for shipping, of course, it takes very little effort to get the code for a part like this.) Limited to one other pick, as I don't want to hog the machine from other students.

-

YouLuckyFox

-

- Posts: 630

- Joined: 10 Aug 2012 19:25

by YouLuckyFox » 20 Jun 2014 23:43 by YouLuckyFox » 20 Jun 2014 23:43

*Oh, I forgot, I'd need to charge for both shipping and material costs^ Behold, the large print giveth, and the small print, taketh away

-

YouLuckyFox

-

- Posts: 630

- Joined: 10 Aug 2012 19:25

by 1mrchristopher » 23 Jun 2014 23:02 by 1mrchristopher » 23 Jun 2014 23:02

Nicely done! Now you should make a deForest to match  One of the keys to happiness is a bad memory - Rita Mae Brown

-

1mrchristopher

-

- Posts: 331

- Joined: 4 Mar 2014 0:32

- Location: Sidney, MT

-

by YouLuckyFox » 23 Jun 2014 23:35 by YouLuckyFox » 23 Jun 2014 23:35

I don't have really anything else planned after this, I've decided against press fitting a copper in-lay of the fox into the pick, mainly because it would be too finicky with such a thin part (plus getting the feet would be TOUGH!) The next projects are a lathe project, a nameplate with my sons name and a baby bottle etched in (using the end-mill) and a wood plane that is machined to 0.0001" tolerance (not a wooden plane, but a plane for carpentry work,) and I want to have as much time as possible on that wood plane! Now that I've done it once, I've learned I can stack several of these in one pass (up to a stack of over 4 inches!) to make a whole bunch of lock picks in one go. Anyway, here's my summary, hope this benefits someone:

Advantages:

You can stack these and do several profiles in one process

Extremely tight tolerances

No burrs whatsoever

Goes through anything that conducts electricity, being very helpful on hard to machine metals

Disadvantages:

Not a cool process to watch

Very slow, this part (speaking of the pick as a "part") took well over an hour to complete

Even as small of tolerances as this can do, the initial arc leaves a bit of "arc burn"; ideally this would be at the very center of a profile that would not be included, or the arc would start outside of the part (in this case a hole was drilled to start the wire at the center of the fox, but it still left a bit of arc burn--could have been fixed by more careful preparation work with setting up the fixture)

Because you are often only making one part, you don't take the time to set up a thoroughly locating and constraining fixture, which can cause accuracy to suffer.

For every contour you make, you must either start outside of the workpiece (so that the wire can thread and cut) or make a hole for the wire to thread through (this is why I ultimately decided against a key fob)

ALSO, any closed contours would obviously be cut out of the part, so a closed letter like an "O" would need to be especially designed to remain linked to the workpiece somewhere

A clarification on the original post in this thread:

I ultimately decided with 0.025" 301 Stainless Steel, I referred to it in my top post as "a spring steel" though 301 Stainless can be tempered to "spring," I did not mean to imply that any form of 301 would be spring-steel. 301 can be found in a range of hardnesses, but I did indeed order it in "spring" temper.

-

YouLuckyFox

-

- Posts: 630

- Joined: 10 Aug 2012 19:25

by GWiens2001 » 24 Jun 2014 0:39 by GWiens2001 » 24 Jun 2014 0:39

YLF - that is outstanding! A real work of art.

Gordon

Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by NinjaLlama » 24 Jun 2014 5:54 by NinjaLlama » 24 Jun 2014 5:54

Well done! That looks fantastic.

-

NinjaLlama

- Supporter

-

- Posts: 51

- Joined: 9 Jul 2011 15:41

- Location: Oklahoma

Return to Lock Picks

Who is online

Users browsing this forum: No registered users and 2 guests

|