It will be a shortened explanation as I don't think it is entirely essential to show actually driving out the roll pin to disassemble the core. (OK, OK... I forgot to start taking pictures until I had the locking bolt removed from the cylinder and had already shimmed the plug).

This is what the lock looks like:

To get the cylinder assembly removed from the puck lock, first pick the lock, then back out this screw so you can slide out the cylinder.

Use a drift punch and drive out the roll pin attaching the locking bar to the back of the cylinder.

Shim the plug.

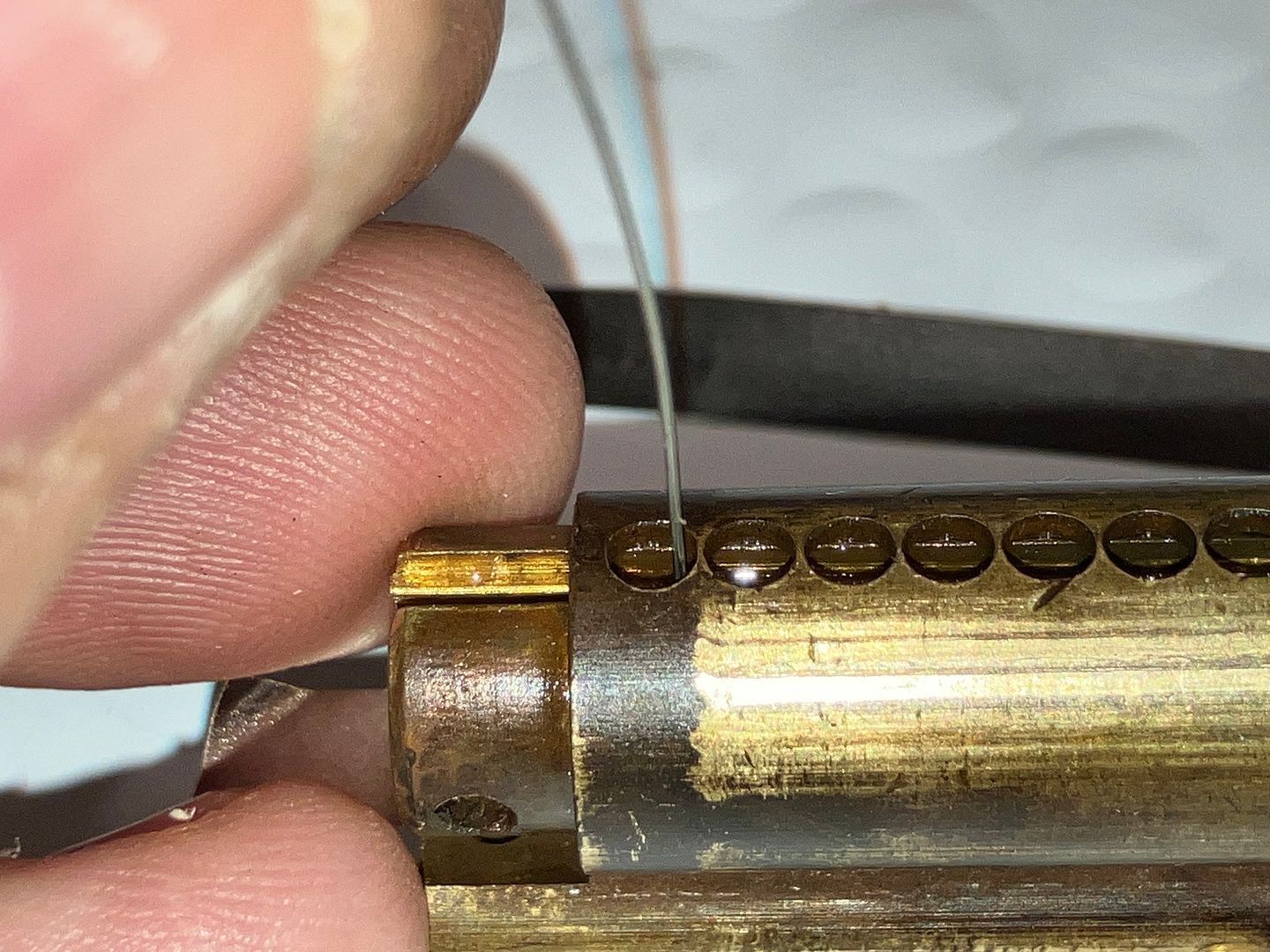

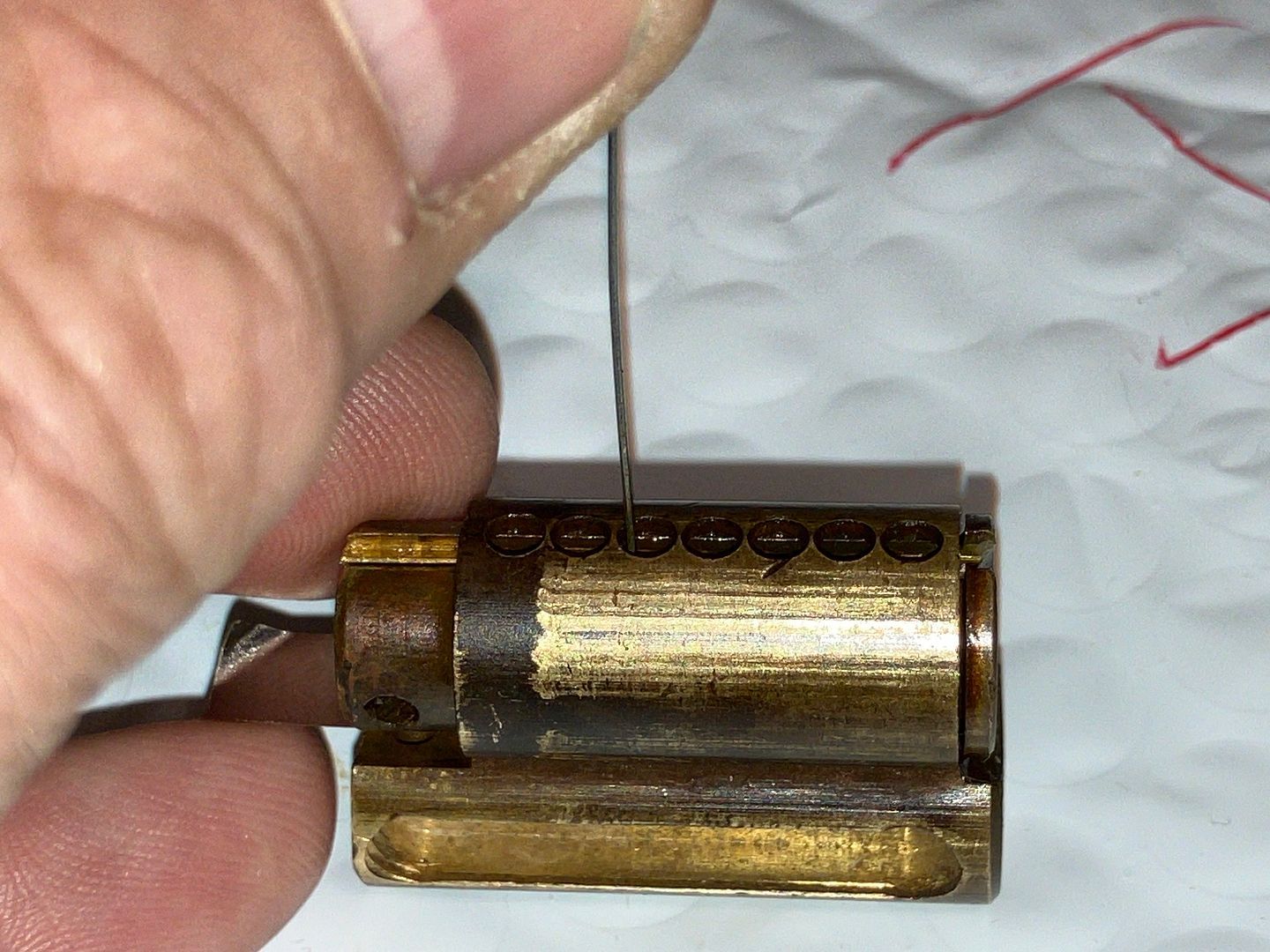

Count the holes: Seven of them. Six pins for the key and the seventh is for the retaining pin that keeps the plug in the housing AND prevents turning the cylinder the wrong way or too far the right way.

