It is a tubular padlock.

Inside the shackle toe hole, there should be (but in this case, isn't because it is missing) a screw that you would need to remove as the first step in disassembly of the padlock.

Since the screw is removed, now take the padlock by the shackle and rap it sharply on a hard piece of metal or wood with the side of the lock body that has the shackle toe hole facing down. This is to slide the core retaining pin away from the core.

OK, no luck. Knock harder. Nope. OK, so the pin is stuck. Soak it overnight in rust penetrant, then blow out the penetrant and retry. Nope. Another six hours and retry.

Hurrah! The pin is starting to move. Get that piece of oak out and knock the tar out of it until that pin moves far enough for the core to be removed. Not that the core wants to come out. More soaking in penetrant through the shackle holes. Knocking at an angle downwards, leaving space for the cylinder to move. Slight moving, more knocking, put the key in and turn (so the tab on the key can be used to pull) and work the key/core out. You may need to knock the living c**p out of it.

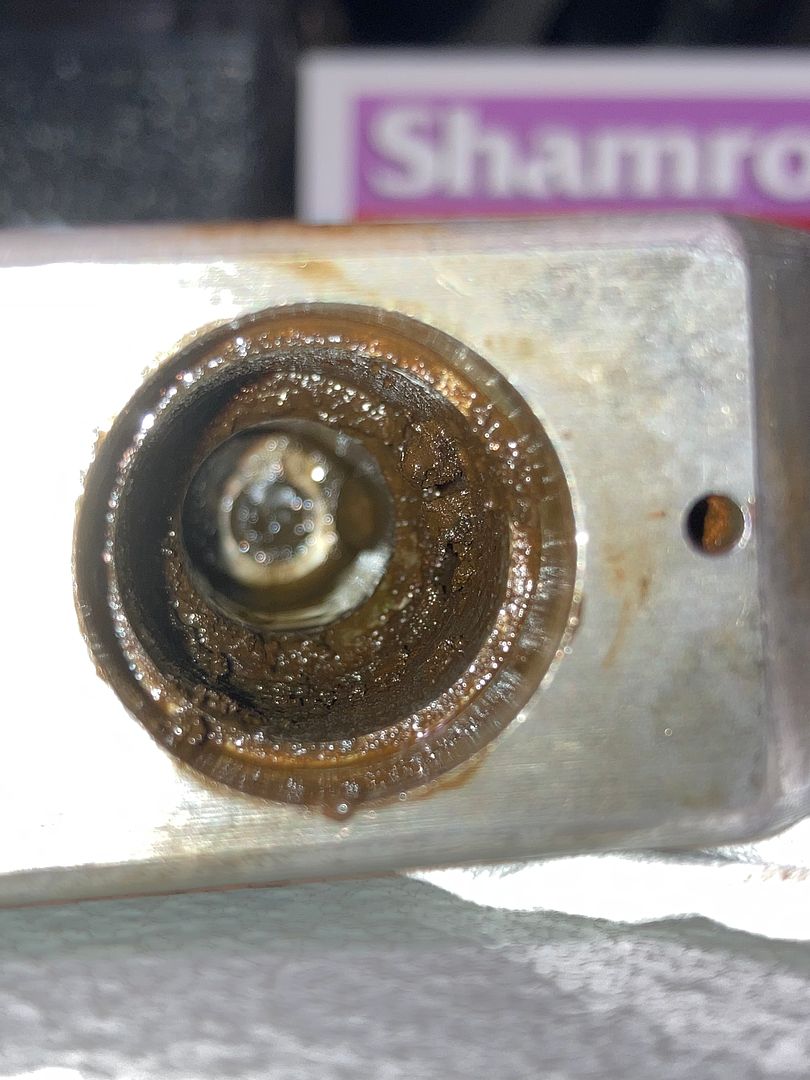

Yikes! This may explain why there were problems. How about a closer look...

Quite the slurry of rust and dirt. Chunks and bits. Perhaps a bit of cleaning is in order. What do you think?

