a guide for warded door locks

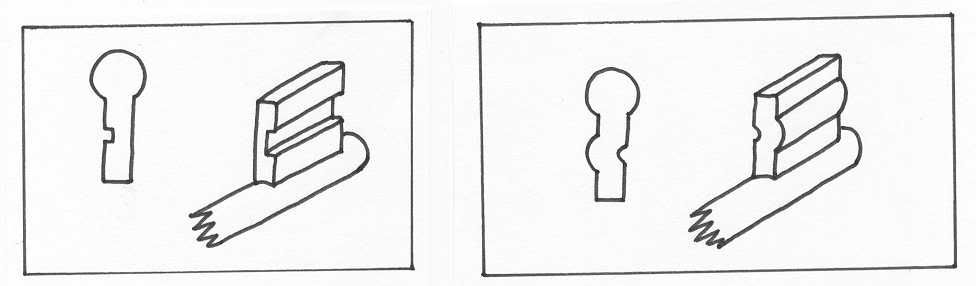

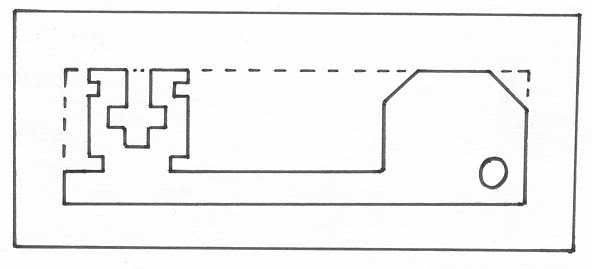

Warded Locks, below are two examples of keys for warded door locks

on the left we have an iron key for an antique lock, and on the right a modern steel key for a union lock. both of these are real life keys in current use in the uk, and both of them are using the same technology to provide their security, wards. (note there will also be one or two levers in the lock to prevent the bolt from freely sliding, many lever locks (from 3 to 9 levers) may also employ warding of some form. in general if the majority of the security is being provided by warding i would consider it a warded lock.)

What is a ward?

a ward is a piece of metal built into the locks design which prevents similar keys from fitting into, or turning fully, to open a lock.

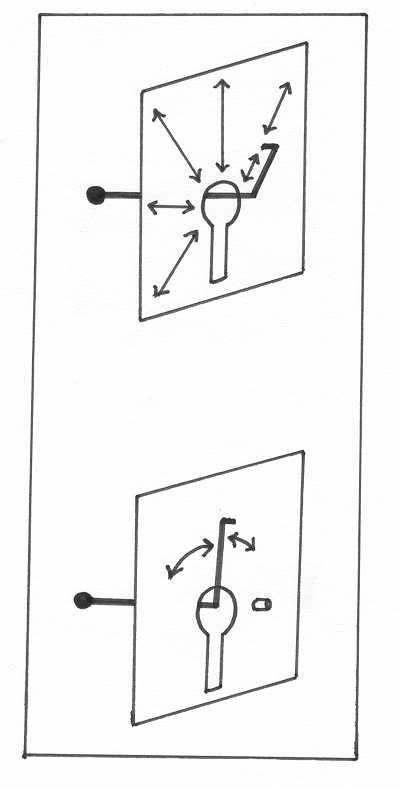

Keyway wards (case wards, u.s.)

an unusually shaped key hole which prevents an incorrect bit from entering the lock.

