|

Picked all the easy locks and want to step up your game? Further your lock picking techniques, exchange pro tips, videos, lessons, and develop your skills here.

by Druis2264 » 27 Aug 2005 14:59 by Druis2264 » 27 Aug 2005 14:59

Yeah, I looked up on these and I was attempting to get 'em set. I push up on them and the tension wrench moves ever so slightly and I don't really know what to do... I watched a video on like letting the plug move back and allowing it to set, but when I do that, even if I'm doing it extremely minutely, it'll reset a bunch of pins. Anybody have advice on the technique to get the sec pins into place during that particular situation.

-

Druis2264

-

- Posts: 17

- Joined: 23 Aug 2005 2:36

by stick » 27 Aug 2005 15:15 by stick » 27 Aug 2005 15:15

You know that when you let the plug move back, it's as you press on the spool pin, right? Releasing tension is only part of it.

-

stick

-

- Posts: 617

- Joined: 31 Mar 2004 23:55

by Druis2264 » 27 Aug 2005 15:19 by Druis2264 » 27 Aug 2005 15:19

Yes, I push on it, and let it move back, further and further and further but it doesn't click... well it does but then everything else just falls out. And I read that that's when you're supposed to like, look for other pins and finish the rest, but my lock like wants it to be pushed down a certain way...

-

Druis2264

-

- Posts: 17

- Joined: 23 Aug 2005 2:36

by stick » 27 Aug 2005 15:30 by stick » 27 Aug 2005 15:30

If continuing to lift the spool pin past the false set causes the other pins you've already set to unset, then just fully set the spool pin, and you'll be able to pick the other pins normally again. This is, of course, only if you're doing it right in the first place.

-

stick

-

- Posts: 617

- Joined: 31 Mar 2004 23:55

by tshock » 27 Aug 2005 19:37 by tshock » 27 Aug 2005 19:37

What type of lock are you working with? A fortress 40mm?

-

tshock

-

- Posts: 86

- Joined: 8 Jul 2005 21:32

- Location: Alabama

by Druis2264 » 27 Aug 2005 20:05 by Druis2264 » 27 Aug 2005 20:05

Masterlock 140

-

Druis2264

-

- Posts: 17

- Joined: 23 Aug 2005 2:36

by tshock » 27 Aug 2005 20:14 by tshock » 27 Aug 2005 20:14

When I first leaned how to pick spool pins I had the same problem. Truthfully one day it just clicked and I got it right. All I can say is that you need to use super light tension. Also the pin that is the hardest to push down might not be the right pin to push on. Make sure you test/feel all of the pins.

Other than that it just takes alot of practice.

-

tshock

-

- Posts: 86

- Joined: 8 Jul 2005 21:32

- Location: Alabama

by Druis2264 » 27 Aug 2005 21:15 by Druis2264 » 27 Aug 2005 21:15

Yeah, I tested all the pins, I'm pushing on the really soft one and just the slightest decrease of tension drops all the spools.

-

Druis2264

-

- Posts: 17

- Joined: 23 Aug 2005 2:36

by stick » 27 Aug 2005 21:47 by stick » 27 Aug 2005 21:47

If you're pushing on the softest one, then you're not understanding the basics of lock picking.

-

stick

-

- Posts: 617

- Joined: 31 Mar 2004 23:55

by Druis2264 » 27 Aug 2005 23:36 by Druis2264 » 27 Aug 2005 23:36

... what? I'm doing it to the best of my knowledge dude... I'm not just plain pushing on the softest one. I used my pick and explored the rest of the lock. I pushed the first pin in and then gently touched the back pin, which sets my particular lock into the "resting on sec pins" mode, then there are the second and third pin locked tight. But one gives ever so slightly more than the other, and I read and watched a vid that that's the one you're supposed to push on, the one that, if pressure is applied, rocks the cylinder back slightly. Geeze man, give me a break I just started lockpicking maybe... 6 days ago... I'd say I'm doing decent.

-

Druis2264

-

- Posts: 17

- Joined: 23 Aug 2005 2:36

by stick » 28 Aug 2005 1:09 by stick » 28 Aug 2005 1:09

You don't need to take offense at everything so quickly. If you didn't understand my second post in this thread, here's an attempt at clarification through Paint.

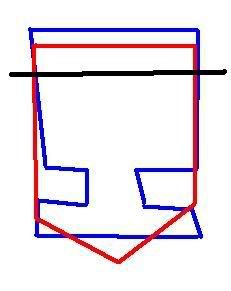

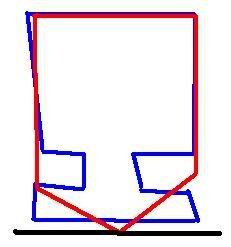

Here are the top pins for a two pin lock. The red one is closer to us and is a standard top, the blue is farther and is a spool. The black line is the shear line.

Say the first pin sets first, as seems to be the case for you.

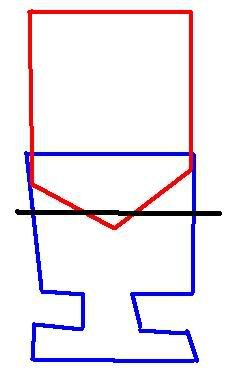

Next, you false set the security pin.

