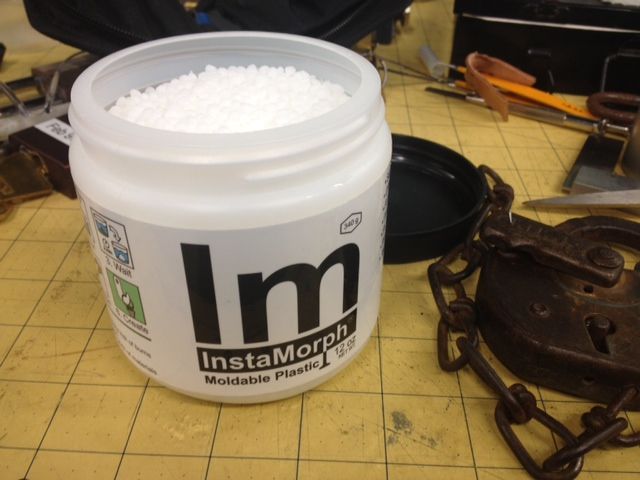

I'm working on making a key for my Adlake padlock and I will be using InstaMorph. The stuff is super cool. It is little pellets. I boil a cup of water in the microwave, pour it into a bowl and add a pinch of the pellets. They turn translucent and then you know they are malleable. Form the stuff however you want and in a few minutes the plastic slowly turns back to white and back to its original hardness.

The barrel post on the Adlake sits proud of the face of the lock so this technique works great.

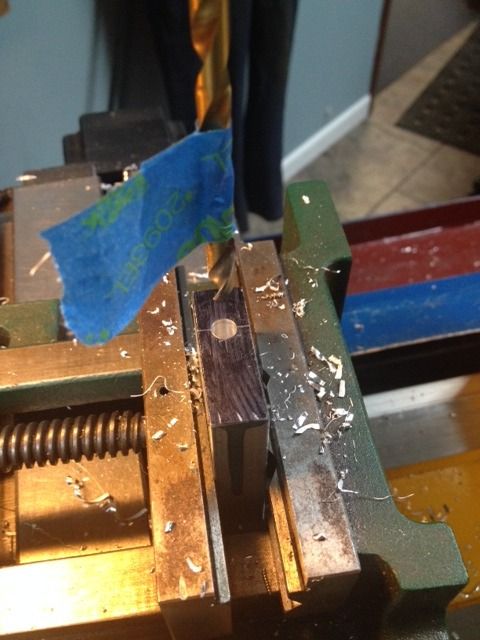

First I got my blank material and drilled the hole for the post. This locks right onto the post if you put the blank on the lock.

Next prepare a bit of the thermoplastic and pull it quite thin to go over the key hole and press your blank down on top of it making sure the post is locking into the hole in the blank and that the blank is in the orientation that you want.

You can see here that the post has pushed some plastic up into the blank's hole. Also the plastic is still warm and not quite hardened all the way.

After it is hard you can flip the piece over onto the blank and it locks nicely into the hole with a perfect imprint of the keyway.

I then cut away the excess of the template and contact cemented the remaining piece on there. I use Barge cement and let both pieces fully dry before sticking them together for the strongest bond. You don't want this sliding around in the next steps.

Hacksaw away the excess.

Milled a little.

Finally ended up at my little belt sander that has hardly any grit left.

I need to get a new belt and sand a bit more and I still need to drill and hand file the undercuts on the other side. But, I think this technique is a success over all. I have a positive line to work towards and I am absolutely sure that I am shaping it to the exact profile of the key hole.

What do you guys think?