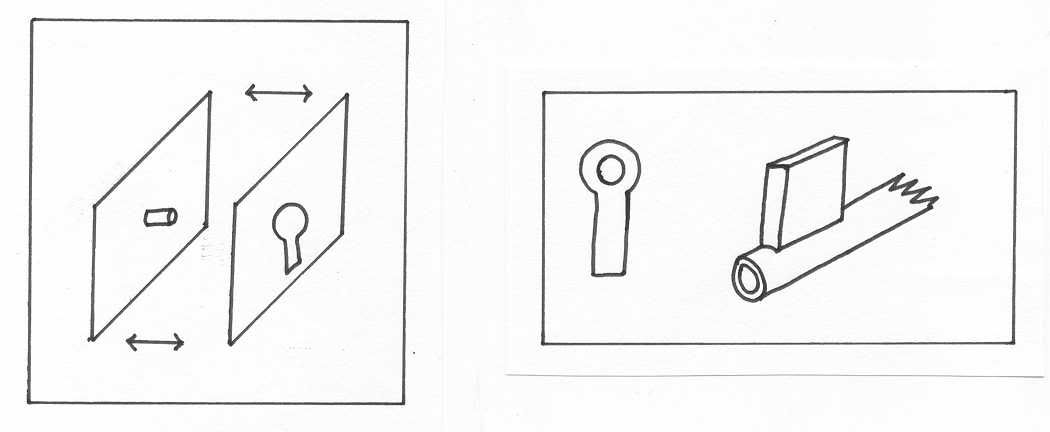

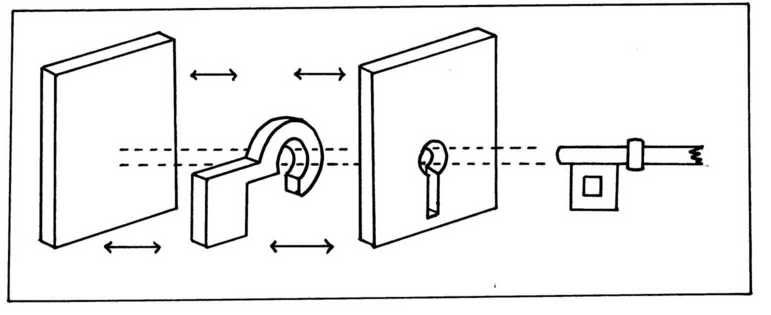

Key post

this form of ward is only found on one sided locks, ie. padlocks and chests. the post is attatched to the back of the lock case and reaches into the keyway at the front. the key for this type of lock has a hollow stem which accomodates the post when in use.

occasionally you may have a key and lock which have stopped working, try cleaning out the key's stem hole to ensure that the key can enter the lock fully.