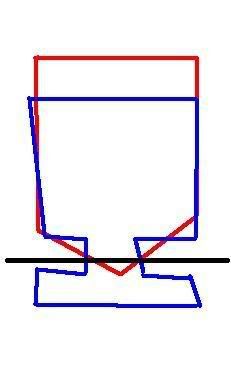

If you continue to lift the security pin past the false set, however, the first pin may become unset; let it unset, and completely set the security pin.

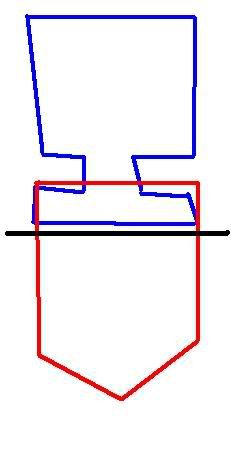

Now that you've completely set the security pin, you can set the normal pin normally, and it'll pick.

This is how it'd work with a two pin lock. With a Master 140, which has 4 pins, 2-3 of which will be spools, you may have to do a bit of jumping around between pin stacks, setting security pins which'll cause others to unset. Keep at it, remember to use light tension, and you'll get it. Picking Varjeal's cutaway from before (5 spools, 1 serrated) was a nightmare with the constant setting and unsetting, but with patience, practice, and the right tension, it'll get much easier.

-

stick

-

- Posts: 617

- Joined: 31 Mar 2004 23:55

by Ben WV » 17 Sep 2005 13:18 by Ben WV » 17 Sep 2005 13:18

This "super light tension" that everybody preaches is exactly the thing that prevevented me from succeeding with spool pins for a long time. Of course you would be overdoing it if your tension was so hard that you couldn't even feel the reverse pressure starting. But your torque has to be firm, not light.

I decided a couple weeks ago to really master the schlage grade 1 deadbolt, and I set up a plan to open it a total of 800 times and discover what the heck was preventing me from succeeding with these locks. So I loaded it with 2 pins in three different configurations and picked it 100 times in each. Then I moved to three pins in two configuratios for 100x each, followed by the same with four pins in two configuratrions. FInally, I loaded it fully and picked it 100 times in both directions.

Now I can open these locks in an average time of 30 seconds either way. And I learned two important things in this process. 1) I was overlifting like a fiend, and needed to create an assortment of hooks that were graduated in height. 2) The "whisper-of-tension" gospel is totally counterproductive BS. It's definitely possible to overdo it, but in general, you need more tension on locks with security pins than you would need on a lock with flat pins.

-

Ben WV

-

- Posts: 29

- Joined: 24 Jan 2005 19:49

by Keyring » 17 Sep 2005 13:38 by Keyring » 17 Sep 2005 13:38

2) The "whisper-of-tension" gospel is totally counterproductive BS. It's definitely possible to overdo it, but in general, you need more tension on locks with security pins than you would need on a lock with flat pins.

I couldn't agree with you more. The other point is that, if you are raising a spool pin, you have much more control if the pick is working as a lever against the bottom of the keyway. In other words (say we're using a hook) once you've found the bottom of the spool pin which you want to raise next, you pull down the pick handle till part of the pick is resting at the bottom of the keyway opening, and use that as a lever. You can now FEEL the pin rising, and so you don't push it too far.

-

Keyring

-

- Posts: 486

- Joined: 23 Mar 2004 8:01

- Location: uk

-

by Mad Mick » 19 Sep 2005 18:59 by Mad Mick » 19 Sep 2005 18:59

Keyring wrote:2) The "whisper-of-tension" gospel is totally counterproductive BS. It's definitely possible to overdo it, but in general, you need more tension on locks with security pins than you would need on a lock with flat pins.

I couldn't agree with you more.

I beg to differ here...

Light tension is required, in order to allow the plug to counter-rotate against the tension applied, and allow the false-set spool to set correctly. If you are experiencing many multiple resets, the obvious answer is that the picking order is not correct. Using Druis2264's Master 140 as an example, there can be from one to three spools in this four pin lock...

For plug alignment, the first visible pin will always be standard. Set this one first, noting how much the plug rotates. Very slight rotation means that there are other standard pins. Test the rest...and set the ones that are binding. Once you encounter a noticeable difference in the amount the plug rotates, the remaining pins are spools.

Example:

Pin one sets, allowing the plug to rotate minimally. Testing of the remaining (three) pins finds pin three to be hard bound and two & four springy. Setting pin three results in the plug rotating approx. five degrees more, then all four pins appear bound to a certain degree. Heavy (or anything other than light) tension, in this situation, is not going to help much. Both the remaining unset pins (two and four) are very likely to be spools, and require light tension to allow them to counter-rotate the plug against tension applied.

Now, the choice has to be made between pin two, or four. Which should be set first? Trial and error...

Set pin two, and pins one & three reset. Set pins one & three again, then approach pin four...

Setting pin four makes the whole lot reset...

Setting pin two wasn't the correct choice...the next cycle of picking would be:

Apply light tension, set pin one, test the other pins and set (standard) pin three. Set the false-set pin four, which resets pins one and three. Reset pins one and three, then set pin two and open the lock.

This is just an example, use it or ignore it.

IMHO, heavy tension has it uses when reverse-picking or overlifting, but for general purposes, a light touch is preferable.  If it ain't broke.....pull it down and see how it works anyway!

-

Mad Mick

-

- Posts: 2314

- Joined: 8 Jan 2004 19:19

- Location: UK

Return to Pick-Fu [Intermediate Skill Level]

Who is online

Users browsing this forum: No registered users and 6 guests

|