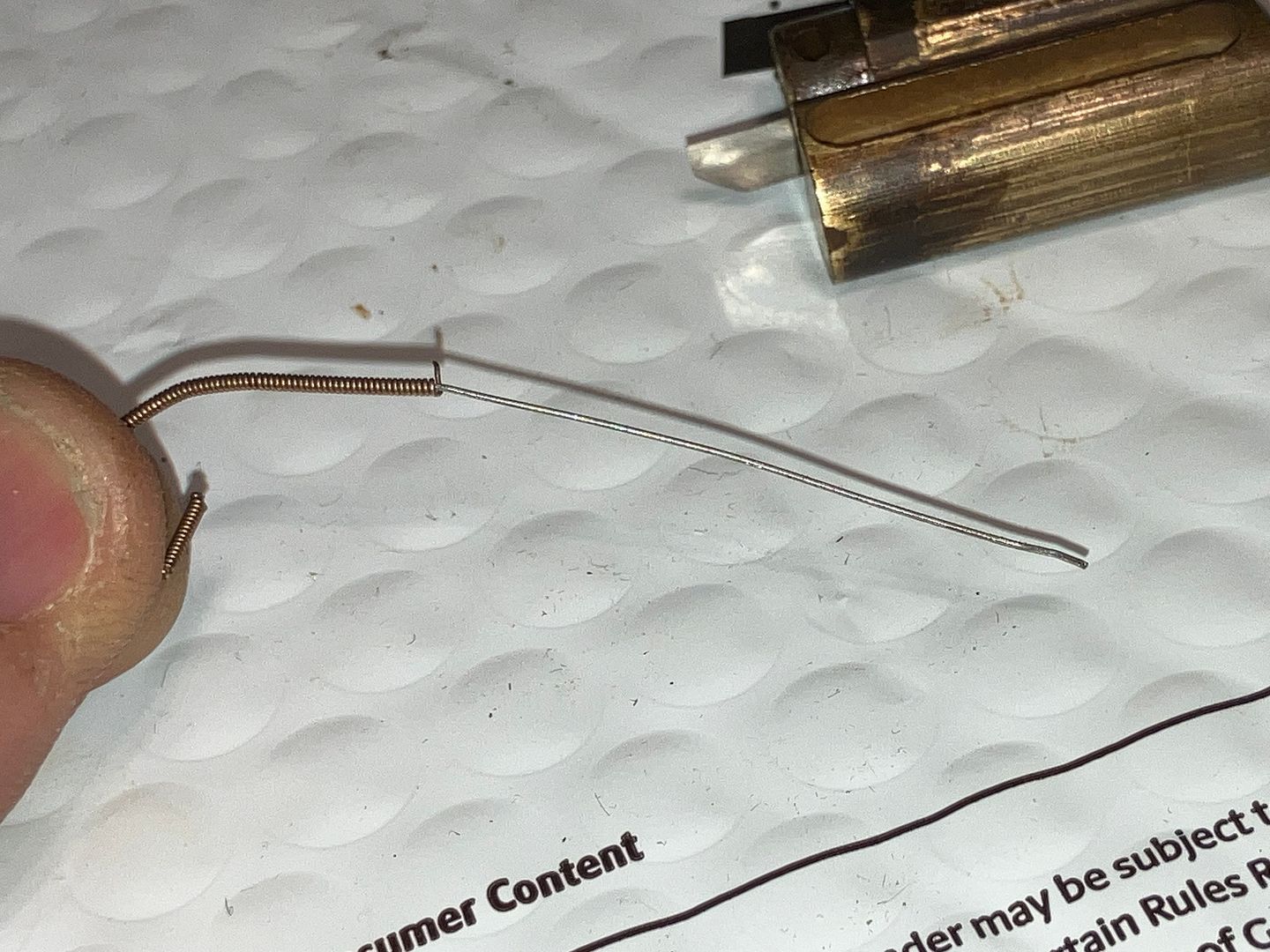

How to lift the pins, especially that seventh pin. Well, it requires a highly specialized tool.

Yep. A piece of guitar wire. Strip back the bronze windings from a base string and you will have a perfect piece of center wire that is strong enough to push in the pins yet thin enough to bypass the wards of the keyway. I have found that doing this negates the need to drill that last channel through the plug to push up the retaining pin.

Push in the seventh pin and once it is lifted high enough, shim it from the back.