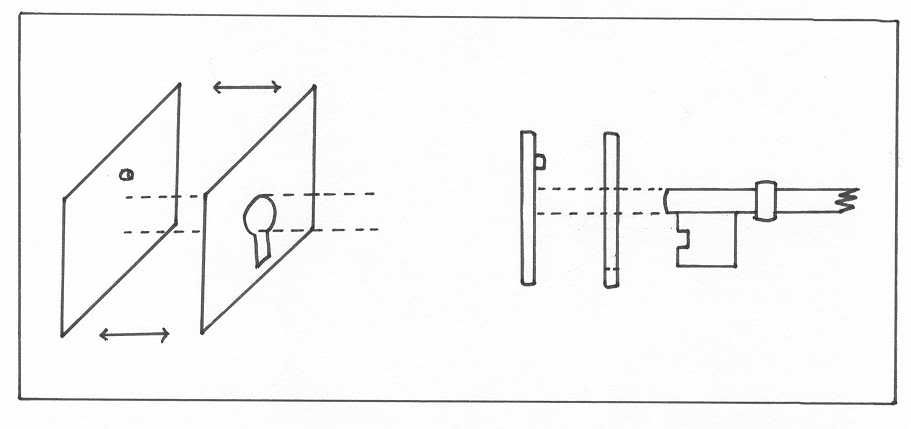

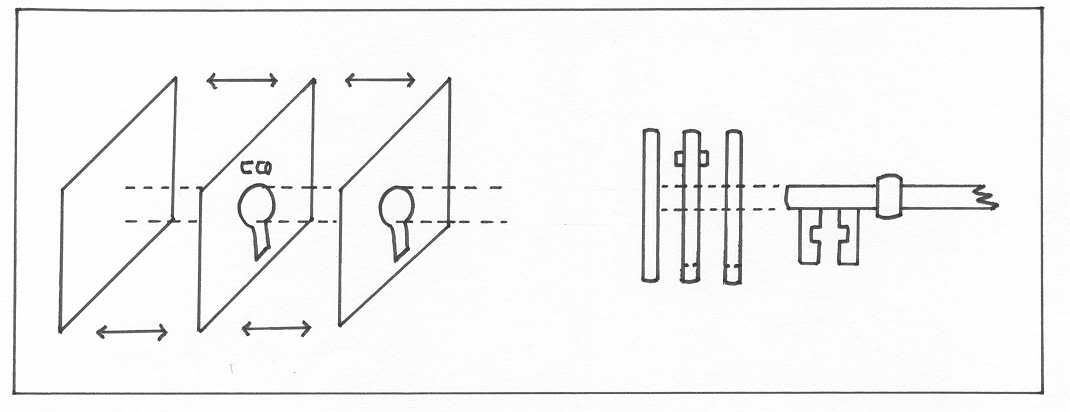

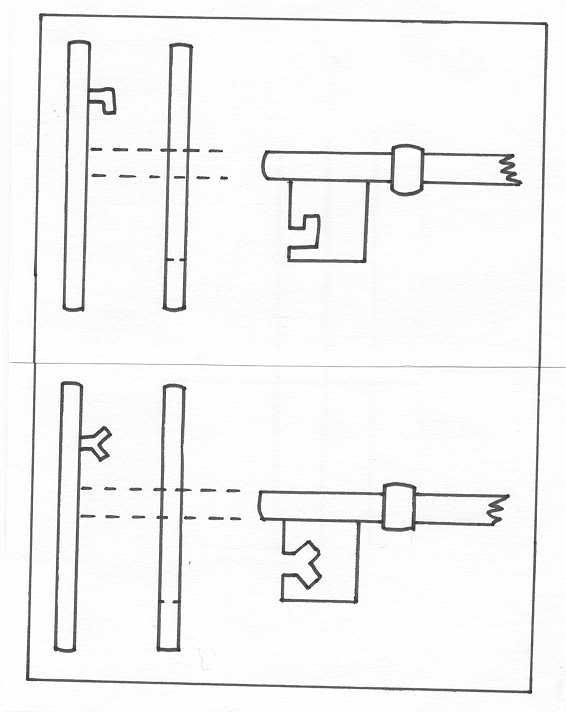

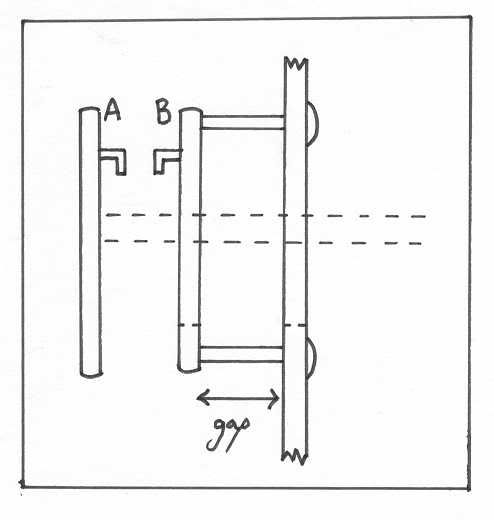

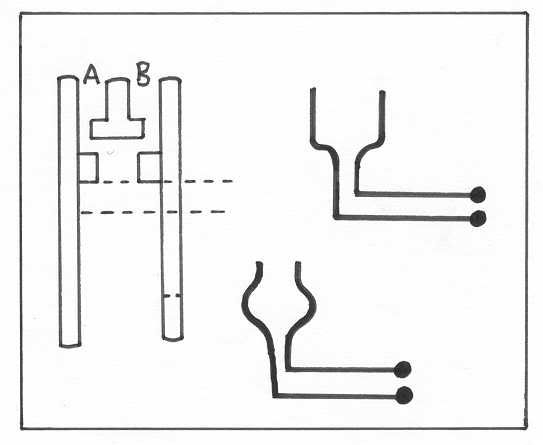

Partition wards

a full partition, or dividing ward, is like a second face plate set inside the lock.

note: the ward touches the key stem.

