|

Bump keys and lock bumping finally have their own area. Discuss making bump keys, proper bumping techniques, and countermeasures here.

by demux » 10 May 2017 12:32 by demux » 10 May 2017 12:32

So, this may be a silly question, but I'll go ahead anyway. Does anyone know how bumping actually, really works? From a physics perspective? I've always heard the Newton's cradle description, which as a non-physicist but someone who has taken some physics courses, seems the most plausible to me. I see on another thread in this forum ( viewtopic.php?f=32&t=57437) that this has been called into question, but it seems like that never got authoritatively resolved. I've also seen the Master BumpStop promotion video, but that seems a bit of a stretch to be believable to me (and with Master being, well, Master, and generally more concerned with marketing and hype than pesky little things like facts, I don't put a lot of stock in what they say anyway). I ask because I've been thinking of possible ways to mitigate bumping, and had an idea that still seems sane to me even after a few days of mulling it over, but it's based on the Newton's cradle theory. What if you were to split the driver pin into a "top" and "bottom" driver, such that the following was true: 1. The "top" part of the driver was sufficiently small that it always sat above the shear line. I.e. it was basically just an intermediary between the spring and the "bottom" driver, which actually spanned the shear line to keep the lock locked.

2. The "top" part of the driver was mass-matched, as closely as possible, to the mass of the key pin in any particular chamber.

If the Newton's cradle theory is correct, then in theory when such a lock would be bumped, the energy of the impact of the bump key against the key pin would be transferred through the "bottom" driver (and any master pins installed in the cylinder) and cause the "top" driver to jump. Since this pin was already sitting above the shear line anyway, this should result in no gap that would allow the lock to open. If the masses were matched closely enough, then there should be minimal movement of anything in the pin stack except that "top" driver. Anyone ever tried anything like this before? Wanna poke holes in any parts of my theory? I've got half a mind to go pin up a couple of cylinders of the same make/model with identical bittings, but one with this mod and one without, and just try bumping each and see what my success rate is over 50 or 100 tries. But figured I'd ask here first in case anyone can think of any reason why I'm obviously heading down the wrong track. Like I said, I've taken some physics courses, but am not at all a physicist, so it's entirely possible I'm completely overlooking something very basic.

-

demux

-

- Posts: 523

- Joined: 27 Apr 2017 11:14

- Location: Indiana, USA

by Jacob Morgan » 10 May 2017 14:59 by Jacob Morgan » 10 May 2017 14:59

I probably do not completely understand the part about the driver pin being above the shear line--it would stop bumping, but it would also prevent unlocking with the key as well?

Try looking up the Ilco Bump-Halt kits. Uses a low-mass top pin and a heavy spring. The mass and spring in one or two chambers is thusly made very different from other chambers and that makes bumping almost impossible.

-

Jacob Morgan

- Supporter

-

- Posts: 571

- Joined: 30 Dec 2015 21:31

- Location: KY (north west)

by demux » 10 May 2017 15:10 by demux » 10 May 2017 15:10

Jacob Morgan wrote:I probably do not completely understand the part about the driver pin being above the shear line--it would stop bumping, but it would also prevent unlocking with the key as well?

I'm thinking a driver in two parts. So for the simplest case (a lock with a single operating key), there would actually be three pins in each chamber, a key pin, a lower driver and an upper driver. The split between the upper and lower driver parts would always be above the shear line. This is where I would expect the gap to open when the lock is bumped. The split between the key pin and the lower driver would be aligned with the shear line when the correct operating key is inserted. Hope I explained it well enough there.

-

demux

-

- Posts: 523

- Joined: 27 Apr 2017 11:14

- Location: Indiana, USA

by Squelchtone » 10 May 2017 15:40 by Squelchtone » 10 May 2017 15:40

This is discussed in another thread where a lock has master pins/wafers in the stacks. viewtopic.php?f=32&t=59909A thread discussing if the Newton's Cradle is a good example of bumping or not: viewtopic.php?f=32&t=57437You will probably find much more with the Search tool or in google search by typing something like: bumping physics site:lockpicking101.com the "site:" command tells google to only search lockpicking101.com for the key words bumping physics hope this helps Squelchtone

-

Squelchtone

- Site Admin

-

- Posts: 11336

- Joined: 11 May 2006 0:41

- Location: right behind you.

by demux » 10 May 2017 18:56 by demux » 10 May 2017 18:56

Thanks Squelchtone. I actually did see both of those threads (and referenced that last one), but I'm thinking specifically of putting an additional pin above the driver, not between the driver and key pins where you would normally put a master pin. In the searching I did, I didn't see anywhere where that had been discussed previously. (It's possible I missed it or didn't search the right terms, of course).

