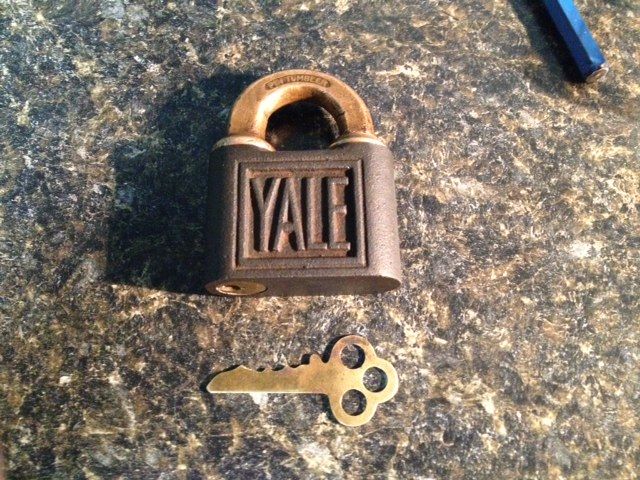

I bought this lock with two unworking keys. This is a push cylinder lock. Meaning the cylinder and the shackle are one piece and you open the lock by inserting the key, freeing the pins, then you lift and rotate the shackle.

First of all I shimmed the lock from the front. You could also pick it by putting tension on the shackle in a vise or with a rope. But this was easier for me. I used a security tag from a DVD.

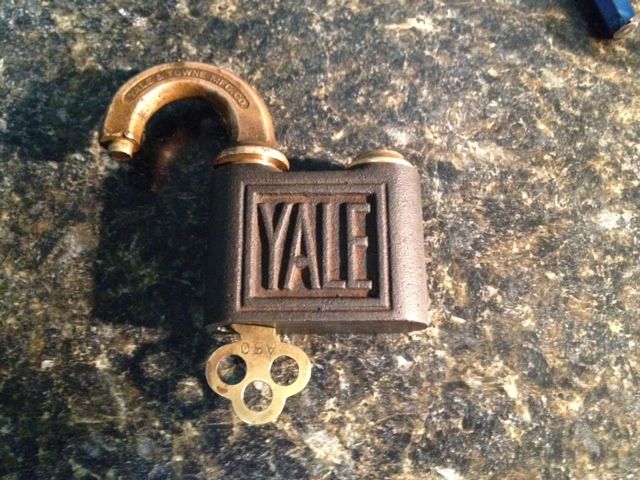

Once you can lift and rotate the shackle out of the way it's time to take off the bushing it locks into. I found that a Torx T-40 fit nicely into it. Tap it in there quite firmly so it makes grooves and grips the brass. I tried to do it gently at first, but realized that the amount of times I was taking it on and off, I was better off putting definite grooves in there that can be used over and over. You will never see these when the lock is closed and the brass will tarnish again any way. Just gently screw the bushing off.

Now it is time for the spring/shackle retainer. If you are just taking the lock apart without a thorough cleaning, you can just slide this to the side with your finger and free the shackle. I cleaned the rust out from underneath there so I removed it. I pulled it out with a punch that fit the hole snugly, being careful not to mar the threads when extracting it. Definitely wear eye protection here and I highly recommend putting a rag over it when pulling. It is liable to fling out and land somewhere in your shop and you may take the better part of an hour looking for it. Trust me that will happen.

Now you can push the cylinder out with your favorite plug follower or an 11/32nds socket.

This is how the pins looked with one of the non working keys.

I swapped pins 1 and 3 to get them all above the shear line and then filed the other key to fit. My local locksmith did have an old blank that fit, but I did not use that cause it was steel and looked too modern. There is no warding in the keyway so you could just make a key out of 0.040-0.045 brass sheet or something similar.

When you reassemble the lock. Keep the lock on its side and the shackle pointed down ,make sure that the spring finds the retaining groove between the cylinder and the shackle or the little nub on the bottom of the bushing will not seat in the hole in the spring. You will know what I'm talking about when you get there.

Congratulations, you have a working lock!!!

This was the first antique lock I have ever had/bought and it made it so much more awesome that I made a key for it myself. Thanks to this forum. I hope this helps someone in the future.