|

Information about locks themselves. Questions, tips and lock diagram information should be posted here.

by Bowley Lock Company » 15 Nov 2015 2:55 by Bowley Lock Company » 15 Nov 2015 2:55

Mh,

Ya i found some reference to the shallow drilling from 2006 so i would imagine that patent has expired. I'll look into it further tomorrow. Not sure about the pinning one yet but i think that would be fairly hard to enforce. I threw both ideas into the patent last minute as a hail mary.

To your comment the pins are in 0.006" increments. I know regular pins are .015" apart in general on cheap locks but this lock is tight and the lock cylinder is a much bigger diameter so the sheer plain is flatter than a normal lock. I use lab pins with a .003 chamfer not .005 and from all the testing i have done .006 is enough to differentiate. I have pins in .003 increments and if you put +/- 1/2 a pin size the lock will open but the pins drag on the cylinder and its tight. 0.006" and it usually wont open. But you're right, they're pretty close together and a key with 1 bitting off on one pin might open it. It probably would if the key was 1 low rather than 1 high.

Regards,

Ryan

-

Bowley Lock Company

-

- Posts: 23

- Joined: 14 Nov 2015 22:10

- Location: calgary alberta canada

-

by femurat » 15 Nov 2015 3:35 by femurat » 15 Nov 2015 3:35

That's the one

-

femurat

- Site Admin

-

- Posts: 3762

- Joined: 22 Sep 2008 9:06

- Location: Italy

by mh » 15 Nov 2015 10:03 by mh » 15 Nov 2015 10:03

@Ryan, You could fill the space at the "front" of the keyway with metal ("XX" in the ASCII art below) and make the part of the key with the cuts shorter, so that the 1st pin sits only on a side ramp, not in a "full valley". That way, bumping the 1st pin by pushing the key towards the back of the lock won't work. - Code: Select all

|| || || || || <- Pins

\/ \/ \/ \/ \/

XX _/\_/\_/\_/\___

XX|___________ | <- Key

| |

Cheers mh "The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by Bowley Lock Company » 15 Nov 2015 11:12 by Bowley Lock Company » 15 Nov 2015 11:12