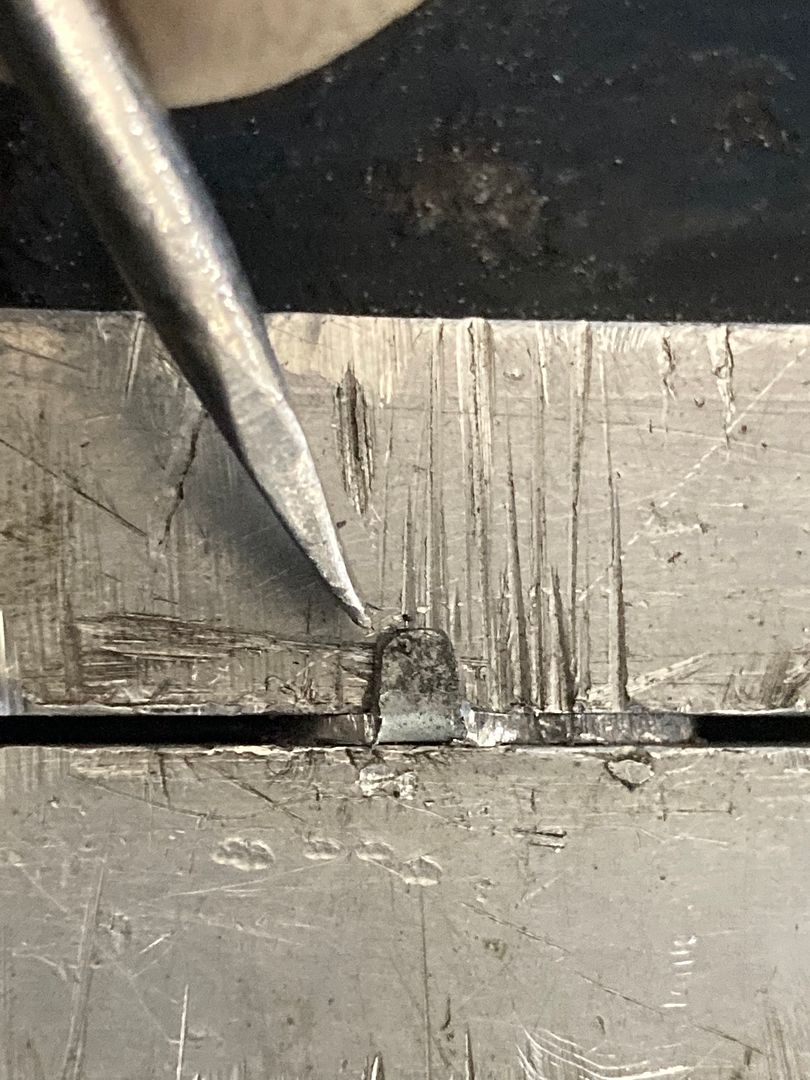

Well... we seem to have found the problem. No, not the wallowed out center of the driver from wear. The other problem See the shiny spot along the edge?

From the side, you can see a slight point with the shiny point in the top area...

There is supposed to be a tab sticking up there so it can work as the actuator between the back of the lock cylinder and the cam. That stub was all that was left to keep the lock cylinder actuating the cam lock. No wonder it was skipping! Lucky it was working at all.

OK, now we have a broken part for a lock that has not been made in a long time. Are parts available? Well, I can't find them. So guess it is time for some locksmithing.

First, found a flat washer of the correct thickness with a hole only slightly larger than the narrow width of the part to be duplicated. No, slightly larger is not acceptable, but we will deal with that.

Put the part to be duplicated onto the washer.

Now get some spray paint...

Yeah, I know, why is there spray paint on the washer, but not the original part. That is because I already cleaned off the paint before remembering that I had not taken a picture with the paint.

Anyway, remove the original part, and you have most of a pattern.

Now scrape the paint where the tab that was worn/broken off the original part should be located.

Remember how that hole was too large in diameter? Time to correct that. Use a flat ended punch and hammer to peen two opposite sides of the hole in towards each other. Trust me, it works.

Better. Now let's square up the corners and get the length correct with a file. How far? The pattern!

Here we go... much better!

Place the part in a vise. When doing work like this where I don't want the part or lock disfigured by the teeth of the vise, I use vise inserts that are simply aluminum angle iron cut to the length of the vise. Use a cutoff wheel to trim away most of the steel to get down close to the pattern.

Clean up and dress the edges with a file.

Well, here is the almost completed part.

Almost completed? Yes. Almost. That tab needs to be bent up so it can drive the cam.

Place the driver into the vise with only the tab sticking above the jaws.

Remember the flat ended punch and hammer? Grab them and use them to bend over the tab. Keep the punch down low close to the vise jaws and tap with the hammer. As the tab bends, lift it so the angle stays just slightly past being flat to the metal tab. You want the base of the tab to bend, not the middle or top.

Once it is flat...

... the part is done!

Reassemble and you are done.

In case you are unsure, the hook on the spring will grab the side of the lock cylinder, and that driver tab will ride on the side of the cam.

Too tired now to take the lock apart again for other pics, but will do and post a disassembly and reassembly post on this lock in the near future as I can not find any information on it.

Gordon