Partition wards can also be partial.

note: this ward will only block the centre top of the key bit.

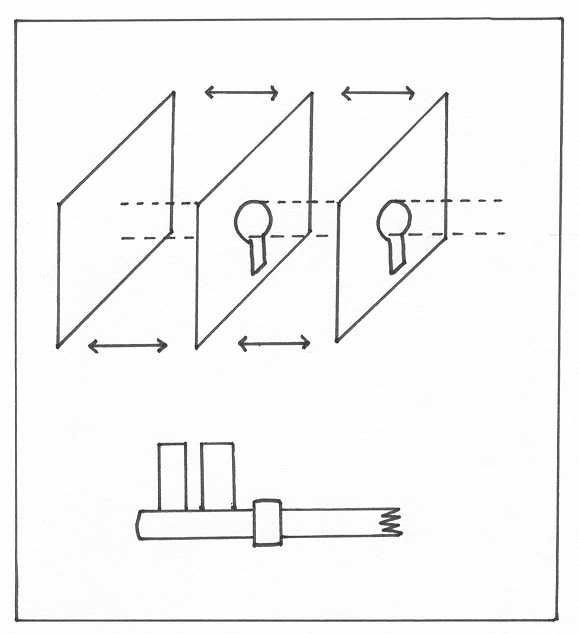

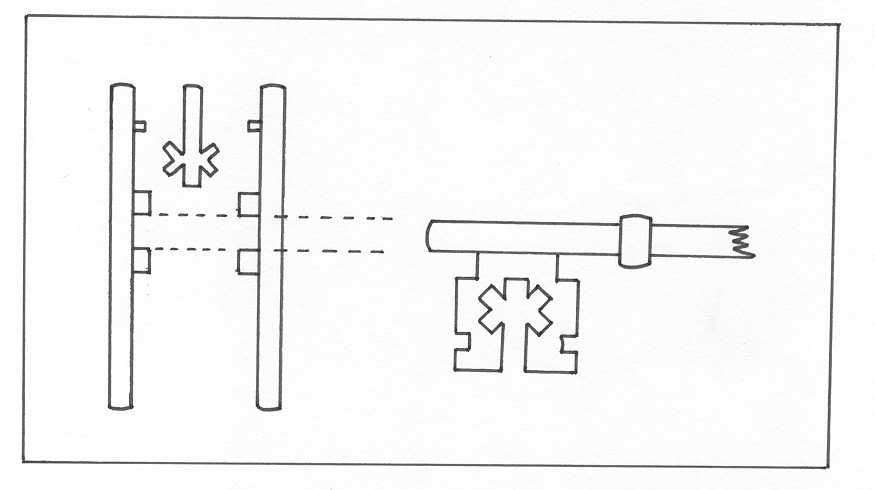

Pin or point wards

small pins or raised points on the inner surfaces of the lock in the path of the key bit.

These may also be attatched to one or both sides of a partition ward.