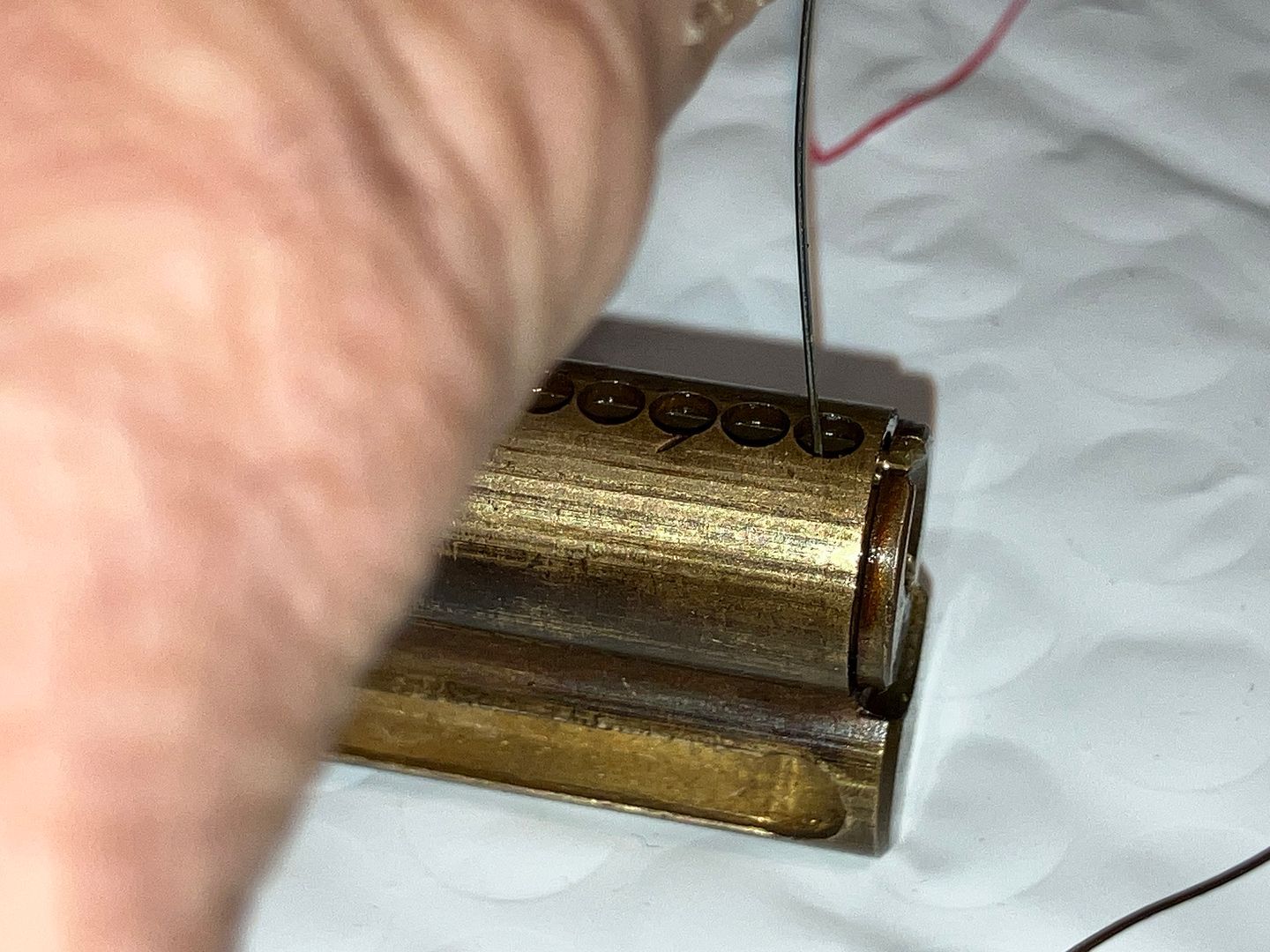

Repeat for the remaining pin chambers.

When you get the last one shimmed...

You can slide the plug forward a bit.

Now get a properly sized follower (can be found in your drill bit set)

And slide out the plug. Keep the shim going all the way through the housing and leave it in place even with the follower (drill bit) in place. Do NOT turn the plug counter-clockwise. You will see why soon.

Different views of the plug...

Aren't those pins such a fabulous fit? Wow, the quality of workmanship is astounding.

If you look at that last picture, you can probably see why you don't want to turn the plug counter-clockwise. The drivers and springs will pop into that cut-away area bricking the cylinder.

This is the stop-end of the retaining pin channel/groove that limits the rotation of the plug.

Stick in a blank and you can see how far you need to cut down the key for each bitting position.

.

.I think (hope) you can figure out reassembly. Tip... scroll backwards through the post above!.

Hope this helps someone out!

Gordon