When I started this biz in the early 70's I had only a Taylor key assortment and the board it came on. A 2 x 3 little thing with double hooks and of course 100 different key numbers about 5 of each. Of course that grew and when we had the shops we had over 4000 key numbers and tons of junk which never went anyplace which we had picked up from hardware stores which went out of biz, a few locksmith estate sales, and other out of the way places I did buy odd, read that sectional, keys. I still have a ton of old sectionals which I will never use, but they are part of the firm so today they sit on separate 2 x 4 boards down here up against one odd wall.

From the shops with the 16 feet of keys to today's 4 x 12 down here has been a long haul. This is today's board down here in the bunker .....

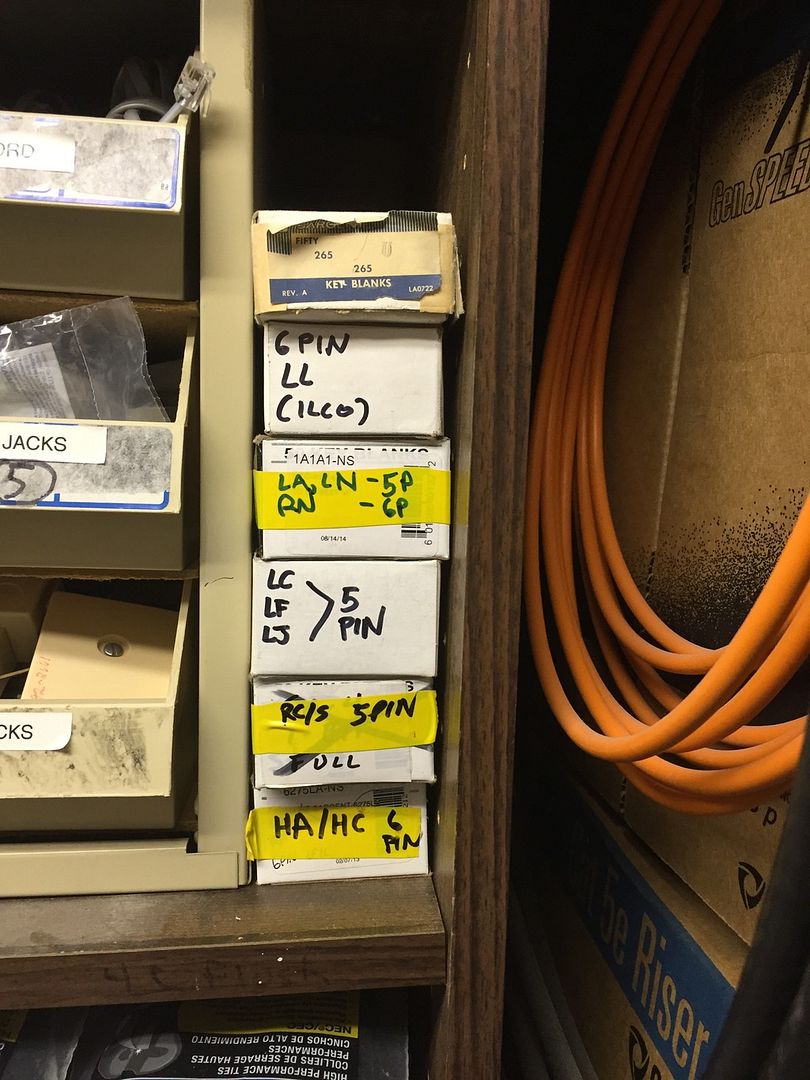

Looks a bit crowded, and disorganized, but know it is not. There are no car keys or junk up here. Mostly it is the stuff I cut every day and that group is in the middle of the board, with a galaxy of the supporting keys around it. Those are set up in the usual "Ilco" key number method by using the catalog and going from A to Y in order, by manufacturer and number. The popular ones of that are in the middle.

Best IC are stored only in boxes right behind the Framon. When I need to cut them I bring in the A1 punch, and pull stock. Medeco, and all the other high security keys are in the lower left of the Framon as either the 339 or the #2 will be used for cutting them only. Safe deposit keys are above the 9 as that is where they are cut. (Lower right on the board behind it.)

In front of the board is our main key machines -- starting with the closest one to you, a Curtis #9 which we bought new in 1974. Next to that is my Framon #2, then a Craftsman grinder with a wire wheel on one side and a fine grinding wheel on the other for just about everything which needs what final "touch" or resharpening. Beyond that the motor room gets fuzzy. The ESP 339 is next, which I make the high security keys on like side winders, ACE, and cutting the side bar cuts on Jet Primus series keys. I also use this to remill existing blanks to make up keys which I don't have. Beyond that is a HPC Speedex out of the old truck - it has those center grip vises for double sided keys which most seem to have trouble with.

Also down here but not seen are tons of old machines out of the shops -- Curtis 2000 auto, the Jet 2000 which doesn't cut ACE, Curtis #2 which is today "junk" but I still could use some of the parts for the 9 if I needed it. A long worn out Scotsman, and I don't know how many boxes of ACE keys we cut on that thing. AND of course an Ilco #8 Dynamite which is in the show room, as it was one of our earliest machines and the spare Foley 200s. I have a few of those from friends over the years who just wanted someplace to toss the things, and I use them for parts for the one in the van today. Also not seen is the hand punch to cut Schlage double sided wafer keys. That hangs on the board, and if I ever use it again ... there is also one in the van, again -- who still cuts those 1307A or 1307W keys?

More when I do the van's key stuff, maybe later on.

Sinifar