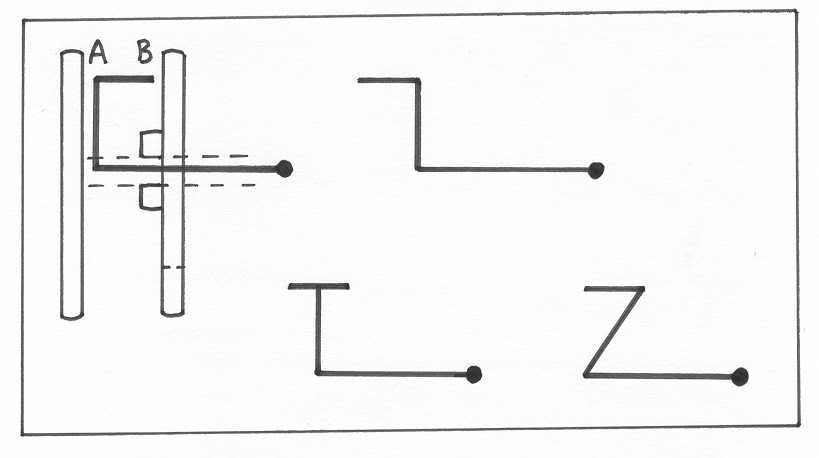

Track wards

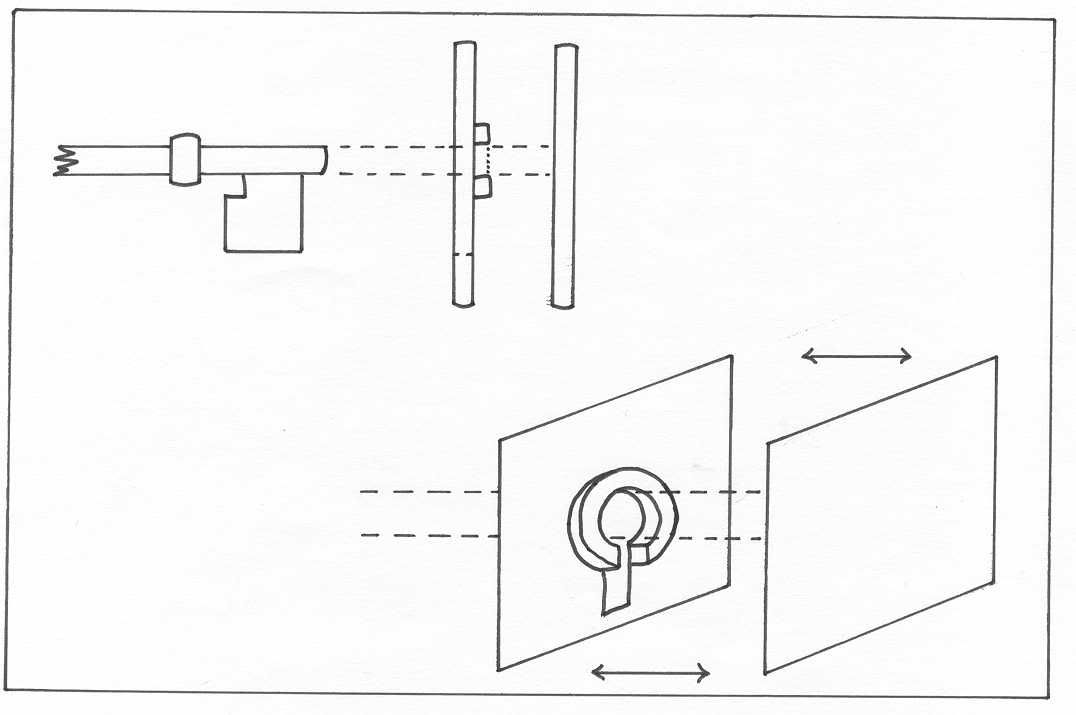

an obstruction which is continuous along the path of the key bit.

the example above, a continuous ward around the top of the keyway, is also known as a collar ward and is found in many lever locks.

