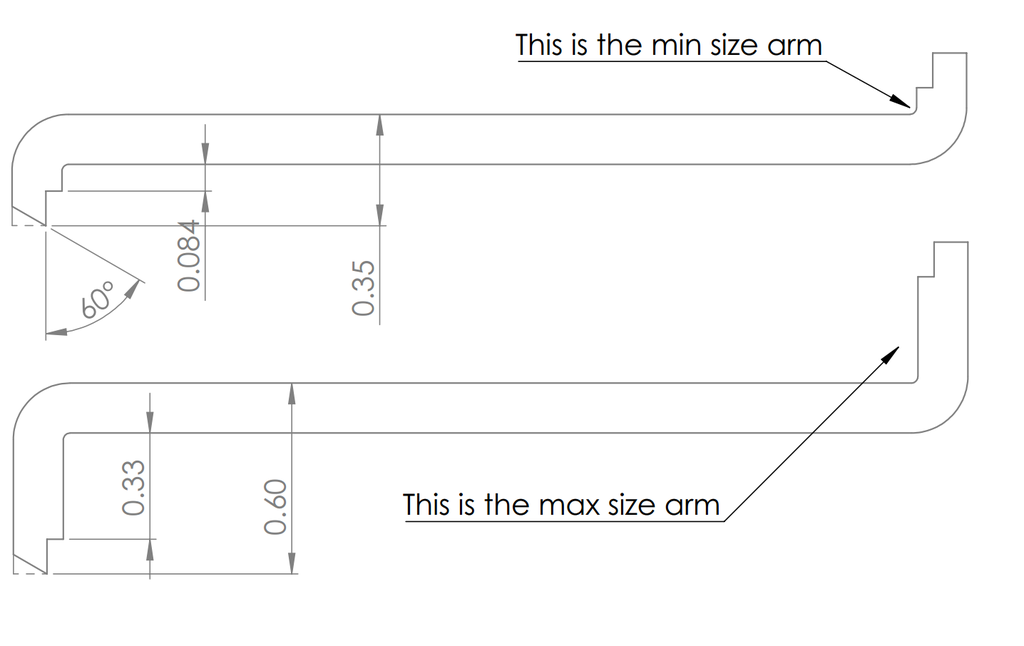

We currently have drafted seven tensioners, each having a chamfered end and a square end. The idea of having a chamfered end is so that there will be less surface area for the tensioner to bind up the front pin (this has not been prototyped, does anyone have experience with chamfering TOK tensioner to reduce front pin binding?) The arms of the seven tensioners range from 0.34" to 0.60" in length (the attached PDF shows the shortest and longest tensioners)