-

demux

-

- Posts: 523

- Joined: 27 Apr 2017 11:14

- Location: Indiana, USA

by GWiens2001 » 10 May 2017 19:17 by GWiens2001 » 10 May 2017 19:17

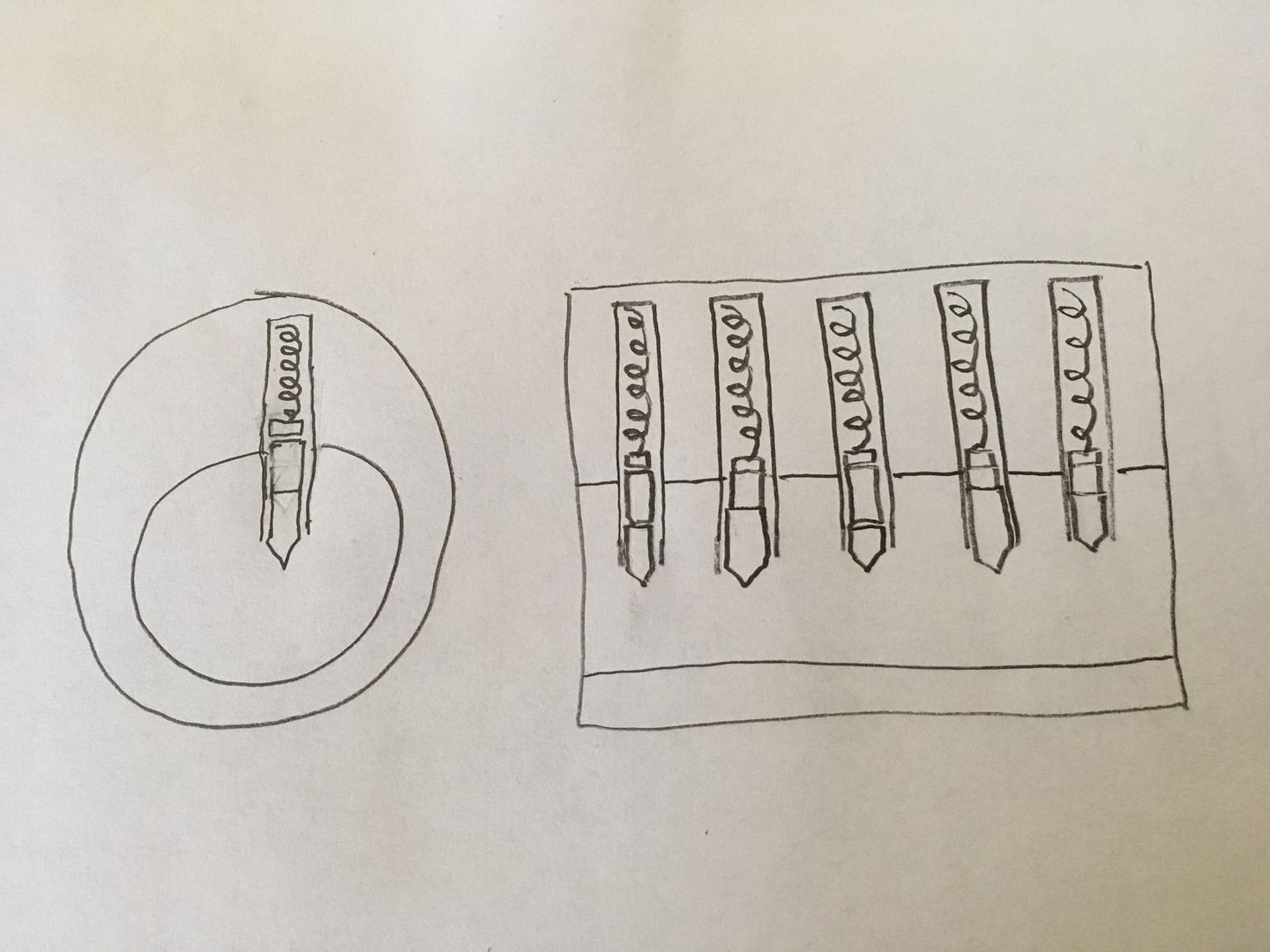

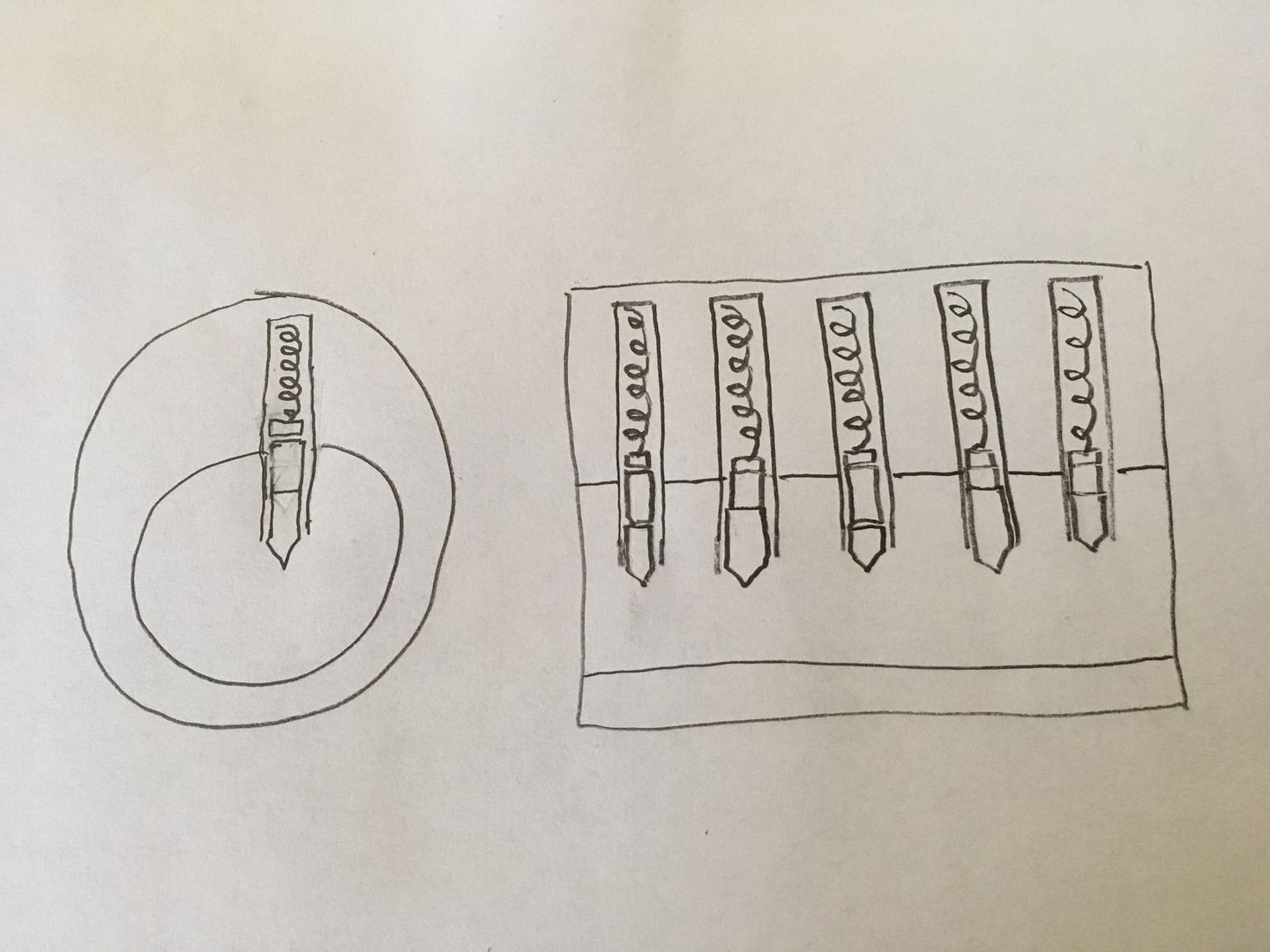

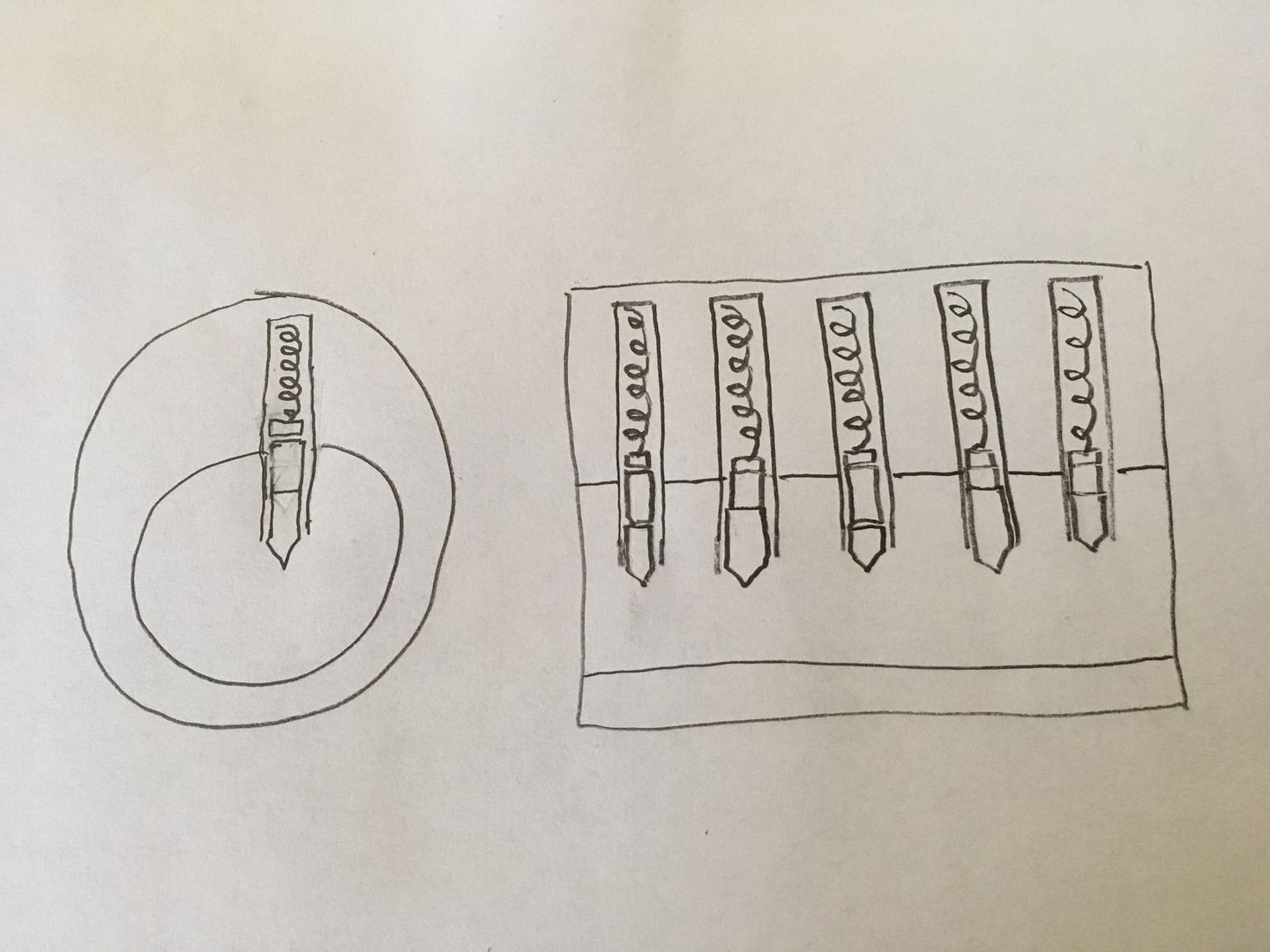

I can visualize what the OP is stating. Normal key pin. Normal driver pin, but the driver pin is short enough that it only barely goes above the shear line (meaning that it does the normal job of blocking the shear line without ever dropping down enough to reach the shear line), then above that another pin (pretty much a small master pin) above the shear line. Newton's cradle effect would then cause only the topmost pin to move up when bumped. There is never a gap created by bumping at the shear line. Something like this:  Gordon Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7619

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

by kwoswalt99- » 10 May 2017 20:12 by kwoswalt99- » 10 May 2017 20:12

Pin up a cylinder and test it.