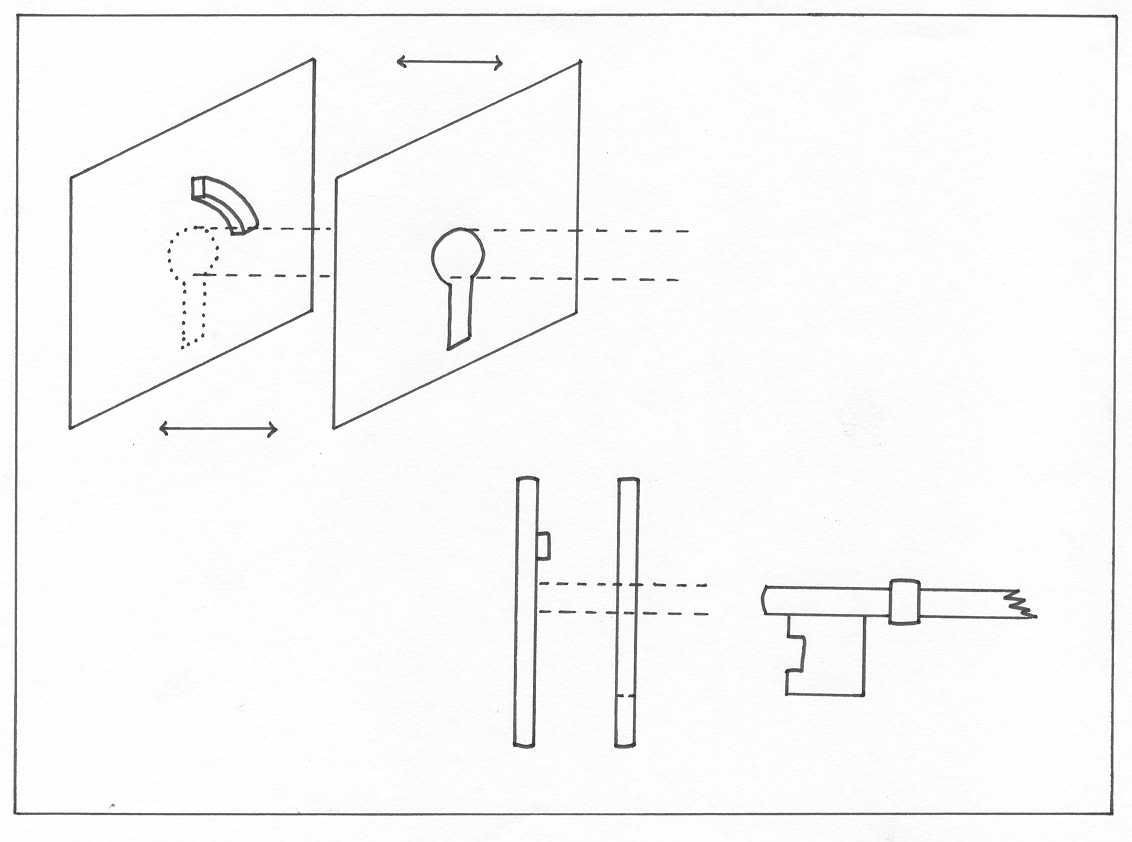

Partial track ward

a semi circular ward section

this is less prone to damage than a pin ward, and easier to make by hand than a full track ward.

not all track wards are rectangular in cross section;

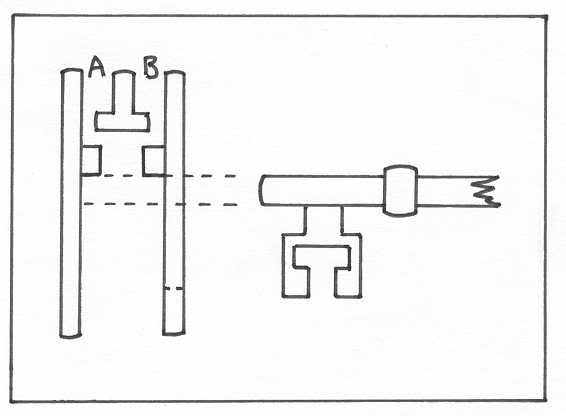

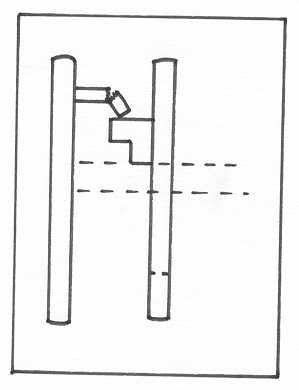

Free floating track wards

These are semi circular wards secured to the lock at one end. the key "threads" onto this ward then cannot be removed untill the lock is reclosed. like modern key retaining locks, this is usually found in higher security applications, ie. old cell doors and safes.