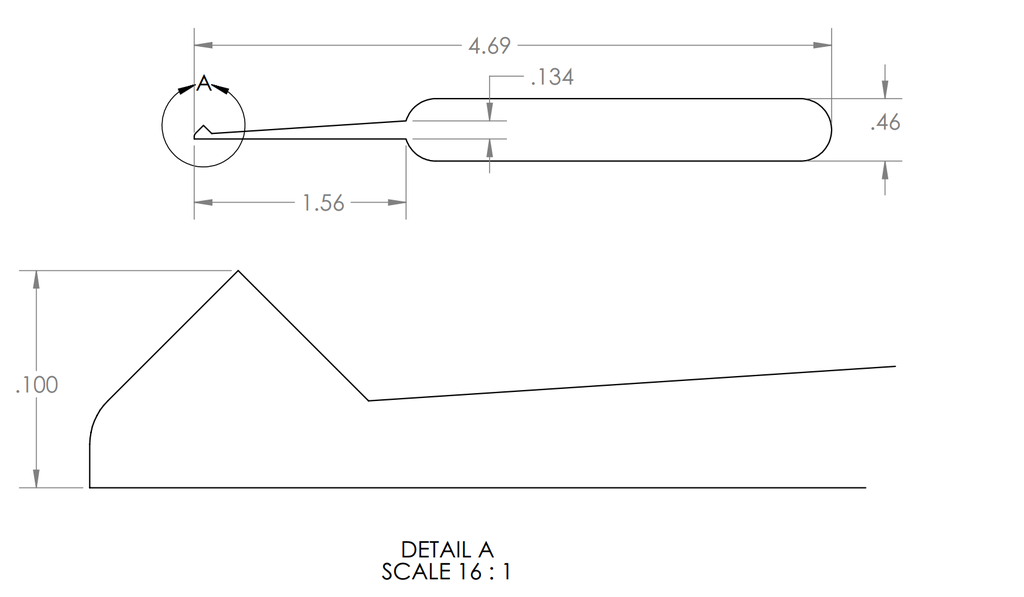

All diamond picks have been modeled and range from a bottom of pick-to-top of diamond height of .05" to .31." The increments between heights are different for picks in ranges 0.11”- 0.31” (0.03” increments) vs ranges 0.05"- 0.10" (0.01” increments.) Note that the toe of the diamond pick has truncated and rounded. The theory behind this design is if the pin behind the one you are picking is already set, you will be able to raise the target pin higher without interfering with the set pin. This has been prototyped but I don't want to influence comments by relating the results. With regard to the height increments, we want a way of decoding the approximate pin depth so that a key can be easily made once the pin(s) has/have been set. Doing this with hook picks would also allow a pin-depth decoding with hi-lo combinations.

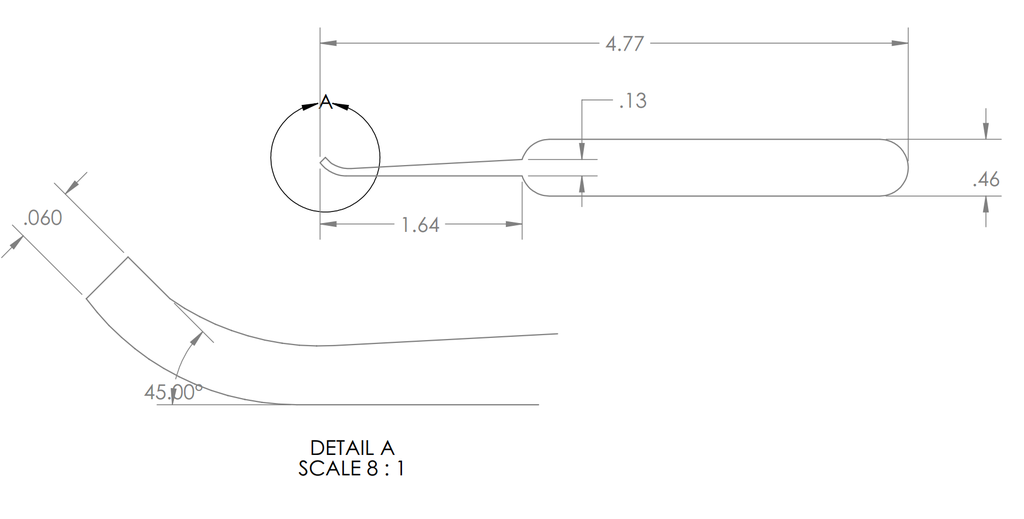

We plan to increment the hook picks with a maximum height of 0.028. We haven’t decided on a diamond profile on the picking surface (as with a Peterson Gem) or a rounded surface with maybe a tiny dimple (like a hybrid between the Peterson lifter pick and Peterson reach.) Again, this has been prototyped but results are not given at this time so as to not influence feedback. We haven't agreed on an ideal angle for the hooks, but are currently discussing a different angle for each hook height (suggestions?)

Also, a different approach to an old idea: We also intend to use a laser engraving printer to put a mm scale on one side of picks and a 0.01” scale on the other side. This will help you measure what pin you are on by reading off the scale on the pick (e.g. you would push the pick against the 1st pin and read how far it was beyond the keyway opening and know what pin you were on.) We will also engrave the bottom-to-top height of the pick for use with decoding.

For material, I am thinking stainless spring steel with maybe a .025" thickness? That is 0.005” thicker than I used for my first EDM pick.

Again, there are some interesting ideas here, I'd like to know what the community thinks of them, as the final products will take a lot of work. This is a peer review and I have no emotional investiture (until they are made!) so please don't hold back and let me know what you think. Thank you for the support over the years, I have really grown as a result of this community.

~Fox