-

kwoswalt99-

-

- Posts: 1218

- Joined: 17 Mar 2015 15:35

- Location: Somewhere.

by Squelchtone » 10 May 2017 21:05 by Squelchtone » 10 May 2017 21:05

demux wrote:(and referenced that last one),.

heh.. coffee.. it's whats for dinner. I obviously need another one!

-

Squelchtone

- Site Admin

-

- Posts: 11336

- Joined: 11 May 2006 0:41

- Location: right behind you.

by Robotnik » 10 May 2017 21:24 by Robotnik » 10 May 2017 21:24

kwoswalt99- wrote:Pin up a cylinder and test it.

There's a thread on here where I did exactly that...still bumped easily. I've always found the Newton's cradle analogy problematic - I've yet to see a cradle that has a spring resisting movement of the balls.

-

Robotnik

- Supporter

-

- Posts: 668

- Joined: 3 Aug 2014 16:21

- Location: Portland, Oregon, United States

by demux » 10 May 2017 21:26 by demux » 10 May 2017 21:26

GWiens2001 wrote:

Yep, that's the idea I was thinking of. At least the general concept. In my mind the upper most pins in that diagram would be closer in size/mass to the key pins, if my basic understanding of the physics is correct that should result in the least movement of the rest of the stack. (Yes, I realize that would limit the sizes of key pins you could do this on to just the smaller ones, but if you did this in even a few of the chambers and it works as expected, it should make the lock much more difficult to bump).

-

demux

-

- Posts: 523

- Joined: 27 Apr 2017 11:14

- Location: Indiana, USA

by Robotnik » 10 May 2017 21:27 by Robotnik » 10 May 2017 21:27

-

Robotnik

- Supporter

-

- Posts: 668

- Joined: 3 Aug 2014 16:21

- Location: Portland, Oregon, United States

by demux » 11 May 2017 8:49 by demux » 11 May 2017 8:49

Well, then, there ya go. Guess I didn't use the right search terms to find that thread initially.  Goes to show why it's good to ask first though, if this has already been disproved I won't bother pinning up cylinders and trying it.

-

demux

-

- Posts: 523

- Joined: 27 Apr 2017 11:14

- Location: Indiana, USA

by Shackle Jackal » 11 May 2017 18:39 by Shackle Jackal » 11 May 2017 18:39

Every time I think i have a new technique, new tool, new design I find that "it" is already on here, or on KP.  Its a very dangerous thing, to know what your doing. - Murderface

-

Shackle Jackal

-

- Posts: 89

- Joined: 28 Jun 2016 20:58

- Location: New Mexico

by demux » 12 May 2017 8:44 by demux » 12 May 2017 8:44

Shackle Jackal wrote:Every time I think i have a new technique, new tool, new design I find that "it" is already on here, or on KP.

Yeah, I've found some interesting stuff on both. Guess my search-fu was just not strong enough earlier this week.  Thanks all for chiming in though. It'd be pretty cool if someone with access to a high speed camera would film and post actually bumping a cutaway lock. Tried searching YouTube for various combinations of "bump", "cutaway", "high speed", "slow motion", etc, and all I keep getting is the Master BumpStop animation...

-

demux

-

- Posts: 523

- Joined: 27 Apr 2017 11:14

- Location: Indiana, USA

by GWiens2001 » 12 May 2017 9:26 by GWiens2001 » 12 May 2017 9:26

demux wrote:It'd be pretty cool if someone with access to a high speed camera would film and post actually bumping a cutaway lock. Tried searching YouTube for various combinations of "bump", "cutaway", "high speed", "slow motion", etc, and all I keep getting is the Master BumpStop animation...

There are numerous people on YouTube that do high speed videos. My son watches them all the time.  You might make a cutaway lock with as little cut away as possible, yet still showing the entire pin channel, and send it to them with a bump key and hammer. Am sure they would be happy to make the video and post it on YT. Then you could post a link to their video here.  Gordon Just when you finally think you have learned it all, that is when you learn that you don't know anything yet.

-

GWiens2001

- Site Admin

-

- Posts: 7619

- Joined: 3 Sep 2012 16:24

- Location: Arizona, United States

Return to Lock Bumping

Who is online

Users browsing this forum: No registered users and 7 guests

|