All of the above wards can be used in various combinations for greater security, and all of the above have been shown as single sided locks. have a look at some old keys and think about how the corresponding locks may be constucted internally.

the lock above may have pin wards but they could also be tracks. it may have a partition with tracks or it could be floating track, and hence key retaining, keep an open mind.

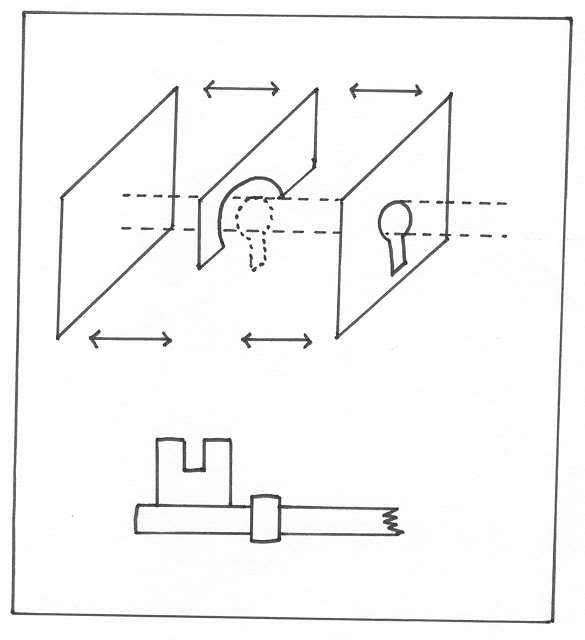

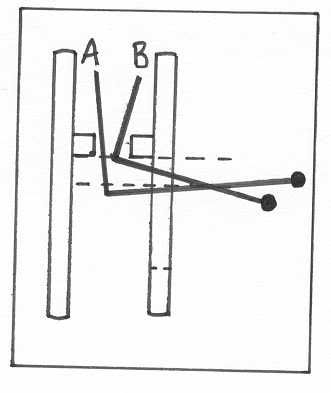

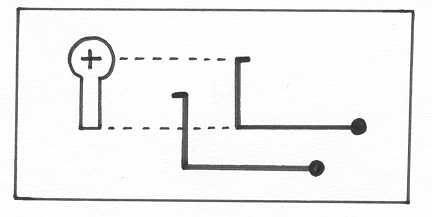

Picking

What do we need? for the basic lock model we need nothing more than two "L" shaped wires, one to slide the bolt accross (at A), and one to raise the lever or levers to the correct height (at B)

and these two basic picks will still do the job in a lock with simple warding

you may even be able to open the lock with only one wire, raising the lever and throwing the bolt in one move (as you would with the key).

however neither of these will work in the folling lock, with "L" wires being blocked by the side mounted wards and "one turn openers" being blocked by the partition

we'll need specially shaped wires for this lock.

Which wires to use?

in order to open the lock, it will help to have an idea what the insides are like.

look;

is there a key post? is the lock single or double sided? are there keyway wards? can you see a collar ward or a partition?

note: beware a lock built seperately and then bolted inside a metal trunk, it may appear to have a full partition, while in fact you may be mistaking the front case of the lock for a ward.

look at the bolt heads around the keyway and ask yourself if there are four suitably well placed for the task of holding the lock in situ.

feel;

use straight, "L" shaped, shallow buttonhook and reverse buttonhooks to probe

it may help, with complex warding, to stick a couple of post-it notes to the door and record where you feel the wards.

use the straight probe to gauge the lock's depth and the depth to any partitions it can reach.

use the "L" shaped wire; to feel for bolts in the metal box example above, to check for partial partition wards, and to feel if it's possible to move the bolt and levers with two "L" wires.

use the tips of the buttonhooks to feel out radially accross the insides of the fornt and back plates of the case, as well as both sides of any partitions.

then use the flat sides of the buttonhook probes to sweep for pin wards which are easy to miss.

now armed with a mental picture of the wards you should be able to select, or make up, a wire or pair of wires to bypass the wards and open the lock.