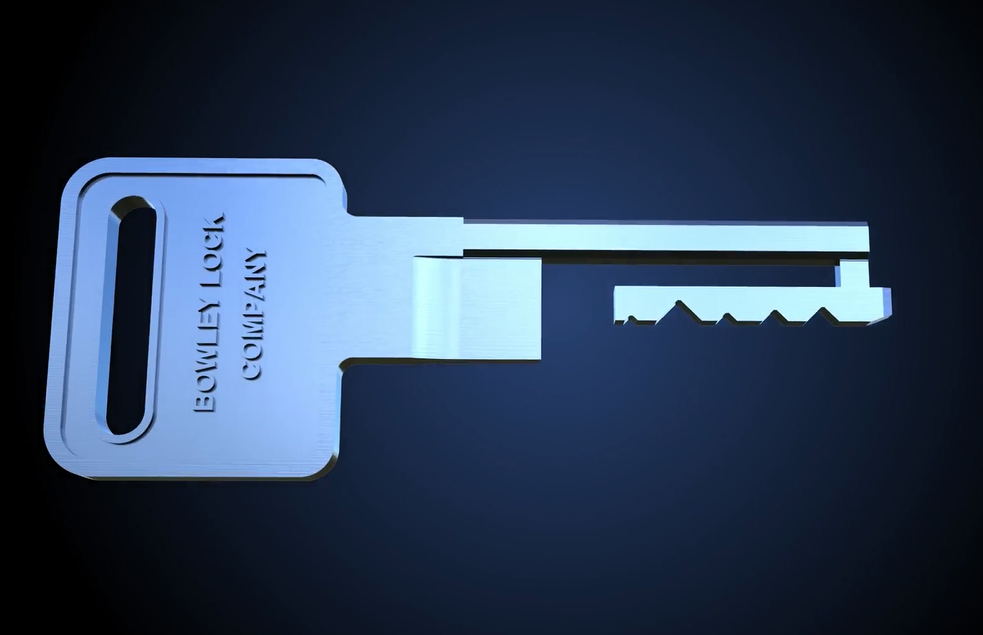

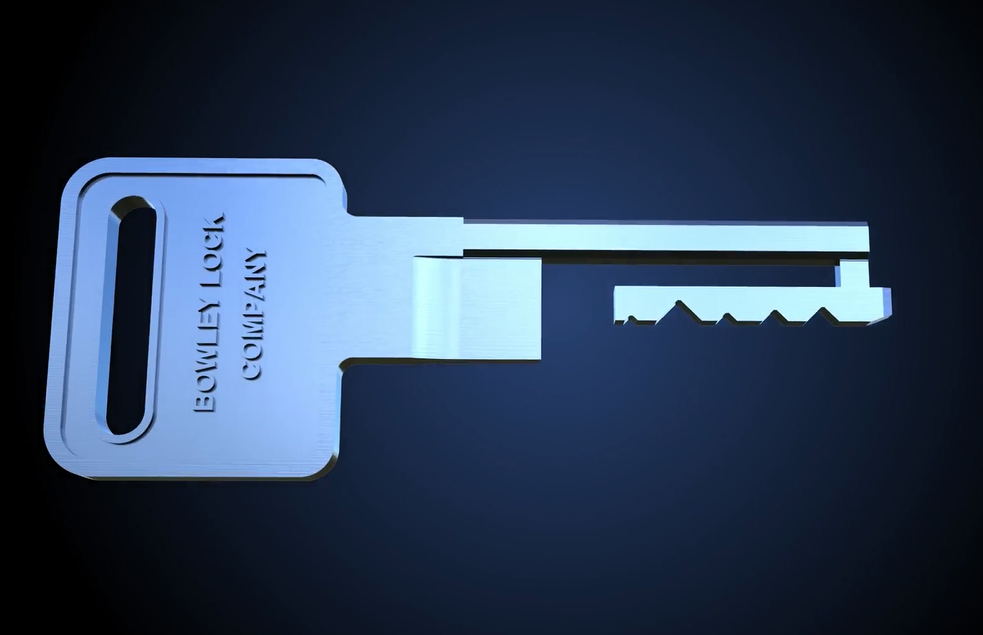

Mh, Fantastic drawing by the way. If i understand you correctly that is what the current key looks like. Below is lockmans28 video at the close up where you can see that the last cut just has a small landing and It has no back side to the bitting. I didn't even notice that the animations do not show this properly. https://youtu.be/1MnZM8Pkvmw?t=163however a bump key would need the bitting shifted forward on the key so then you have the extra room at the end anyway.

-

Bowley Lock Company

-

- Posts: 23

- Joined: 14 Nov 2015 22:10

- Location: calgary alberta canada

-

by mh » 15 Nov 2015 11:46 by mh » 15 Nov 2015 11:46

Cool, so the 1st pin can't be bumped and bump keys with different depths on the 1st cut position are required.

"The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by jbrint » 16 Nov 2015 8:31 by jbrint » 16 Nov 2015 8:31

I wonder what the tolerances of that key are. I would be concerned about having that hang from my belt loop, get bent and me be screwed. The lock looks really cool though.

-

jbrint

-

- Posts: 208

- Joined: 7 Aug 2015 22:27

- Location: Houston, Texas

by GWiens2001 » 16 Nov 2015 9:07 by GWiens2001 » 16 Nov 2015 9:07

I can - easily - see that hooked section catching in my pocket, grabbing other key rings, snagging on the edge of the pocket. Like the unique design.

Gordon

Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7609

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by mh » 16 Nov 2015 9:32 by mh » 16 Nov 2015 9:32

Bramah's keys caught too much pocket lint. So they introduced caps. No big deal.

In today's Kickstarter world, I could imagine them made from high grade titanium or something like that.

"The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by kwoswalt99- » 16 Nov 2015 14:36 by kwoswalt99- » 16 Nov 2015 14:36

mh wrote:Bramah's keys caught too much pocket lint. So they introduced caps. No big deal.

In today's Kickstarter world, I could imagine them made from high grade titanium or something like that.

I think stainless would be better.