Problems that may be encountered:

you've got what you think are the right shaped wires, but you're hitting something unexpected. stop. mark it on your post-it note maps. use your picks or probes to try and feel what it may be; a pin that you've missed? if your sure that there are pins is one bent or broken? or is there a partial ward that you can't reach with a probe? for the above lock i showed two sets of wires which could do the job, but if there were additional track or pin wards on the case at the top, then the top set of picks would be blocked, while the lower picks would do the job.

try blacking your picks over a candle flame, then carefully insert and turn to your sticking point, give them a little rub against the blockage and remove with care. where your picks have rubbed against wards the soot will have worn off, look for unexpected marks, think about possible extra internal wards and try re-shaping your picks. if both sides of the lock seem symetrical, and only one of your picks is jamming, then check it's shape against the good one.

the owner has the key but it won't work

if the lock hasn't been used in a long time it may just be stiff, however if it was opened recently then chances are that a ward is damaged. use you judgement, have a go and see where it's stopping.

the most likely ward to be damaged is a pin ward, try probing for it, although it may be quicker to soot the key and turn it to locate the problem.

What to do about a damaged pin?

if it is bent you may be able to enlarge the gap in the key to pass the bent pin. if it's broken.

then the piece must be removed. in some cases you may be able to remove the lock and disassemble it to extract the broken piece, in others you must break out the piece using a stout pick and brute force.

another problem ward may be the free floating track ward. either the key may be failing initially to line up with the end of a bent ward, or it may start fine before becoming stiffer as you turn the key. in both these cases it may be possible to enlarge the hole in the key to solve the problem.

damage to partition wards and surface mounted track wards is fairly unlikely, and even if a piece rusts through it shouldn't interfere with the working of the key.

Impressioning

find a sutible blank, the stem gauge and bit size can all be measured from the lock. with key way wards if you can't find an exact match then depending on the value of the lock in question you can either file a section from accross the key bit, or remove the warding from the keyway of the lock itself.

smoke your blank over a candle flame untill there's a good coating of soot. carefully insert the blank and turn it to try nad open the lock, remove your blank and see where the soot has been rubbed away by the wards. (i would strongly recomend performing the probing and mapping exercise, and looking for partitions and visible wards, as well as reading the marks from the impress. don't forget that if the lock is double sided then the bit will be a symetrical pattern)

using a good metal file remove the marked areas to create gaps for the wards to pass through. (use a router, cutting wheel, drill etc. where nescessery.) be careful not to over do it, you can always file a bit more off, it's not so easy to glue the filings back on

clean up all the rough edges and resmoke your key, then try, file, clean, soot, try again. don't rush, don't get careless and don't believe you've got plenty spare metal on your key bit, alwats imagine that there might be one more ward a bit further round, think about your key where could it fit?

hold off cutting the top of the bitting as long as possible, it's here that mistakes are the least forgiving. on modern locks there may be two levers try picking first, so that you'll have an idea of the keys bitting.

if you can't get a suitable blank straight away, but a temporary key is needed for an larger lock, ie. church door, then you may be able to cut a flat key to do the job out of a strip of cold rolled iron bar.

comercially available picks, set "O",https://shop.multipick.com/en/opening--locksmith-tools/lock-picking--lock-manipulation/lever-picks-opening-hooks/lever-pick-set-o, or make your own.

check out the following,

http://www.buildingconservation.com/art ... /locks.htm End note

wards are often considered poor security, but imagine removing a couple of levers from a bs lever lock and inserting a full partition ward, we'd all have to buy 3 in 1 cutain picks as well, or the addition of a track ward on the inside of the face plate in a 3g114 etc would block a pin & cam.