-

kwoswalt99-

-

- Posts: 1218

- Joined: 17 Mar 2015 15:35

- Location: Somewhere.

by Bowley Lock Company » 17 Nov 2015 0:00 by Bowley Lock Company » 17 Nov 2015 0:00

Hey guys, The key really doesn't seem to catch in my pocket at all, and i have had this key on my key chain for 6 month. We designed it with a shoulder that comes off the handle that is higher and proud of the hook. I specifically called my friend who has been testing the key for me to ask him if he has had any trouble. He is a postman and walks 20km a day and he told me it has not caused him any problems so far either. It certainly can hook a loose thread or if your pocket is mesh that could be tricky, but certainly this key hooking on some part of your clothes is not going to bend the bitting portion. If I push down on it with my thumb as hard as i can it will not move and it is painful. It is hard to appreciate until you have it in your hands so i understand peoples concern. Keep in mind this material is as strong as a 12.9 bolt or socket head cap screw the strongest fastener you can buy. I would liken it to having a 1/8" allen key in your hand and trying to bend it with your thumb or in your pocket.  http://www.bowleylockcompany.com/upload ... 1_orig.png http://www.bowleylockcompany.com/upload ... 1_orig.pngHope that lessens some of your concerns, Ryan

-

Bowley Lock Company

-

- Posts: 23

- Joined: 14 Nov 2015 22:10

- Location: calgary alberta canada

-

by cj101 » 17 Nov 2015 0:32 by cj101 » 17 Nov 2015 0:32

According to your earlier post, there will be 9 pin heights in steps of 0.006"=0.15mm. Hence there will be just a total maximum variation of just 1.2mm height variation. This sounds too me very ambitioned.

You need a plug tolerance of at least 1/50mm-1/20mm to ensure smooth turning. Furthermore the drilling holes and pins must be chamfered to ensure smooth operation. Last the lock will be worn out after some time. Adding up all tolerances, I believe a small series of tryout keys can be produced.

Can you achieve the necesarry tolerances in mass production? Doesn't this make your lock much more expensive than necessary?

Why don't you increase the number of pins instead?

-

cj101

-

- Posts: 74

- Joined: 9 Dec 2014 15:38

by Bowley Lock Company » 17 Nov 2015 1:51 by Bowley Lock Company » 17 Nov 2015 1:51

Cj,

The lock will be made on a Swiss lathe/screw machine because i need it to be tight for the reasons you mention. And your tolerances are very close to the actual call out. Like any design there are trade off's that you balance. Choosing deeper key bitting means one of the following trade offs: less shield thickness, less shank thickness or larger cylinder diameter which then shifts the axis of the cylinder up. I have considered smaller pins and going to 6 but they are harder to find. We certainly intend on doing a dual fork version like a reverse pitch fork (10pin) but it may require a bigger housing because the pins will be horizontal and the axis centered.

Even if the a key opens it or any combination of actual or actual -1 bitting height -0.006" there would still be at at least 1025 keys to try and i don't think you would get that much play in a given location for a very long time.

It would be nice to have larger steps.

Thanks for you comment.

-

Bowley Lock Company

-

- Posts: 23

- Joined: 14 Nov 2015 22:10

- Location: calgary alberta canada

-

by mh » 17 Nov 2015 2:21 by mh » 17 Nov 2015 2:21

Ir might be reasonable to assume tryout keys that are designed so that they can be jiggled / tilted up and down, back and forth, and therefore cover a larger number of key codes each.

Maybe also consider two halves that are inserted into the lock together, each one interacting with other parts.

The other thing to look at are foil impressioning systems for dimple locks.

These attacks are made easier if the pins don't have to move much and the pin steps are so small.

Cheers

mh

"The techs discovered that German locks were particularly difficult" - Robert Wallace, H. Keith Melton w. Henry R. Schlesinger, Spycraft: The secret history of the CIA's spytechs from communism to Al-Qaeda (New York: Dutton, 2008), p. 210

-

mh

- Moderator

-

- Posts: 2441

- Joined: 3 Mar 2006 4:32

- Location: Germany

-

by Bowley Lock Company » 17 Nov 2015 18:39 by Bowley Lock Company » 17 Nov 2015 18:39

Thanks alot,

Im going to play around with the components to see if i can't buy my self some more bitting height on the key. It certainly sounds like.009" steps would be better than .006" and i may be able to find .030" to pay for it.

Thanks a lot for the feed back.

-

Bowley Lock Company

-

- Posts: 23

- Joined: 14 Nov 2015 22:10

- Location: calgary alberta canada

-

by kwoswalt99- » 17 Nov 2015 20:55 by kwoswalt99- » 17 Nov 2015 20:55

What's your vision for the company?

-

kwoswalt99-

-

- Posts: 1218

- Joined: 17 Mar 2015 15:35

- Location: Somewhere.

Return to Locks

Who is online

Users browsing this forum: No registered users and 5 guests

|